AC3225 Polished Alumina Substrate, Al2O3

- Catalog No. AC3225

- Material Al2O3

- Purity 96%, 99.5%

- Thickness 3.7g/cm3, 3.9g/cm3

Datasheet

Inquiry

AC3225 Polished Alumina Substrate, Al2O3

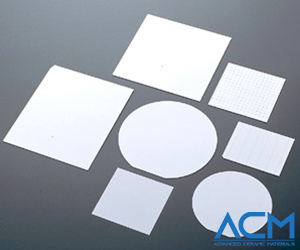

Polished Alumina Substrate Description

Polished Alumina Substrate features dimensional stability at high temperatures for multilayer thin-film technology. It mitigates the electrical disconnection in thin-film printed circuits and withstands the extreme natural condition of some sample solutions and variances in temperature.

Polished Alumina Substrate Specifications

| Product No. | A476T | A479 | A479H |

| Content % | 96 | 99.5 | 99.5 |

| Color | White | Ivory | Ivory |

| Density (g/cm3) | 3.7 | 3.9 | 3.9 |

| Size |

Max. 120mm x 120mm SQ Thickness: 0.25, 0.38, .0635mm |

||

| Thickness Tolerance |

±0.02mm (<3 square inches) ±0.05mm (≥3 square inches) |

||

| Substrate Thickness (mm) | 0.05-2.7 | 0.05-0.7 | 0.05-0.7 |

| Flatness (mm) | 0.05-0.6 | 0.05-0.4 | 0.05-0.4 |

| Surface Roughness (Mirror Polish) (mm) |

<Ra0.05 | <Ra0.02 | <Ra0.01 |

| Vickers Hardness HV9.807N (Gpa) | 13.7 | 15.7 | 15.7 |

| Flexural Strength (Mpa) | 350 | 370 | 370 |

| Young's Modulus of Elasticity | 320 | 370 | 370 |

| Thermal Conductivity (20℃) | 24 | 32 | 32 |

| Specific Heat Capacity (J/g·K) | 0.78 | ||

| Dielectric Strength (kV/mm) | 15 | ||

Polished Alumina Substrate Applications

To hold samples for spectroscopic measurement.

Packaging

Our Polished Alumina Substrate is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Request a Quote

-

Attachment (Optional)

No file chosen