Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

Introduction

In many industrial processes, ceramic setters are used to sinter complex metal-organic compounds such as aluminum nitride, gallium nitride, and even graphene. These compounds find their way into diverse applications, with semiconductor production being one of the major ones. In semiconductor work, purity is essential, which means every part of the production line—from raw materials to the equipment itself—must meet strict standards. In this setting, hexagonal boron nitride emerges as an excellent material for ceramic setters.

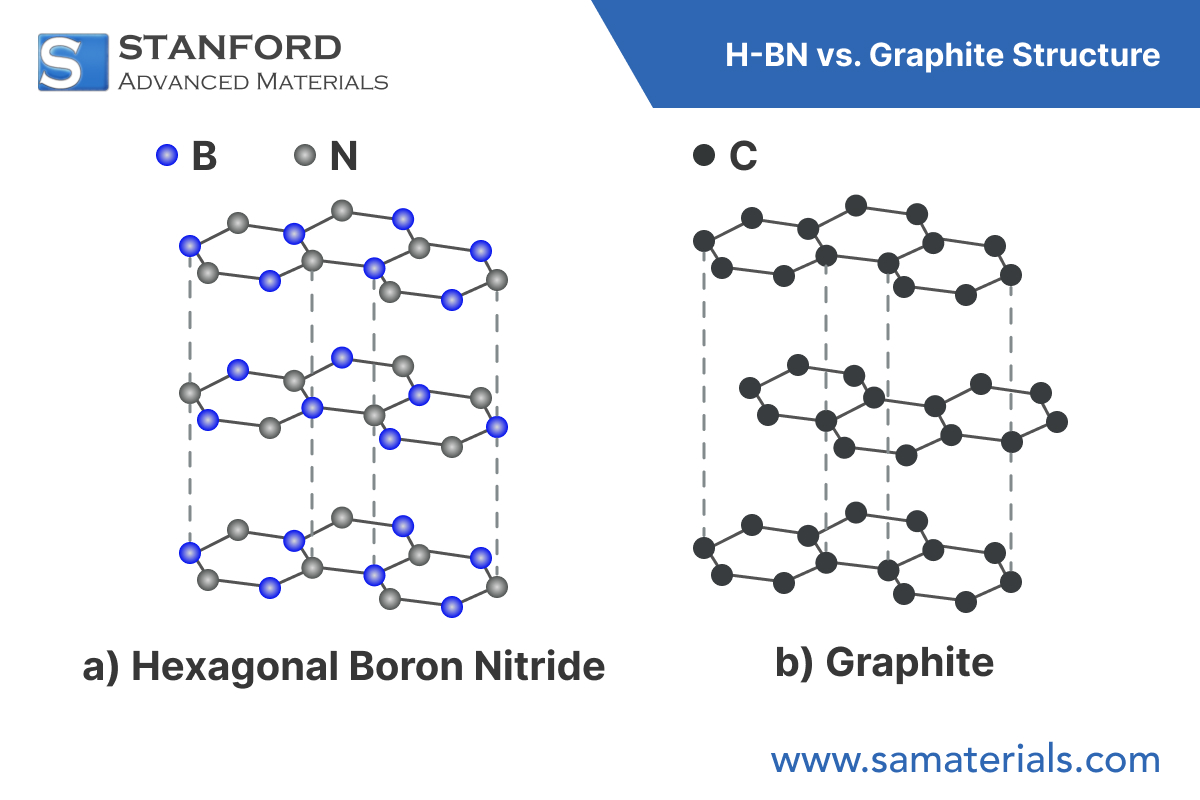

Unlike some materials that can degrade under demanding conditions, hexagonal boron nitride (HBN) offers a reliable option with its built-in stability and structure. Its unique honeycomb-like arrangement of boron and nitrogen atoms provides excellent electrical insulation and the capacity to handle temperatures as high as 2000°C. With these properties, HBN ceramic setters ensure that the underlying processes remain steady and uncontaminated even in the harsh environment of semiconductor production.

Advantages of Using Hexagonal Boron Nitride

The structure of hexagonal boron nitride is one of its key benefits. When you look at the atomic arrangement, you see a framework where boron and nitrogen atoms are tightly bound in layers that sit like a honeycomb. This kind of regular structure not only offers great physical strength but also means the material maintains its benefits under high heat. It is an electrical insulator and holds its form even under severe temperature changes. In everyday settings, you might see HBN used in items like furnaces, crucibles, and high-temperature liners. Its ability to resist corrosion, wear, and sudden thermal shifts makes it a trustworthy component in high-precision processes.

Image Credit: Stanford Advanced Materials

MOCVD Process and the Role of Ceramic Setters

Metal‐Organic Chemical Vapor Deposition (MOCVD) is a process that builds thin films by slowly depositing materials onto a substrate. This method is widely used to create layers for semiconductors, solar cells, and even materials used in bandgap and quantum dot applications. For this deposition to work properly, the environment needs to be very clean. Any unwanted reaction or impurity can lead to uneven layers or even defects. This is where HBN ceramic setters come in. They provide a stable platform that does not react with the organometallic chemicals used during deposition.

With HBN in place, the heating required to encourage crystal growth is more uniformly delivered across the substrate. In other words, it makes the overall process easier to control. Think of it like using the right tool on a workbench: when everything is stable and predictable, you get a finer result. In the fast-growing world of semiconductor technology, even small improvements in yield and purity can make a big difference.

High Temperature Stability

One key advantage of using HBN ceramic setters is their outstanding stability at high temperatures. In most MOCVD operations, temperatures often range from 900°C to 1000°C. At these high temperatures, many materials would start to show signs of wear or even undergo structural changes. However, HBN remains stable and retains its properties. This characteristic is critical. Because the material does not break down, it prevents any chance of contaminating the delicate thin films with degraded particles. The reliability of HBN at such high temperatures means that operators can maintain a clean and consistent process during the crucial phase of film deposition.

Chemical Inertness and Purity

Chemical inertness is another strong suit of hexagonal boron nitride. During the deposition process, different chemicals and vapors are present inside the reaction chamber. Any material that reacts with these chemicals could compromise the purity of the thin films. With HBN ceramic setters, you can be confident that the setter itself will not interfere. Its inert nature keeps the reaction chamber free of unwanted reactions, ensuring that the films remain pure and meet the demanding standards required for semiconductors. This benefit is similar to having a container that does not interact with its contents—it simply holds them without affecting their quality.

Improved Equipment Life with Lubricating Properties

Beyond thermal and chemical stability, HBN also offers a low coefficient of friction. This means that when it is used in ceramic setters, it helps reduce the wear on moving parts found in MOCVD equipment. Consider the importance of a smooth surface in any mechanical system; it not only ensures better performance but also extends the life of the equipment. In everyday terms, this is like using a well-oiled machine that runs quietly and steadily without extra maintenance. The lubricant-like properties of HBN help to maintain a uniform gas flow over the substrate, which in turn results in evenly deposited thin films. For industries that depend on nanometer-level precision, these small details add up to significant improvements in product reliability.

Systematic Benefits in Industrial Applications

Using HBN ceramic setters in high-temperature processes brings several system-wide benefits. First, the uniformity of heat transfer helped by HBN results in more consistent crystal growth. Second, the inertness of the material keeps the deposition environment free from contaminants that might otherwise spoil the film quality. Third, the low friction provided by the ceramic setters reduces wear on expensive MOCVD equipment, leading to lower overall maintenance costs. In practical scenarios across semiconductor manufacturing plants, these advantages combine to produce devices that are more reliable and meet the exacting standards of modern electronics.

Industries looking to maximize yield while keeping impurity levels low find that an HBN-based approach offers both the performance and the longevity needed for sustained operation. When every layer of a semiconductor must be just right, even a tiny improvement in uniformity or stability can have a large impact on the final product.

Conclusion

Hexagonal boron nitride ceramic setters offer many practical advantages for Metal‐Organic Chemical Vapor Deposition processes. Their high-temperature stability ensures that they remain robust during the demanding heating cycles common to thin film deposition. With chemical inertness, they keep the environment inside the deposition chamber clean and free from contaminants. And thanks to their low friction, they help extend the lifespan of expensive equipment by reducing wear.

The cumulative benefits of using HBN ceramic setters are clear: higher yield, improved purity, and a more reliable manufacturing process. In an industry where even small differences can lead to significant performance improvements, these ceramic setters provide a worthwhile upgrade.

For those who are interested in using hexagonal boron nitride ceramic setters to improve MOCVD performance, Advanced Ceramic Materials (ACM) offers dependable materials and expert support. Their commitment to high-quality supplies makes them a trusted source for companies aiming to boost both yield and purity in their production processes.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments