Case Study: Why 95% Alumina Beats 99% in Thermal Cycling

Introduction

This case study examines a client’s initial request for 99% alumina (Al₂O₃) in a high-temperature application reaching 1600 °C, with rapid thermal cycling at 200 °C per hour. While the request was based on the common assumption that higher purity ensures better thermal performance, a closer review of the operating conditions suggested an alternative. We recommended 95% alumina—a more thermally resilient and cost-effective option under these specific parameters.

Background

The client required ceramic components—specifically heater holders—capable of withstanding up to 1600 °C, with aggressive heating and cooling cycles at ±200 °C per hour. The original material request was 99% alumina, based on its known thermal stability, chemical inertness, and mechanical strength.

However, high-purity aluminum oxide may not always be the most suitable choice for fast temperature cycling. At extreme rates of expansion and contraction, ultra-pure ceramics can exhibit higher brittleness and reduced thermal shock tolerance, increasing the risk of cracking.

Problem Overview

The root assumption driving the client requests that higher purity equates to higher performance. While true in some static high-temperature applications, this does not always hold under dynamic, high-rate thermal cycling.

Thermal shock resistance is strongly influenced not only by maximum temperature but also by thermal expansion behavior and internal microstructure. In this case, rapid temperature shifts can induce thermal stress fractures in 99% alumina. The higher cost of this grade also raised questions about return on investment, especially if durability is compromised.

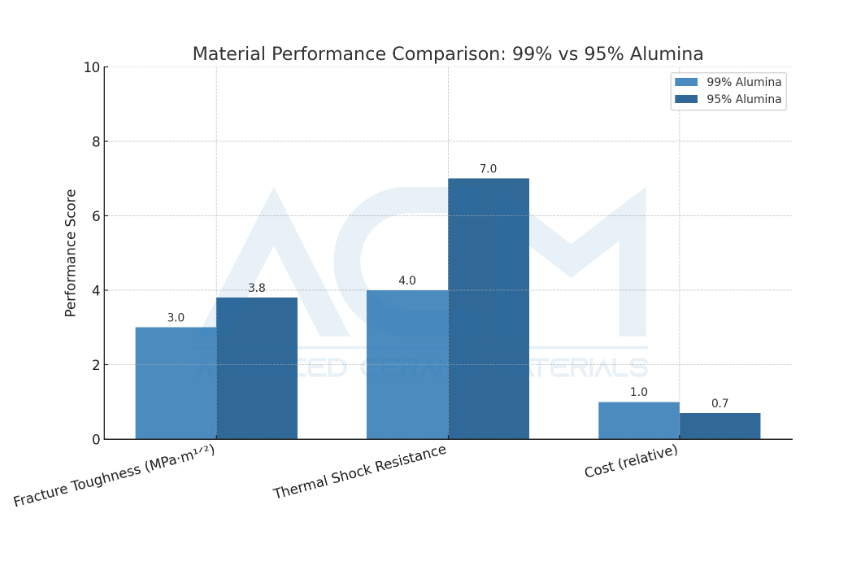

Comparative Analysis: 99% vs 95% Alumina

Option 1: 99% Aluminum oxide (Customer’s Original Specification)

Advantages

-

Excellent high-temperature performance (1600–1700 °C)

-

High density (3.85–3.90 g/cm³)

-

Good dielectric strength and chemical stability

Limitations

-

More sensitive to thermal gradients due to lack of grain-boundary dopants

-

Higher sintering temperature increases production cost

-

Higher material cost, not always justified under thermal cycling stress

Option 2: 95% Aluminum oxide (Recommended Alternative)

Advantages

-

Adequate for temperatures up to 1600 °C

-

Microstructure includes small amounts of dopants or secondary phases that enhance thermal shock resistance

-

Better tolerance to rapid heating and cooling cycles

-

More cost-efficient in both material and processing

Limitations

-

Slightly lower chemical purity and dielectric strength

-

May not meet requirements in ultra-clean or ultra-high frequency environments

Based on thermal cycling demands and cost considerations, 95% alumina offers a more balanced solution for the intended operating conditions.

Recommended Solution

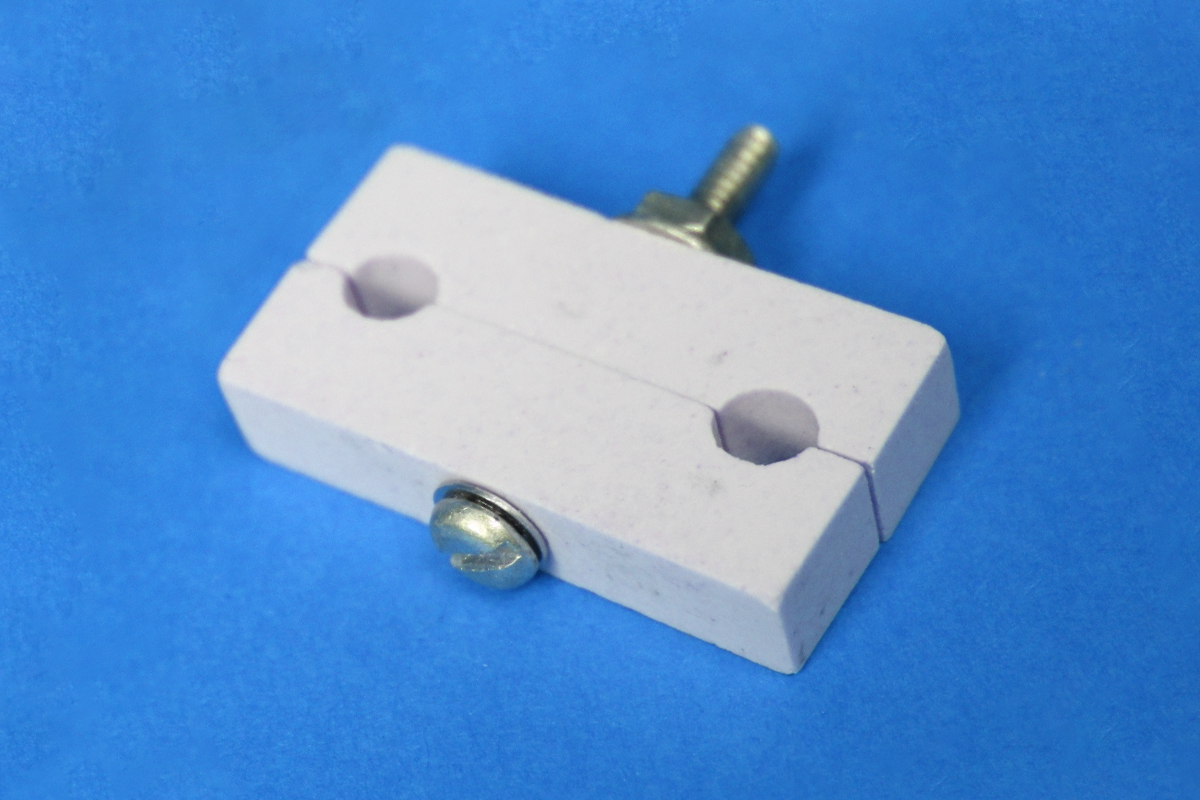

Advanced Ceramic Materials advised the client to shift from 99% to 95% alumina for the heater holder component. While 99% alumina is often considered the benchmark for high-temperature applications, the client's actual use case involves thermal shock exposure that favors a slightly lower-purity, more robust ceramic.

Senior Consultant Lisa Ross notes:

“After reviewing the temperature profile and cycling rate, we determined that 95% alumina offers a more stable response under stress. Its grain structure tolerates expansion mismatches better, reducing the risk of thermal cracking while still meeting the thermal limit.”

This recommendation not only aligns with performance requirements but also significantly reduces material costs without compromising operational safety or longevity.

Anticipated Results and Client Impact

-

Performance Assurance

The 95% alumina holder is expected to maintain structural integrity at 1600 °C and tolerate the 200 °C/hr ramp rates, minimizing downtime due to component failure. -

Cost Efficiency

The lower material and processing cost of 95% alumina delivers direct financial savings for the client, especially for batch production. -

Expertise and Trust

By providing a recommendation that challenges initial assumptions with solid technical reasoning, ACM reinforced its position as a trusted supplier and materials partner.

Implementation and Follow-Up

We recommend proceeding with 95% alumina samples for prototype validation, using the client’s technical drawings and operational data.

Advanced Ceramic Materials (ACM) will provide ongoing engineering support, including thermal stress simulations and mechanical testing, to ensure that the material performs reliably under real-world conditions.

Future discussions may explore additional optimization opportunities, such as glaze coatings or alternative sintering profiles, depending on evolving application demands.

Conclusion

This case highlights the importance of aligning material specifications with actual service conditions—not just relying on purity as a proxy for performance. In environments where thermal cycling is severe, slight reductions in purity can yield gains in reliability and cost.

By recommending 95% alumina, Advanced Ceramic Materials (ACM) delivered a solution that outperformed the original spec under dynamic thermal stress, while also improving cost-efficiency. This approach underscores our role not just as a materials supplier, but as a strategic advisor in advanced ceramic applications.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments