Pyrolytic Boron Nitride (PBN)

Pyrolytic Boron Nitride (PBN) is a kind of boron nitride ceramic prepared by high-temperature pyrolysis reaction by chemical vapor deposition. This process involves the reaction of ammonia and boron halide under elevated temperatures and high vacuum conditions. PBN offers versatility in its deposition, allowing for the creation of sheet material or direct production of final products like tubes, rings, or thin-walled containers. In contrast to conventional hot-pressed boron nitride (BN), PBN eliminates the need for a standard hot-press sintering process and does not require the addition of any sintering agent.

One of the most notable aspects of Pyrolytic Boron Nitride is its exceptional properties, making it a highly sought-after material in various applications. Its characteristics include extreme purity, excellent oxide resistance, robust thermal shock resistance, high insulation resistance, and non-reactivity to most other compounds. Moreover, PBN demonstrates remarkable resilience in withstanding high temperatures. These properties collectively position Pyrolytic Boron Nitride as a valuable material with wide-ranging capabilities, contributing to its prominence in advanced technological and industrial applications.

More Info About Pyrolytic Boron Nitride

Products | Structures | Specification | Applications | Video | FAQs | Product Brochure

Pyrolytic Boron Nitride Structures

Pyrolytic boron nitride (PBN) exhibits unique structures that stem from its distinct preparation process. As a ceramic material, PBN is crafted through high-temperature pyrolysis reaction using chemical vapor deposition. This results in a structure that differs from conventional boron nitride ceramics like hot-pressed boron nitride (BN). Unlike the latter, PBN does not require a conventional hot-press sintering process, showcasing a structural independence that contributes to its versatility.

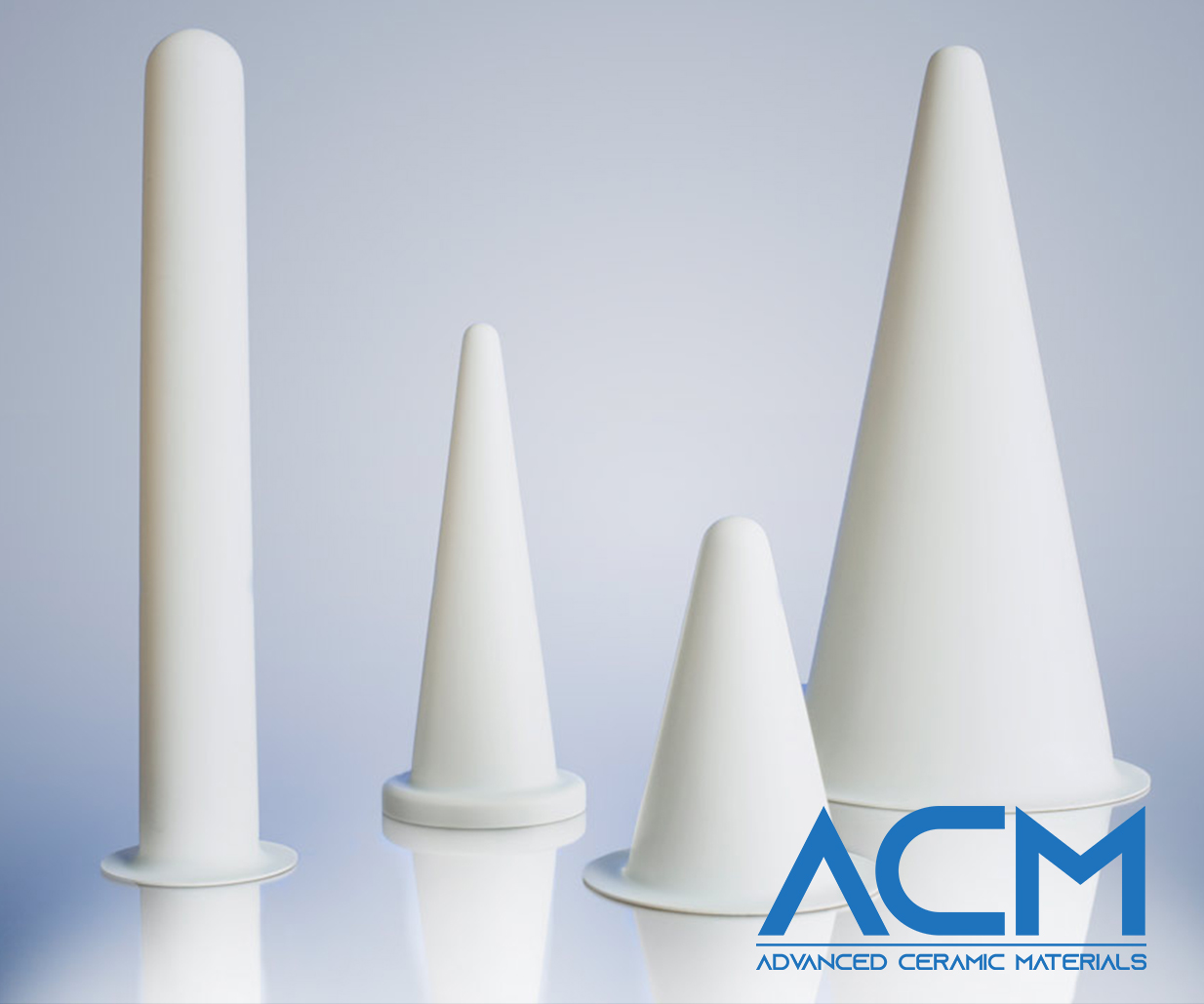

The structure of Pyrolytic Boron Nitride is notable for its purity and uniformity, as it can be deposited in various forms such as sheets, or directly as final products like tubes, rings, and thin-walled containers. The high-temperature and high-vacuum conditions during the deposition process contribute to the development of these well-defined structures. This structural precision, combined with the absence of sintering agents, underscores PBN's unique position as an advanced material with tailored structures, making it suitable for a range of applications across industries.

Pyrolytic Boron Nitride Specification

| Physical Properties | |

| Density | 1.95 - 2.22 g/cc |

| Mechanical Properties | |

| Tensile Strength, Ultimate (23°C) |

40.0 MPa |

| 103 MPa | |

| Modulus of Elasticity | 22.0 GPa |

| Flexural Strength | 80.0 MPa |

| Compressive Strength | 234 MPa |

| Poissons Ratio | 0.25 |

| Shear Modulus | 8.80 GPa |

| Electrical Properties | |

| Electrical Resistivity | 1.00e+15 ohm-cm |

| Dielectric Constant | 3.4 |

| 5.2 | |

| Dielectric Strength | 200 kV/mm |

| Thermal Properties | |

| Thermal Conductivity | 2.00 W/m-K |

| 60.0 W/m-K | |

| Maximum Service Temperature, Air | 750 °C |

| Maximum Service Temperature, Inert | 2500 °C |

Pyrolytic Boron Nitride Applications

Pyrolytic Boron Nitride (PBN) ceramics boast a diverse range of applications, capitalizing on their unique properties such as high purity, chemical inertness, and exceptional thermal conductivity. This advanced material finds itself at the heart of technological and industrial advancements across various sectors:

Semiconductor Manufacturing:

- PBN Crucibles for Elemental Purification: Leveraging its high purity and chemical inertness, PBN crucibles play a pivotal role in elemental purification, ensuring semiconductor materials remain free from impurities.

- Crystal Growth Processes: PBN contributes to the meticulous process of crystal growth, facilitating the formation of high-quality crystals crucial for manufacturing reliable semiconductor devices.

- Next-Generation Compound Semiconductors: Particularly essential in the production of advanced compound semiconductors like Gallium Arsenide (GaAs) and Indium Phosphide (InP), PBN plays a key role in shaping the future of electronic components.

Aerospace and Aviation:

High-Temperature Stability: In aerospace and aviation applications, where extreme temperatures and harsh conditions are prevalent, PBN's stability becomes indispensable. Its ability to withstand high temperatures without compromising structural integrity makes it valuable in manufacturing components for aerospace exploration.

Electronics:

Advanced Electronic Devices: PBN components contribute to the development of high-performance electronic devices. Its excellent thermal management capabilities ensure efficient heat dissipation, enhancing the reliability and longevity of electronic components in demanding applications.

Chemical Industry:

Chemical Inertness in Processes: PBN's chemical inertness finds application in various chemical processes. PBN equipment and components can operate in environments with aggressive chemicals without undergoing degradation, making it a reliable choice in chemical industry applications.

Special Metallurgy:

Specialized Metallurgical Processes: Harnessing PBN's unique properties, industries engage in specialized metallurgical processes where resistance to chemical reactions and high temperatures is advantageous for specific alloying and refining procedures.

Medical Applications:

Chemically Inert Medical Equipment: PBN's chemical inertness is beneficial in the design and manufacturing of medical equipment and devices where maintaining a sterile and non-reactive environment is crucial. Applications include medical implants and laboratory equipment.

Read more: Uses of Pyrolytic Boron Nitride

ACM Ceramic Product Video

Your PBN Ceramics Supplier

Advanced Ceramic Materials is a leading supplier of pyrolytic boron nitride ceramic products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us with any questions about PBN or other ceramic materials that are not listed on the website.

Read more: What is Pyrolytic Boron Nitride (PBN)?

| Chemical Formula | PBN |

| Mechanical | |

| Density | 2.0-2.2 g/cm3 |

| Hardness | 4 Mohs |

| Modulus of Elasticity | 40 GPa |

| Flexural Strength | 85 Mpa |

| Compressive Strength | 200 MPa |

| Poisson's Ratio | 0.11 |

| Fracture Toughness | 1.5 MPa·m¹/² |

| Electrical | |

| Dielectric Strength | 56 kV/mm |

| Dielectric Constant | 4.0 (@ 1 MHz) |

| Volume Resistivity | >10¹³ ohm·cm |

| Thermal | |

| Coefficient of Thermal Expansion | 1.4 x 10-6 /°C |

| Thermal Conductivity | 60 W/m·K |

| Specific Heat | 0.8 J/g·K |

| Shock Resistance | - |

| Maximum Working Temperature | 1800 °C |