Magnesium Oxide Ceramic Materials - An Overview

Magnesium oxide, also known as magnesia or MgO, is an alkaline earth metal oxide that is produced by the calcination of naturally occurring minerals. The ceramic material is an oxide of magnesium composed of magnesium and oxygen. Magnesium oxide is the most commonly used crushable ceramic because it possesses excellent thermal conductivity and is extremely resistant to electrical conductivity. MgO is a valuable material used in many applications today, one of which is its use in lowering the effect on glaze thermal expansion. In this article, you'll discover more facts about magnesium oxide, its properties, and its applications.

Overview of Magnesium Oxide

Together with SrO, BaO, and CaO, MgO belongs to the Alkaline Earth group of oxides. The compound has a cubic crystal structure. Magnesia melts at 2800 degrees Celsius, similarly to zirconia, making them the oxides with the highest melting points. MgO is known for its ability to matte glazes in larger proportions, though the mechanism for this is different at higher temperatures and low temperatures. Magnesium oxide is mainly obtained from dolomite and talc at medium and high temperatures; it is sourced mainly from dolomite and talc. But more magnesium oxide is currently produced from the calcination of naturally occurring minerals. Magnesite (MgCO3) is the most common natural source of magnesium oxide.

Other essential sources include seawater, underground deposits of brine, etc. Research shows that magnesium is the eighth-most abundant element in the earth's crust, comprising about two percent of the earth's crust, as well as 0.12% of seawater. Magnesium oxide performs excellently in high temperatures, particularly in the provision of electrical insulation.

Further Reading: Is Magnesium Oxide a Refractory Material?

Production of Magnesium Oxide

The MgCO3 and Mg(OH)2 obtained from the mineral sources of magnesium oxide are converted to oxide by calcination. The thermal treatment during the calcination process typically affects the surface area and pore size of the magnesium oxide formed. Consequently, the reactivity of oxide is equally impacted. But the level and nature of impurities present in the calcined material depend on the source of the mineral. Different types of magnesium oxide can be obtained depending on the temperature used during the calcining process. For example, dead-burned magnesium is produced at temperatures over 1500 degrees Celsius, while fused magnesia is obtained from calcined magnesia at temperatures over 2650C degrees Celsius.

Properties of Magnesium Oxide

- Good Refractoriness

- Good corrosion resistance

- High Thermal Conductivity

- Low Electrical Conductivity

- Transparency to Infrared radiation

Applications of Magnesium Oxide

There are many different applications of magnesium oxide.

Refractories

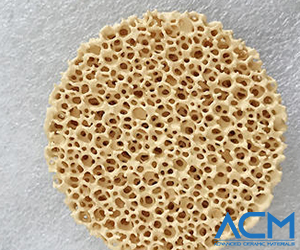

Magnesium include has always been a source for making refractory brick in the steel industry. The ceramic material is typically impregnated with carbon materials, such as tar, pitch, or graphite to enhance the properties of the finished material, especially against corrosion in environments of basic slags. Magnesia bricks are widely used in combination with spinel or chrome in ferroalloy, non-ferrous, glass and cement manufacturing industries.

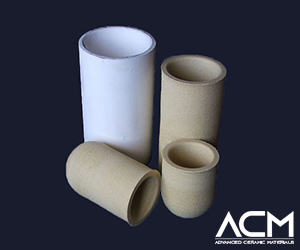

Crucibles

Magnesia crucibles are used in the superalloy, nuclear industry, and chemical industries to mitigate the corrosion of the substance. Magnesium crumbles often come in different purity grades. The addition of additives is used to promote sintering or restrict crystal growth. This includes clay, yttria, alumina, etc., depending on the application. Magnesium crucibles are generally stable in high temperatures. The temperature ranges from 1400-2400 degrees Celsius.

Brake Linings

Because of its electromechanical properties, magnesia is also used in brake linings. Its intermediate hardness ensures that the wear on metal remains sufficiently low while conducting heat from the friction contact surfaces.

Plasma Display Screens

Magnesia is used in making the protective film that covers plasma display screens. In this case, the electro-optical properties of magnesium oxide are exploited.

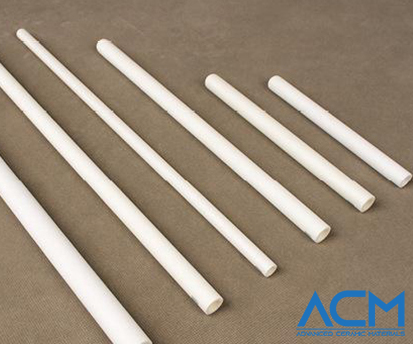

Thermocouple Tubes

Extruded magnesia protective sheaths have been produced and used to provide a protective covering to thermocouples in aggressive conditions.

Heating Elements

Magnesia powder is a very important component in heating elements. It is used as a filling for electrical heating elements for use in contact with air or liquids. Fused magnesia gives you the best electrical resistance and thermal conductivity. The MgO forms a layer between the element and the outer sheath. It also serves as mineral insulation in cables. When used as a secondary flux in high-temperature glazes, magnesium oxide melts well and can be present in glossy glazes.

Thin Film Formation

Magnesium oxide has been investigated for many electronic applications. High purity grades of magnesium oxide sputtering targets & MgO evaporation materials are useful for growing thin-film semiconductors.

Magnesium Cement

Magnesia cement is a binder used in refractories. The cement composition is based on the formulation of magnesium oxychloride. The cement is pretty fast-hardening and has several refractory and general repair applications.

Conclusion

Magnesium oxide, otherwise known as magnesium, is an important ceramic material composed of magnesium and oxide. It's known for its high thermal conductivity and strong corrosion resistance. Magnesium oxide is useful in several applications, such as refractory, crucibles, thermal engineering, and testing elements. For more information about ceramic materials, please visit https://www.preciseceramic.com/.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments