Top 10 Ceramic Materials with the Highest Thermal Conductivity

Introduction

Thermal conductivity plays a crucial role in various industries, influencing heat transfer efficiency and thermal management. High thermal conductivity is a desirable characteristic in materials, especially in applications where effective heat dissipation is essential. Among the diverse range of materials, ceramics stand out for their unique combination of properties, including high thermal conductivity. In this comprehensive guide, we will explore the top 10 ceramic materials renowned for their exceptional thermal conductivity and delve into their applications across different industries.

10 Typical High Thermal Conductivity Ceramic Materials

1. Beryllium Oxide (BeO): ~230-330 W/mK

Beryllium Oxide (BeO) stands out with one of the highest thermal conductivities among ceramics. Its excellent thermal properties make it suitable for demanding applications where efficient heat dissipation is crucial.

Applications:

- Aerospace: BeO is widely used in the aerospace industry, where its combination of high thermal conductivity and lightweight properties is advantageous. It contributes to the production of components in spacecraft and satellites.

- Electronics: In the electronics industry, BeO is employed in the manufacturing of high-performance electronic devices, particularly those requiring effective thermal management, such as transistors and integrated circuits.

Further Reading: An Introduction to Beryllium Oxide Ceramics

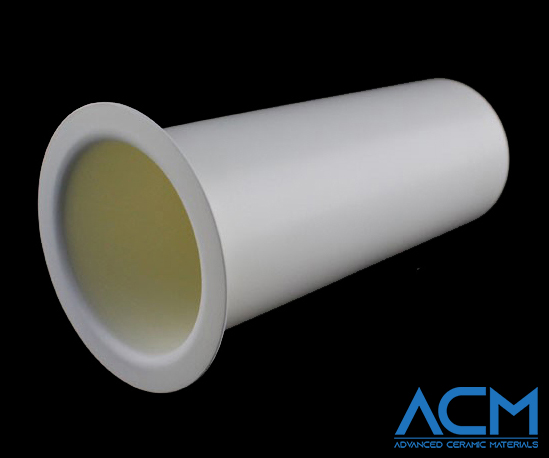

2. Aluminum Nitride (AlN): ~150-250 W/mK

Aluminum Nitride (AlN) is a ceramic material prized for its high thermal conductivity and excellent electrical insulation properties. With a thermal conductivity ranging from 150 to 250 W/mK, AlN is widely used in applications where efficient heat dissipation is crucial.

Applications:

- Electronics: AlN is commonly utilized in the production of substrates for high-power-density electronic devices. Its combination of thermal conductivity and electrical insulation makes it valuable in the semiconductor industry.

- LED Lighting: In LED technology, AlN is employed for its thermal management properties. It helps dissipate the heat generated by LEDs, ensuring optimal performance and longevity.

Further Reading: What is Aluminum Nitride Ceramic?

3. Silicon Carbide (SiC): ~120-250 W/mK

Silicon Carbide (SiC) is a ceramic material renowned for its extremely high thermal conductivity, mechanical strength, and chemical stability. With thermal conductivity ranging from 120 to 250 W/mK, SiC is a versatile material in demanding applications.

Applications:

- High-Power Density Electronics: SiC is extensively used in the heat dissipation and packaging of high-power density and high-frequency electronic devices. Its thermal and electrical properties make it suitable for power electronics and radio frequency (RF) applications.

- Aerospace: The aerospace industry benefits from SiC's lightweight nature and ability to withstand high temperatures. SiC components contribute to the efficiency and reliability of aerospace systems.

Further Reading: An Overview of Silicon Carbide Ceramic Materials

4. Copper Aluminum Oxide (CuAlO2): ~100-200 W/mK

Copper Aluminum Oxide (CuAlO2) is a unique ceramic material that exhibits notable thermal conductivity, along with a combination of other desirable properties such as electrical conductivity.

Applications:

- Electronics: CuAlO2 finds applications in electronic and thermal management systems where both thermal and electrical properties are essential. Its dual conductivity nature makes it suitable for certain specialized electronic components.

- Thermal Management: In industries requiring effective heat transfer, CuAlO2 can be employed in various thermal management applications, ensuring efficient heat dissipation.

5. Boron Nitride (BN): ~20-300 W/mK (depending on type)

Boron Nitride (BN) is a ceramic material with unique properties, and its thermal conductivity can vary significantly depending on its structural form. Two primary types of Boron Nitride are commonly recognized:

- Hexagonal Boron Nitride (h-BN): With a structure similar to graphite, h-BN exhibits high thermal conductivity along its planar layers. This type of BN can showcase thermal conductivity values in the range of 20-300 W/mK. It is often used as a lubricant, insulator, or in applications where its high thermal conductivity is beneficial.

- Cubic Boron Nitride (c-BN): Boasting a crystal structure similar to diamond, c-BN can exhibit thermal conductivity values comparable to h-BN. This type of BN is renowned for its hardness and is commonly utilized in cutting tools and abrasive applications.

Applications:

- Electronics Industry: Hexagonal Boron Nitride's high thermal conductivity makes it suitable for use in electronics, especially in the production of thermal management components such as heat sinks and insulating layers.

- Metallurgical Engineering: The excellent thermal properties of Boron Nitride find applications in metallurgical processes where high-temperature stability and efficient heat transfer are crucial.

- Aerospace: The aerospace industry benefits from BN's combination of thermal conductivity and electrical insulation, making it valuable in various components, including insulating coatings for spacecraft.

Further Reading: Boron Nitride Overview: Properties, Production, and Uses

6. Titanium Diboride (TiB2): ~60-70 W/mK

Titanium Diboride (TiB2) exhibits moderate thermal conductivity and is recognized for its high-temperature stability. It is often chosen for applications where both thermal and mechanical properties are critical.

Applications:

- High-Temperature Applications: TiB2 is employed in high-temperature environments, such as crucibles for molten metal processing. Its stability and resistance to extreme conditions make it suitable for these applications.

- Ceramic Cutting Tools: TiB2's hardness and resistance to wear make it valuable in the production of cutting tools for machining hard materials, contributing to enhanced tool life and efficiency.

7. Magnesium Oxide (MgO): ~40-60 W/mK

Magnesium Oxide (MgO) is known for its moderate thermal conductivity and is valued for its electrical insulation properties. It finds applications in various industries requiring both thermal insulation and stability.

Applications:

- Power Electronics: MgO is commonly used as electrical insulation in power electronics. Its thermal properties contribute to the efficient functioning of electronic components, preventing overheating.

- Refractory Materials: MgO is utilized in refractory materials, providing thermal insulation in high-temperature environments. It ensures stability and longevity in applications like furnace linings.

Further Reading: Magnesium Oxide Ceramic Materials - An Overview

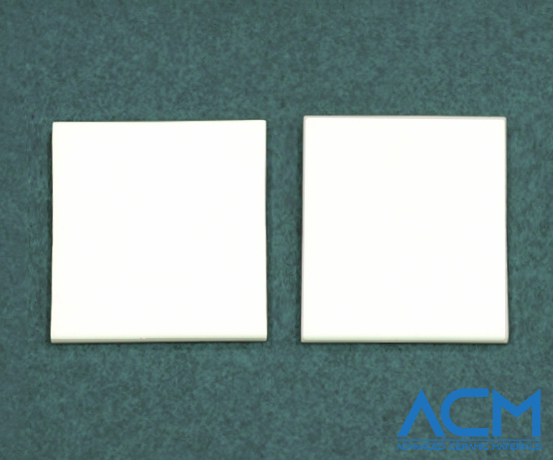

8. Alumina (Al2O3): ~20-40 W/mK

Alumina (Al2O3) is known for its good insulation performance and mechanical strength. Its thermal properties, although moderate, find diverse applications in various industries.

Applications:

- Power Electronics: Alumina is widely used in power electronics for its electrical insulation properties. It contributes to the manufacturing of insulating components in semiconductors and electronic devices.

- LED Lighting: In the LED lighting industry, alumina is utilized for its thermal conductivity in heat sinks. It aids in dissipating the heat generated by LEDs, ensuring optimal performance.

Further Reading: Everything You Need to Know about Alumina Ceramics

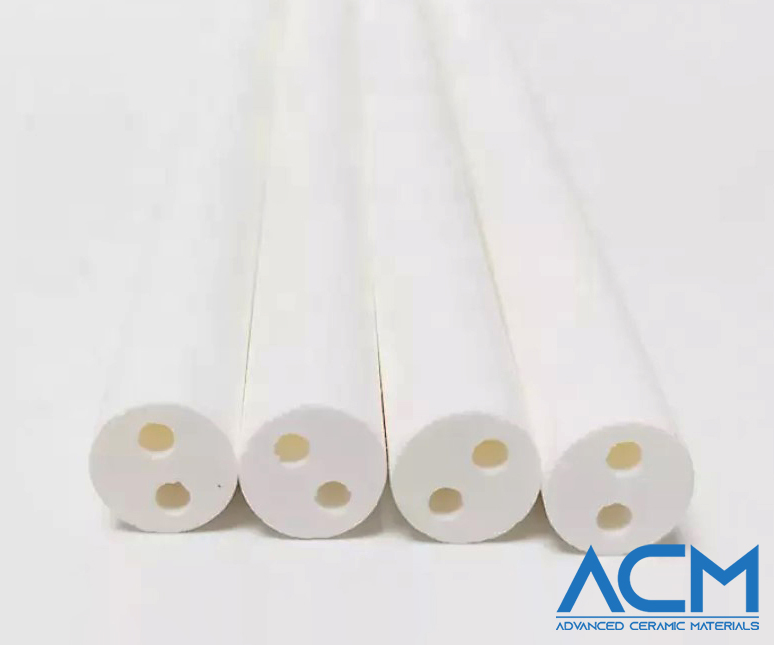

9. Silicon Nitride (Si3N4): ~20-40 W/mK

Silicon Nitride (Si3N4) is recognized for its excellent mechanical strength and chemical stability. Its moderate thermal conductivity makes it suitable for high-temperature and high-voltage electronic applications.

Applications:

- High-Temperature and High-Voltage Electronics: Si3N4 ceramics are utilized for packaging and heat dissipation in electronic devices operating in challenging environments. Their properties contribute to the reliability and efficiency of such devices.

- Research Focus: Si3N4 ceramics have gained attention from researchers due to their outstanding properties, including high toughness, strong thermal shock resistance, good insulation, corrosion resistance, and non-toxicity.

Further Reading: An Overview of Silicon Nitride Ceramics

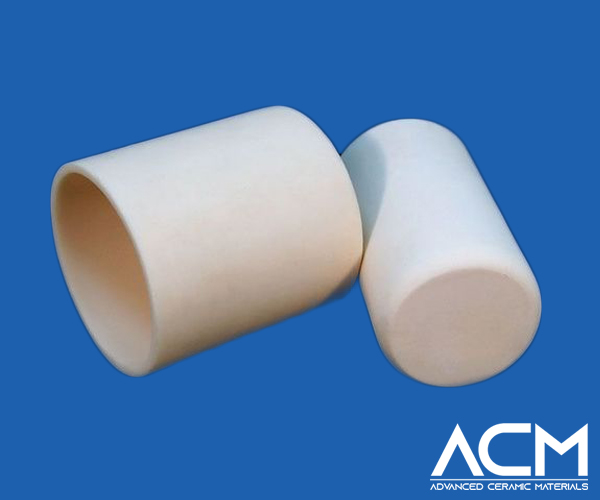

10. Zirconia (ZrO2): ~2-3 W/mK (yttria-stabilized zirconia can have higher values)

Zirconia (ZrO2), in its unstabilized form, possesses a moderate thermal conductivity in the range of 2-3 W/mK. However, when stabilized with yttria, zirconia's thermal conductivity can be significantly enhanced, offering improved performance in various applications.

Applications:

- High-Temperature Electronic Devices: Yttria-stabilized zirconia is often preferred in the packaging and heat insulation of high-temperature electronic devices. Its good mechanical strength and chemical stability contribute to the stability of electronic components in extreme conditions.

- Biomedical Engineering: In biomedical applications, yttria-stabilized zirconia is utilized for its biocompatibility and resistance to corrosion. It finds use in dental implants and other medical devices where both thermal stability and compatibility with the human body are essential.

- Enhanced thermal conductivity in yttria-stabilized zirconia broadens its applicability across industries, offering a versatile solution for applications demanding both thermal and mechanical performance.

Further Reading: Zirconium Oxide Ceramic & Its Uses

Conclusion

In conclusion, these top 10 ceramic materials with exceptional thermal conductivity play pivotal roles in various industries, from aerospace to electronics and beyond. Their unique characteristics make them indispensable for applications requiring efficient heat dissipation and thermal management.

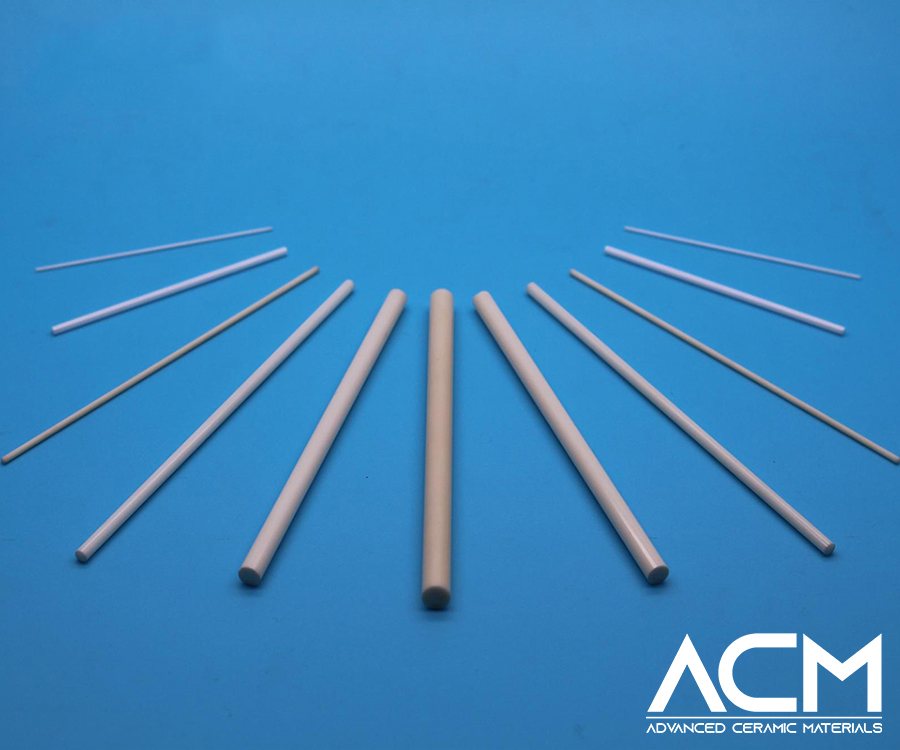

At Advanced Ceramic Materials (ACM), we take pride in being a leading supplier of high-quality ceramic materials, including Beryllium Oxide, Aluminum Nitride, Silicon Carbide, and others featured in this comprehensive guide. With a commitment to excellence, we provide these cutting-edge materials to industries worldwide, offering tailored solutions to meet diverse needs. Our extensive inventory, coupled with a dedicated team of experts, ensures that our customers receive top-notch products for their specific applications.

Discover the difference that ACM can make in advancing your projects with our premium ceramic materials. Contact us today to explore our comprehensive product range and benefit from our expertise in providing innovative solutions for your thermal management challenges.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments