BN1809 Hot Pressed Boron Nitride Composite BN-AlN Ceramic

- Catalog No. BN1809

- Material BN+AlN

- Purity >99%

- Density 2.5-2.6 g/cm3

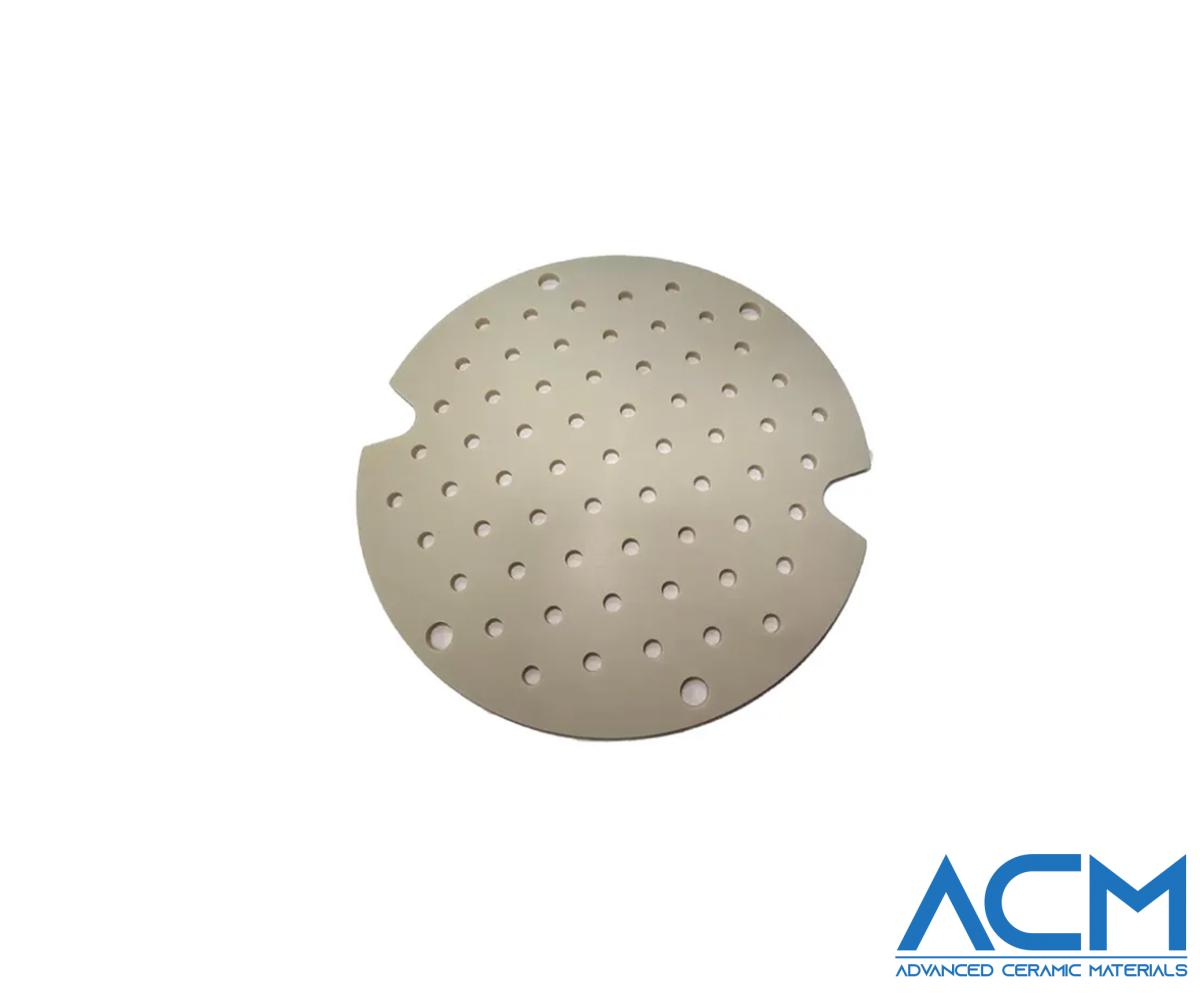

- Shape Customized

Datasheet

Inquiry

BN1809 Hot Pressed Boron Nitride Composite BN-AlN Ceramic

Composite BN-AlN Ceramic Description

Boron Nitride is a kind of advanced synthesis ceramic that was sintered at a high temperature and high pressure by BN powder. It has many excellent properties including high-temperature resistance, high thermal conductivity, easy machining, and good lubricity, making BN an outstanding material.

Boron nitride composite BN-AlN ceramic is manufactured by a transitional plastic phase process. The relative density of the hot-pressed composite ceramic decreases as the boron nitride content increases, but 30% of the boron nitride can be obtained in more than 99% of the aluminum nitride. Though materials such as quartz are not available in high-temperature gas atmospheres, boron nitride-aluminum nitride composite ceramic gears provide reliable drive performance.

High hardness, excellent wear resistance

High mechanical strength, high thermal conductivity

Provide a reliable driving force for gears

Composite Ceramic BN-AlN Specifications

| Grade | BN-AlN |

| Compositions | BN+AIN |

| Binder | AlBO3 |

| Density | 2.5-2.6 g/cm3 |

| 25°C Volume Resistivity | >1014 Ω·cm |

| Max. Service Temp.(°C) | 900 (Oxygen) |

| 2100 (Inert Gas) | |

| 1900 (High Vacuum) | |

| Flexural Strength | 130 Mpa |

| Compressive Strength | 250 Mpa |

| Coefficient of Thermal Expansion (25-1000°C) | 4.5 10-6/K |

| Thermal Conductivity | 60 W/mK |

Composite BN-AlN Ceramic Applications

Insulation

Semiconductor equipment components

Molded glass fixture material

Used as bearings and gears

Packaging

Our Boron Nitride BN-AlN Ceramic is always carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.

Request a Quote

-

Attachment (Optional)

No file chosen