Zirconia Toughened Alumina (ZTA)

Zirconia Toughened Alumina (ZTA) is a composite material that uniquely combines the mechanical strength and wear resistance of zirconia and alumina, making it superior to traditional alumina ceramics. By incorporating 10-20% volume of ZrO2 into alumina, ZTA not only enhances the material's toughness and strength but also offers a cost-effective alternative to pure zirconia, addressing both performance and economic considerations. This adjustment in composition allows for the customization of ZTA's properties to specific needs, making it an ideal choice for a wide range of applications.

The key attributes of ZTA include exceptional mechanical strength, thermal resistance, corrosion resistance, and biocompatibility. These features make it highly suitable for demanding industrial uses and medical applications where durability and safety are paramount. The ability to tailor its properties through zirconia content optimization ensures that ZTA can meet diverse requirements, providing a versatile solution that outperforms conventional materials in both functionality and longevity.

More Info About Zirconia Toughened Alumina

Products | Structure | Specification | Applications | Video | FAQs

Zirconia Toughened Alumina Structure

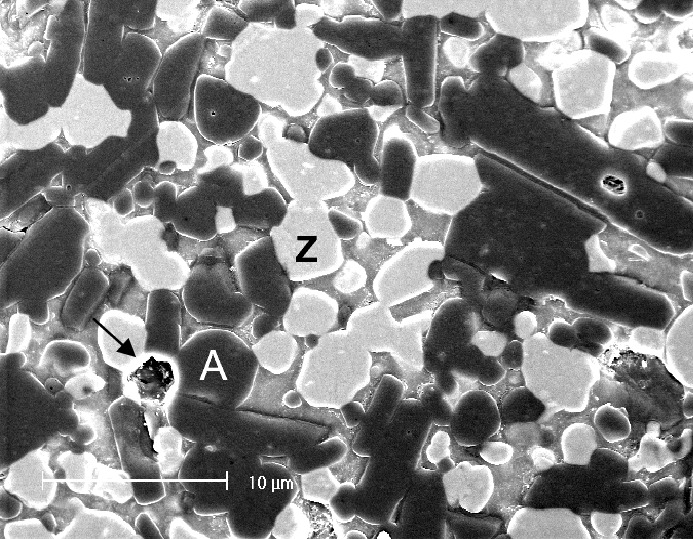

The microstructure of zirconia-toughened alumina (ZTA) slip-cast ceramic reveals a finely integrated composite material where alumina (A) grains and zirconia (Z) grains coexist, each contributing unique properties to enhance the overall performance of the ceramic. Alumina grains provide the structural backbone, offering high hardness and thermal stability, while the dispersed zirconia grains impart toughness and resistance to crack propagation. This strategic combination results in a ceramic that is not only stronger but also more durable than its individual constituents. The presence of pores, as indicated by arrows, is typical in slip-cast ceramics and can affect the material's density and mechanical properties. The control of pore size and distribution is crucial in optimizing the material's strength and reliability, making the microstructural examination a key aspect in the development and improvement of ZTA ceramics. This microstructural synergy between alumina and zirconia grains, along with the careful management of porosity, underscores the material's advanced engineering, tailored for applications requiring exceptional mechanical and thermal performance.

Microstructure of zirconia-toughened alumina slip-cast ceramic. A: alumina grains, Z: zirconia grains, Arrow indicates pore. Isabelle, Denry & Holloway, Julie. (2010). Ceramics for Dental Applications: A Review. Materials. 3. 10.3390/ma3010351.

Zirconia Toughened Alumina Specification

| Chemical Formula | Zr-Al2O3 |

| Density | 4.1-4.38 g/cm^3 |

| Hardness | 1750-2100 Knoop |

| Elasticity | 45-49 x 10^6 psi |

| Flexure Strength | 100-145 ksi |

| Poisson's Ratio | 0.26 |

| Fracture Toughness | 5-7 MPa m^1/2 |

| Coefficient of Thermal Expansion | 8.0-8.1 x 10^-6 1/C |

| Thermal Conductivity | 20.0-21.0 W/mK |

| Shock Resistance | 325 °C |

| Maximum Working Temperature | 1650 °C |

Zirconia Toughened Alumina Applications

Industrial Components

Where high strength and erosion resistance are paramount, Zirconia Toughened Alumina (ZTA) ceramics excel as the first choice for critical industrial components. This includes valve seals, sleeves, pump pistons, and spraying nozzles, which benefit from ZTA's unmatched durability and resistance to wear and harsh conditions. The material's robustness ensures longevity and reliability, making it indispensable in various industrial settings.

Manufacturing Industries

In the manufacturing sector, ZTA stands out for its application in cutting tools, thanks to its superior properties such as high hardness, wear resistance, chemical inertness at room temperature, and high hot hardness. Its rapture strength, moderate heat resistance, and compressive strength make ZTA superior to other cutting tool materials, enhancing productivity and efficiency in manufacturing processes.

Other Diverse Applications

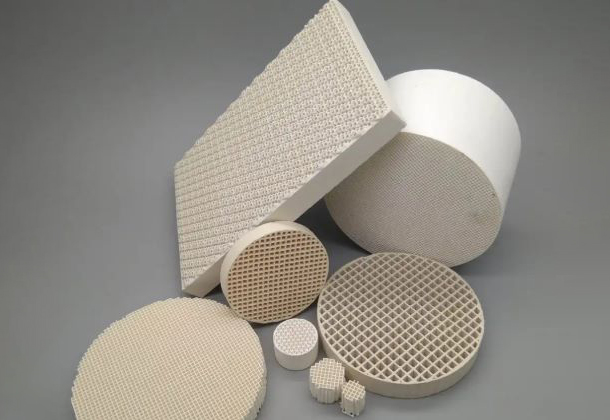

- Standoffs & Insulators: ZTA's electrical insulating properties make it ideal for standoffs and insulators, ensuring safety and reliability in electrical systems.

- Probe Bodies & Bushings: Its mechanical strength and stability under thermal stress are crucial for components like probe bodies and bushings.

- Fluid Delivery System Components: ZTA's chemical inertness and wear resistance are advantageous for fluid delivery systems, preventing contamination and ensuring component durability.

- Pump Position Sleeves & Instrumentation: In pump systems and instrumentation, ZTA's hardness and resistance to erosion protect critical moving parts and sensitive devices.

- Sensor Bulbs & Impellers: For applications requiring precise temperature measurements and fluid movement, ZTA provides the necessary durability and stability.

- Analytical Instrument Columns: In analytical instruments, ZTA's chemical stability and resistance to wear extend the life of columns and improve the reliability of analyses.

These headings highlight ZTA's wide-ranging applications, demonstrating its critical role in enhancing the performance and durability of components across various industries. From heavy-duty industrial use to precise analytical measurements, ZTA's unique combination of strength, resistance, and stability makes it an invaluable material in modern technology and industrial processes.

Read more: What is Zirconia Toughened Alumina?

ACM Ceramic Product Video

Your ZTA Ceramics Supplier

Advanced Ceramic Materials is a leading supplier of zirconia toughened alumina ceramic products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us with any questions about ZTA or other ceramic materials that are not listed on the website.

| Chemical Formula | ZrO2+ Al2O3 |

| Mechanical | |

| Density | 4.2-4.6 g/cm³ |

| Hardness | 12-14 GPa |

| Modulus of Elasticity | 300-350 GPa |

| Flexural Strength | 600-800 MPa |

| Compressive Strength | 2000-2500 MPa |

| Poisson's Ratio | 0.23-0.26 |

| Fracture Toughness | 6-8 MPa m½ |

| Electrical | |

| Dielectric Strength | 10-15 kV/mm |

| Dielectric Constant | 9-11 |

| Volume Resistivity | 10^14 Ω·m |

| Thermal | |

| Coefficient of Thermal Expansion | 8-10 x 10^-6 /°C |

| Thermal Conductivity | 25 W/(m*K) |

| Specific Heat | 0.75 J/g·K |

| Shock Resistance | - |

| Maximum Working Temperature | 1600 |