Ceramic Foam

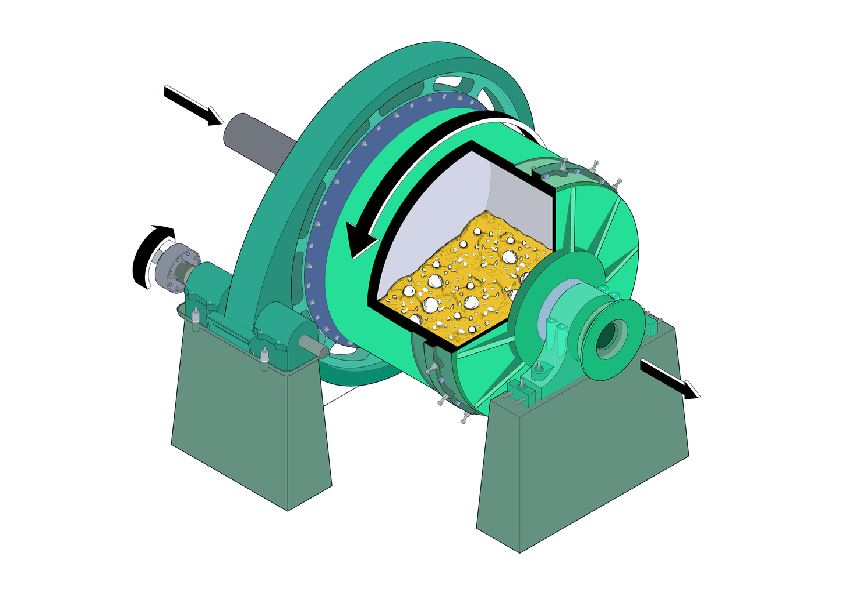

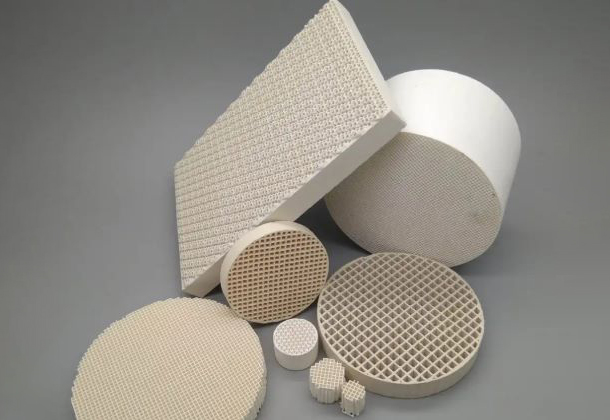

Ceramic foam is a tough foam made of ceramic. The manufacturing technique involves impregnating open-cell polymer foam with ceramic slurry inside and then firing it in a kiln, leaving only the ceramic material. Ceramic foam can be composed of several ceramic materials. Common high-temperature ceramics are alumina, silicon carbide, zirconia, and etc.

Read more: What are Ceramic Foams? Properties, Manufacturing, and Uses

Ceramic Foam Properties:

- Light weight

- Large specific surface area

- High Hardness

- Resistant to oxidation or reduction

- Resistant to high temperature

Ceramic Foam Applications

Unlike asbestos and other ceramic fibers, ceramic foam is completely harmless and is the best in insulation materials. Its high strength and hardness also make it useful as a structural material for low-stress applications. Ceramic foam has also been increasingly used in evolving electronic applications, including electrodes, solid oxide fuel cells and battery supports. By separating the pumped coolant from the circuit itself, ceramic foam can also be used as a cooling component for electronic devices.

ACM Ceramic Product Categories

Your Ceramic Foam Supplier

Advanced Ceramic Materials (ACM) is a leading supplier of ceramic foam products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us with any questions about aluminum oxide, boron nitride, zirconium oxide or other ceramic materials that are not listed on the website.