ZSBN Nozzles Used in Molten Metal Atomization

ZSBN ceramic is widely applied to molten metal. In this article, we'll explain why ZSBN nozzles are preferred in Molten Metal Atomization.

What is Molten Metal Atomization?

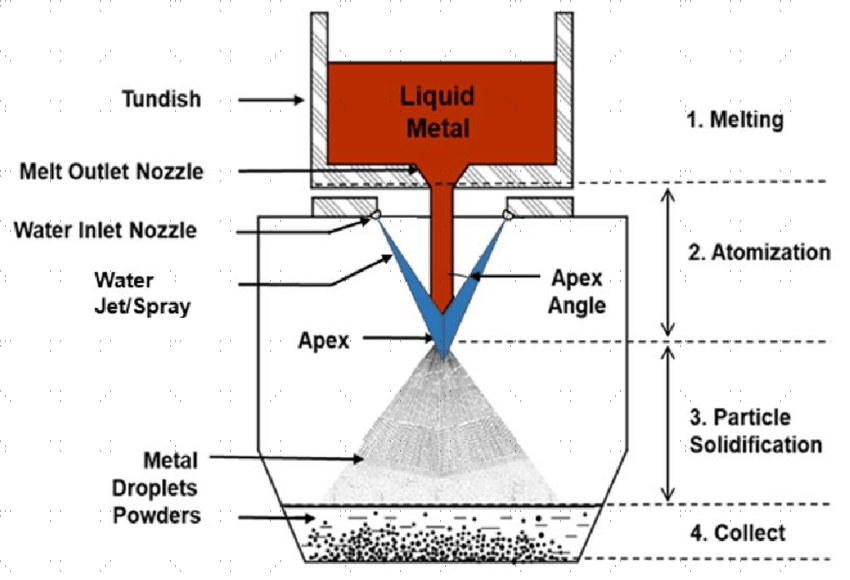

Atomization is the process of transforming material in solid or liquid form to its free gaseous state, which is commonly used in the molten metal industry to make fine metal powders from aluminum, iron, stainless steel, and super-alloys. The Molten metal atomization process can be divided into three steps.

- First, pour the melted metal down a ZSBN nozzle.

- Then, disperse the metal liquid with high-pressure water or gas jets.

- Finally, collect high-quality metal powder at the bottom, and use it for 3D printing and other crucial sectors.

Here, we explore the methods and devices like ZSBN nozzles used for metal atomization in this article. Further reading: 3D Printing Powder: What is it & How is it Used?

Types of Atomization

There are a variety of atomization methods including water atomization (WA), gas atomization (GA), electrode induction melting gas atomization (EIGA), and plasma atomization (PA). We offer a further explanation here.

1. Water Atomization (WA)

Water atomization is a dominant means to produce metal powder, especially ferrous metals. It accounts for 60% to 70% of iron powder production around the world. And a large number of copper, nickel, stainless steel, and soft magnetic powders are produced through water atomization. Water atomization is also quite popular in the powder metallurgy industry for its relatively lower cost. Compared with gas and other jet materials, it costs less energy and achieves higher productivity. However, water atomization doesn’t work when it comes to reactive metals and alloys. So gas atomization and other atomizing ways are created.

Asgarian, Ali & Wu, Cheng-Tse & Li, Donghui & Bussmann, Markus & Chattopadhyay, Kinnor & Lemieux, Sylvain & Girard, Bruno & Lavallee, Francois & Paserin, Vlad. (2018). Experimental and Computational Analysis of a Water Spray; Application to Molten Metal Atomization.

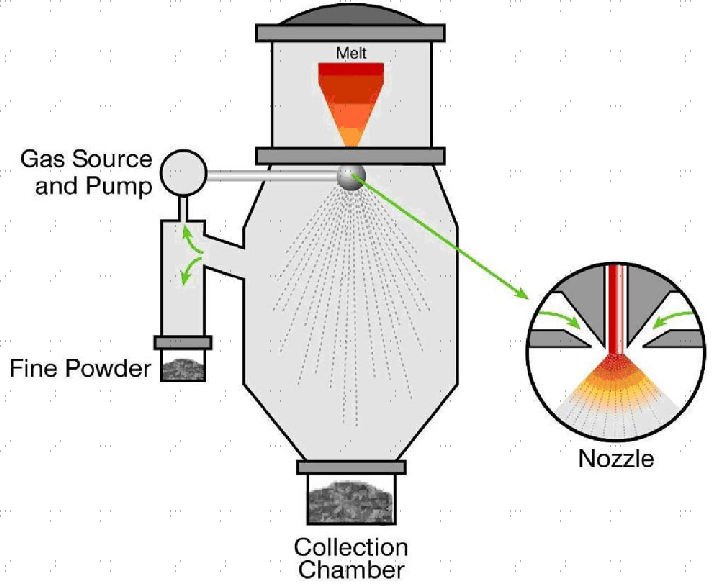

2. Gas Atomization (GA)

Gas atomization differs from WA in many aspects. Water atomization uses water jets, while gas atomization employs high-velocity gas to separate the liquid metal. WA is largely affected by the medium’s pressure, yet GA is not. The gas atomization is also applied to a wider range of materials. Namely, both GA and WA could be used for "confined" and "free-fall" nozzles, but only GA could be applied to "internal mixing" nozzles. Because of desirable the features mentioned above, gas atomization is widely used in zinc, aluminum, and copper alloy powder metallurgy.

Matsagopane, Gaamangwe & Olakanmi, Eyitayo & Els-Botes, A.. (2019). Conceptual Design Framework for Setting Up Aluminum Alloy Powder Production System for Selective Laser Melting (SLM) Process. JOM. 71. 10.1007/s11837-019-03431-w.

Requirements for Nozzles in the Atomization Process

There are lots of devices designed for the atomization process. First of all, a high vacuum or a low-pressure atmosphere is required. Jet materials such as water or gas are quite essential as well. Most importantly, the atomization process couldn’t go well without well-designed nozzles because broken or blocked nozzles can disrupt the powder production process. So a nozzle must meet the following requirements.

- High Hardness: The atomization process requires tough materials to make nozzles so that there won’t be any cracks.

- High Thermal Shock Stability: Strong materials are used to ensure perfect performance under high temperatures.

In short, strong refractory materials with high-temperature shock resistance are needed for the molten metal atomization process.

Why is ZSBN Suitable as A Metal Atomizing Nozzle?

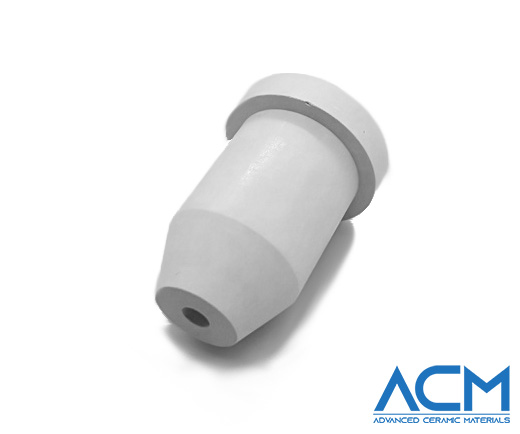

ZSBN ceramic is a composite material mixing boron nitride with silicon carbide and zirconia, and it is perfectly suited for molten metal sectors for its hardness and stability. Here are its excellent properties:

- High Strength: The union has remarkable strength because boron nitride has hexagonal layers, and the bond between boron and nitrogen is rather strong.

- Great Thermal Performance: This ceramic has a high melting point and high thermal shock resistance, so the ZSBN ceramic could remain solid and not break under thermal stresses.

- Other Strengths: It is easily machinable, and there is less clogging in the atomizer using ZSBN nozzles.

ZSBN Nozzles

ZSBN Nozzles VS Zirconia Nozzles

Zirconia used to be nozzle materials. Nevertheless, atomizers with zirconia nozzles frequently clog and could not produce fine particles. More clogging means more nozzle replacement, and the efficiency of the atomization process would be reduced, which brings about higher costs and other problems. So here come ZSBN nozzles. They do not have these problems for their properties mentioned above. Additionally, they do not need long-tome preheating and have a higher yield relatively (up to 30%).

Conclusion

ZSBN ceramic is an ideal option for nozzle-making for molten metal atomization since they have impressive strength and remarkably stable thermal performance. Hope that you have a better understanding of metal atomization and ZSBN nozzles after reading this article. Check our website for more information. Advanced Ceramic Materials (ACM) provides many more ZSBN ceramic products.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments