Thermal Management in Power Electronics with Hexagonal Boron Nitride

Introduction

A global manufacturer of silicon carbide (SiC) power modules faced repeated failures in thermal interface performance under high-temperature, high-voltage operation. Modules used in electric vehicle inverters and industrial drives regularly exceeded 300 °C, exposing weaknesses in conventional interface materials.

Advanced Ceramic Materials (ACM) recommended using high-purity Hexagonal Boron Nitride (h-BN) instead, because h-BN combines thermal conductivity with electrical insulation, stable up to 900 °C in air.

Background

The client’s power modules required reliable heat transfer and dielectric protection between SiC devices and copper heat spreaders. Key conditions included:

-

Continuous operation above 300 °C

-

Electrical insulation beyond 3,000 V

-

Compact module design with limited space for interface layers

-

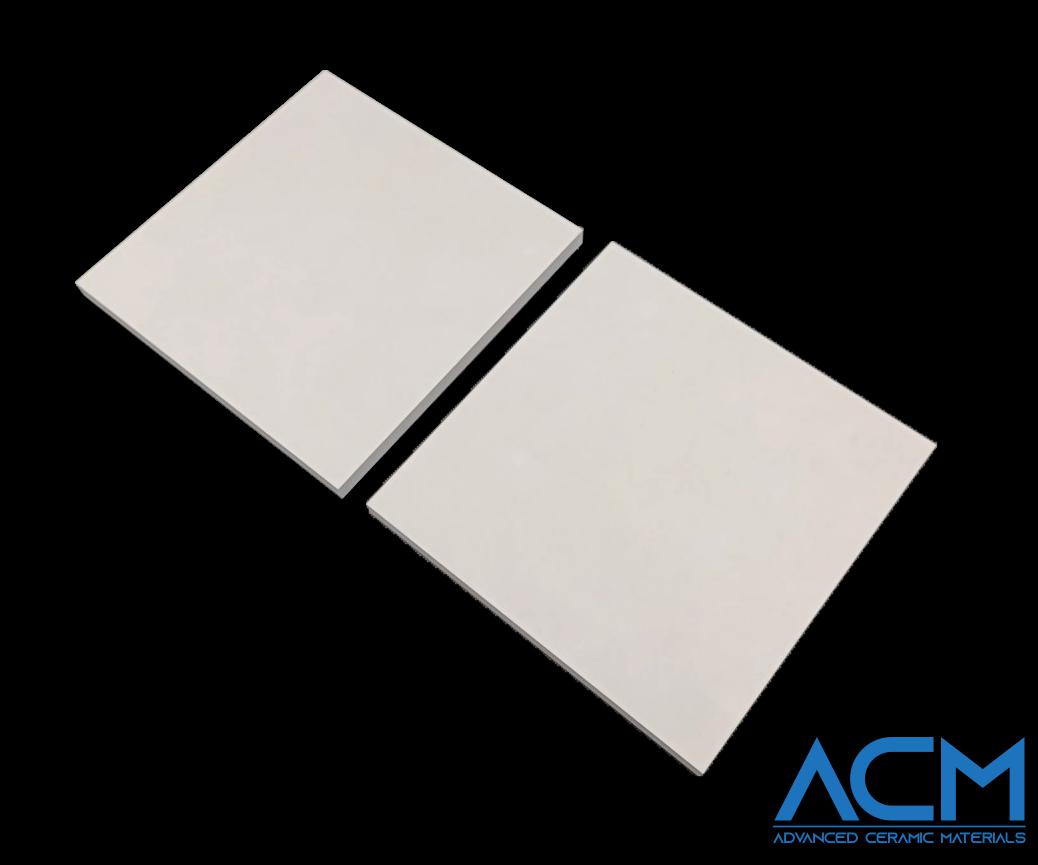

Sheet supply in 50 mm × 50 mm × 1 mm, with flatness and tight dimensional control

Previously used materials broke down under these demands. Symptoms included thermal degradation, dielectric failure, ceramic substrate warping, and inefficient heat spreading—especially under rapid load cycles.

Problem Overview

The failure stemmed from using polymer-based or low-grade ceramic thermal interface materials, which weren’t designed for prolonged exposure to extreme temperatures and voltages. Issues observed:

-

Sharp decline in thermal conductivity above 250 °C

-

Dielectric breakdown at high voltage

-

Poor dimensional stability leading to mechanical stress

-

Hotspot formation and uneven heat flow

The engineering team needed a material with both high thermal conductivity and electrical resistivity, without sacrificing mechanical stability or process compatibility.

Comparative Analysis: Conventional TIMs vs. ACM Grade-A h-BN

Option 1: Conventional Thermal Interface Materials

Advantages

-

Easy to apply and integrate

-

Low initial material cost

Limitations

-

Thermal conductivity degrades at high temperatures

-

Low dielectric strength beyond 3 kV

-

Breakdown or delamination above 250–300 °C

-

Incompatible with high-voltage SiC systems

Option 2: ACM Grade-A HBN (Recommended Alternative)

Advantages

-

Thermal conductivity: ~35 W/m·K (in-plane)

-

Electrical resistivity: >10¹³ Ω·cm

-

Dielectric strength: >3.5 kV/mm

-

Temperature stability: up to 900 °C in air, 1800 °C in inert gas

-

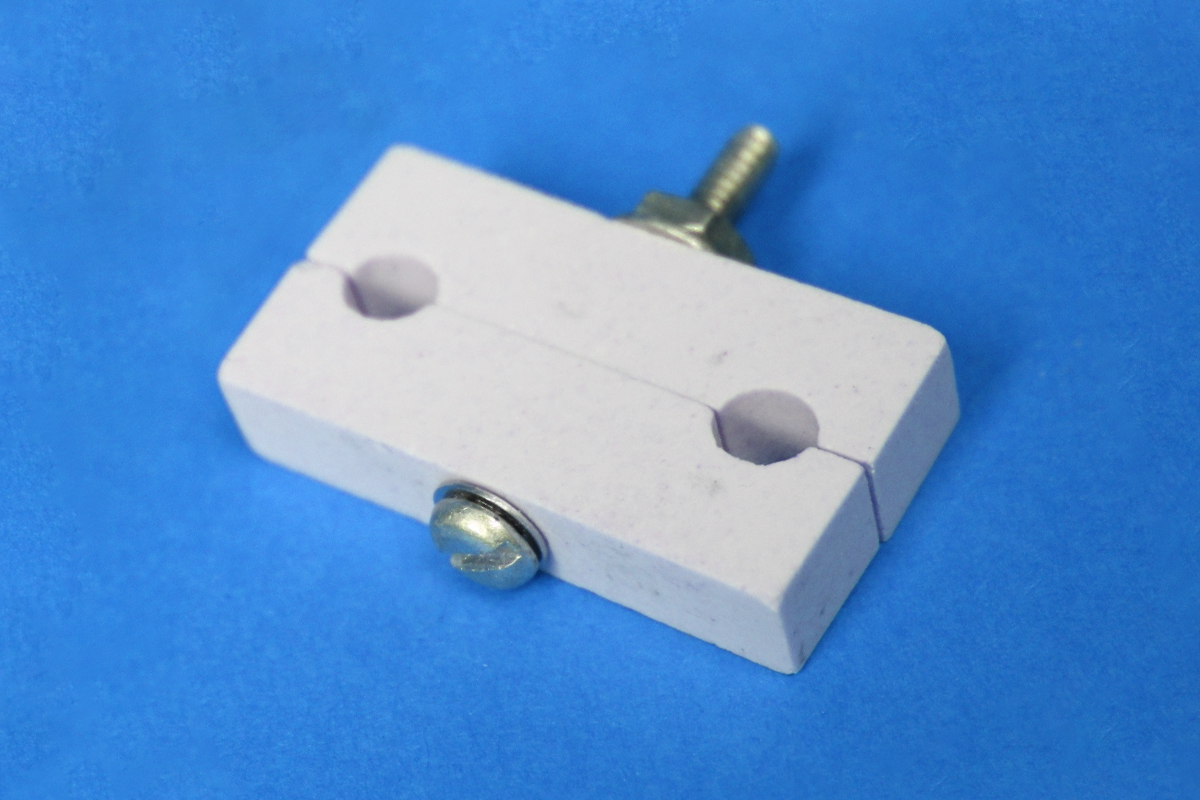

Excellent machinability for tight tolerances

-

Supplied in vacuum-sealed, flat sheets (±0.02 mm flatness)

Limitations

-

Slightly higher material cost

-

Brittle compared to polymer-based TIMs (requires careful handling)

ACM’s Grade-A h-BN provides a unique blend of thermal conductivity and dielectric integrity that directly matches the operational demands of modern SiC power systems.

Recommended Solution

ACM advised transitioning from the existing thermal interface materials to Grade-A Hexagonal Boron Nitride sheets, specifically engineered for high-temperature, high-voltage environments.

Materials Engineer Lisa Ross from ACM explains:

“We looked at the full application envelope—thermal, mechanical, electrical. h-BN offered the most stable profile under all three. Especially under repeated cycling between 25 °C and 300 °C, it maintained structural integrity and electrical insulation far better than conventional options.”

The client adopted h-BN as a dielectric thermal interface layer between SiC chips and copper heat spreaders.

Anticipated Results and Client Impact

Performance Assurance

-

40% increase in thermal dissipation efficiency

-

20 °C reduction in peak hotspot temperatures

-

Zero dielectric breakdown after 1,000 thermal cycles

-

Maintained flatness and bonding integrity across assemblies

Efficiency

-

Reduced rework and material replacement

-

Faster integration thanks to CNC machinability

-

Lower risk of field failures

Trust and Expansion

After successful implementation, the client expanded testing of h-BN to additional thermal-critical components, including coating trials and paste applications.

Implementation and Follow-Up

ACM provided full support during integration:

-

CNC machining based on module drawings

-

Thermal simulations to verify long-term stability

-

Packaging designed for moisture-sensitive logistics

Follow-up phases include trials with thinner sheets and hybrid ceramic stacks for improved space efficiency.

Conclusion

Purity alone doesn’t guarantee performance—especially under real-world thermal cycling. By shifting to high-purity h-BN, the client gained not just higher heat dissipation and electrical reliability, but also production and integration advantages.

Advanced Ceramic Materials delivered more than a material—we delivered a solution engineered for the demands of modern power electronics.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments