Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity

Introduction

Many people think of ceramics as the material used for coffee mugs or porcelain tiles. They assume that ceramics always keep heat in, acting as insulators. While this is partly true, it is a big simplification. In fact, technical ceramics cover a wide range of thermal conductivities. Their ability to either hold heat or let it pass through can differ by more than 200 times. This wide range makes ceramics useful in many applications, from handling hot engine temperatures to keeping electronic circuits cool.

Understanding Ceramics: More Than Just Insulators

One important point to remember is that the ability to insulate against electricity and to insulate against heat are two different things. With ceramics, these properties can be separated. This means engineers can pick a ceramic that stops electricity from flowing but still lets heat escape. This kind of mix is not usually available in metals or plastics. Such materials are very useful when building electronic circuits, where parts need to be electrically separated yet still get rid of excess heat quickly.

On the flip side, it is much trickier to make a ceramic that conducts electricity but stops heat. Sometimes, this effect is achieved by applying a special ceramic coating on a metal part.

The Insulators: Heat In

At one end of the spectrum, some ceramics are designed to stop heat from moving. These ceramics work hard by trapping heat, which is useful when you want to keep warmth inside a furnace or prevent heat from reaching delicate components.

Certain silicates like Cordierite, Steatite, and Porcelain, usually fall between 2 and 4 Watts per meter Kelvin. Zirconia-based ceramics, which are prized for their strength, have values around 3 Watts per meter Kelvin. An improved version, alumina-toughened zirconia, carries about 6 Watts per meter Kelvin. In practical settings, these materials are found in high-temperature furnaces, thermal barriers in jet engines, and other systems where keeping heat in is crucial for safe and efficient operation.

The Conductors: Heat Flow

On the other side, some ceramics are surprisingly good at conducting heat. These ceramics help take heat away from sensitive parts, like those in electronic devices.

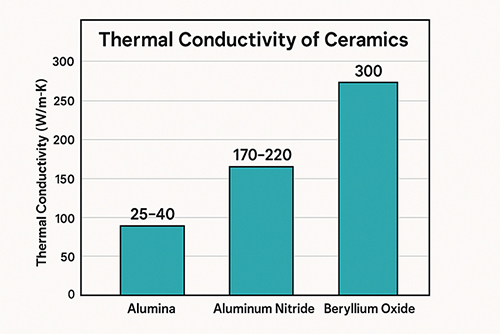

For example, alumina-based ceramics can carry heat with values from around 25 to 40 Watts per meter Kelvin. Aluminium Nitride typically shows thermal conductivities between 170 and 220 Watts per meter Kelvin, making it a popular choice for high-power electronics that need to get rid of heat fast. Beryllium Oxide goes even higher, reaching around 300 Watts per meter Kelvin.

However, a word of caution: Beryllium Oxide in its powder form must be handled with great care because it can be harmful if not processed in safe, controlled settings. These ceramics are often chosen for tasks like dissipating heat in phones, computer devices, and even in parts of aircraft.

The Science Behind the Variation

Why is there so much difference in heat conductivity? It is because of the way heat moves in non-metallic solids. In ceramics, heat is conducted mainly through vibrations in the lattice, or minute movements in the crystalline structure. When the crystalline structure is simple and smooth, heat flows more smoothly. But with impurities or a complex structure, these vibrations get scattered. This scattering lowers the thermal conduction of the material and, in most cases, allows it to act as an insulator.

Selecting the Right Material for Your Needs

Selecting a ceramic for any application is more than just heat-handling capability. Several other things are involved:

- Temperature Range: Plastics or metals will generally not function at extreme high or extreme low temperatures. Ceramics are best under these conditions.

- Surrounding Environment: If the material is to be employed in a reactive or corrosive environment, a ceramic like alumina or zirconia would be good because it is inert.

- Mechanical Strength: There are some applications where the material must withstand physical stress. Ceramics like zirconia-toughened ceramics offer strength along with thermal properties.

- Rapid Temperature Changes: When temperature is not allowed to change slowly, materials with high resistance to cracking due to low thermal expansion are best.

In everyday life, one can see ceramics in action in many mundane applications. High-power electronics, such as those of mobile phones and games, often use substrates of Aluminium Nitride to dissipate heat from components. In aerospace technology, components from satellite systems to engine parts use different ceramics to conduct heat effectively while resisting adverse environments.

Expertise in Action and a Trusted Partner

Handling these various properties and making the right material choices require a seasoned hand and plenty of experience. Working closely with experts from both academic and industry fields is key to success. I remember many years of working on engines and electronics, where the proper choice of ceramic not only solved a problem but also improved performance and safety.

Today, a reliable partner in supplying these advanced ceramic materials is Advanced Ceramic Materials (ACM). Their focus is on providing tailored solutions that help engineers from the design stage all the way through production. With MIT-level expertise and a practical mindset gained from countless real-world applications, ACM stands by its promise to guide clients in selecting the best ceramic materials for their specific needs.

Conclusion

Ceramics offer a broad range of thermal conductivities, from materials that keep heat trapped to those that quickly carry it away. This unique spread gives engineers many options when designing systems that must operate under extreme conditions or when delicate electronics need cooling without electrical interference. By understanding the specific behavior of these materials and considering factors like temperature, environment, and mechanical strength, professionals can choose the right ceramic for their projects.

With years of hands-on experience and academic insight, I can say that ceramics are not just simple materials but are key players in managing heat in many of our modern devices. For those who need high-quality materials and expert guidance, Advanced Ceramic Materials (ACM) provides a trusted source in this specialized field. Contact us for more information.

Read more: Top 10 Ceramic Materials with the Highest Thermal Conductivity

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments