AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

The performance ceiling of an Electrostatic Chuck (ESC) is determined by its ceramic substrate. As semiconductor processes demand unprecedented wafer temperature uniformity and stability, traditional alumina (Al₂O₃) substrates are hitting fundamental material limits. This shift is driving ESC manufacturers to adopt Aluminum Nitride (AlN) ceramics.

Introduction: The Substrate is the Foundation

For ESC manufacturers, the ceramic substrate is not a passive component; it is the active platform that defines thermal fidelity, clamping reliability, and long-term stability. With process margins vanishing at advanced nodes, the industry can no longer tolerate the thermal gradients and wafer stress imposed by material limitations. The transition from alumina to aluminum nitride is not a matter of preference, but a response to the non-negotiable thermal and mechanical requirements of modern plasma etch, deposition, and lithography processes.

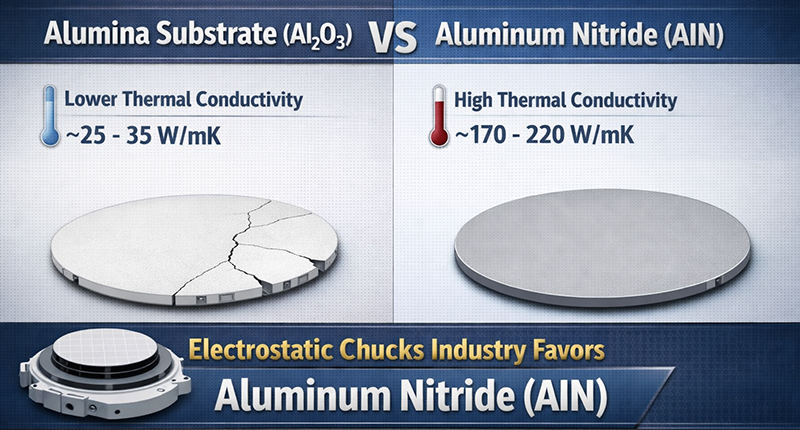

The Performance Gap: Alumina vs. Aluminum Nitride

ESC designers choose AlN because it solves critical problems that alumina cannot. The decision matrix is clear when comparing key properties:

| Property | Alumina (Al₂O₃) | Aluminum Nitride (AlN) | Implication for ESC Design & Performance |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 25 - 35 | 170 - 220 | This is the decisive factor. AlN's ~6x higher conductivity enables ESC designers to achieve wafer temperature uniformity of ±0.5°C or better on 300mm wafers, eliminating hot spots that cause process variation with Al₂O₃. |

| Coeff. of Thermal Expansion (CTE, ppm/K) | ~7 - 8 | ~4.5 | AlN's CTE is a near-perfect match to silicon wafer (~3 ppm/K). This allows ESC manufacturers to design chucks for thinner wafers and wider temperature ranges without inducing thermal stress or wafer bow, a critical advantage for warpage-sensitive processes. |

| Dielectric Strength & Volume Resistivity | Excellent | Excellent | Both materials provide the insulation and controlled resistivity needed for reliable electrostatic clamping (J-R or Coulombic). The choice depends on the specific resistivity target and stability required by the ESC design. |

| Mechanical Strength | High | Moderate to High | Alumina offers higher bend strength, but AlN's strength is more than sufficient for ESC applications when the substrate is properly designed and supported. |

Beyond the Blank: Critical Ceramic Substrate Capabilities for ESC Assembly

Supplying a polished AlN blank is only the first step. ESC manufacturers require a materials partner that can deliver substrates ready for high-yield integration. Key capabilities include:

-

Precision Metallization for Embedded Heaters & Electrodes: The ability to print, plate, or co-fire complex tungsten or molybdenum-based circuits with high adhesion and conductivity is paramount. At ACM, we specialize in thick-film and HTCC (High-Temperature Co-fired Ceramic) metallization that survives sintering and delivers consistent electrical performance.

-

Nanoscale Surface Finish & Flatness: The wafer-contact surface must be optically flat (TTV < 1 µm) with a controlled micro-roughness to optimize thermal transfer and prevent wafer sticking. We provide substrates with surface finishes (Ra) consistently below 10 nm, achieved through proprietary polishing techniques.

-

Demonstrated Bonding Integrity: The ceramic substrate must be reliably joined to a metal baseplate. We offer pre-brazed AlN-stainless steel assemblies or provide meticulously prepared surfaces for customer bonding, backed by shear strength and thermal cycle test data.

The Supplier Evaluation Checklist for ESC Builders

When sourcing AlN substrates, ESC manufacturers must look beyond a datasheet. Ask your ceramic supplier these five questions:

-

"What is the lot-to-lot variation in thermal conductivity for your AlN, and how is it verified?" (Consistency is key for predictable ESC performance.)

-

"Can you provide a full material characterization report, including dielectric properties (εᵣ, tan δ) at operational frequencies and temperatures?" (Ensures the material meets specific RF and thermal design needs.)

-

"What is your standard and guaranteed capability for surface flatness (TTV, Bow) and micro-roughness (Ra)?" (Directly impacts wafer contact and heat transfer.)

-

"What metallization options do you offer, and what are the typical adhesion strengths (e.g., via peel tests)?" (Critical for the lifetime of embedded heaters and electrodes.)

-

"Do you provide sub-assembly services, such as pre-metallization or brazing to specified baseplates?" (This can significantly reduce your integration risk and time-to-market.)

Conclusion

The switch to Aluminum Nitride is the most impactful decision an ESC manufacturer can make to meet the thermal control demands of 3nm nodes and beyond. This transition requires more than just a new material; it requires a partner with deep expertise in ceramic science, precision machining, and functional integration.

At Advanced Ceramic Materials (ACM), we provide the high-purity, high-thermal-conductivity AlN substrates and advanced metallization services that are the foundation of leading-edge E-Chucks. We partner with ESC manufacturers to turn material advantages into reliable, superior-performing products.

Ready to evaluate the AlN substrates that will define your next-generation ESC design?

Contact ACM today to receive our comprehensive datasheet, including detailed property tables, metallization options, and standard tolerances.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments

- Aluminum Oxide Ceramics: Properties and Applications