Boron Nitride (BN)

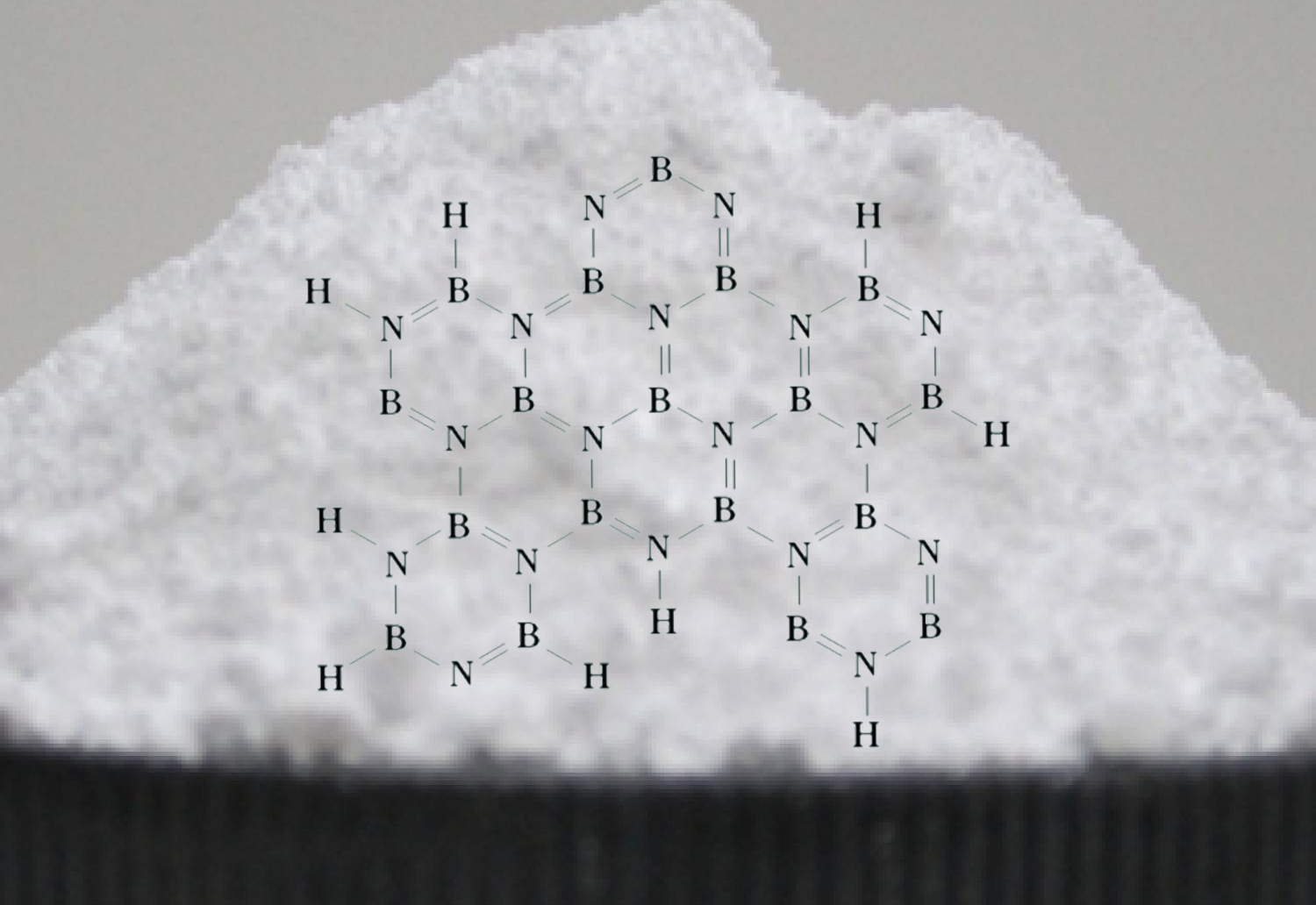

Boron Nitride (BN) encompasses diverse forms, including Hexagonal Boron Nitride (h-BN) and Pyrolytic Boron Nitride (PBN), making it an advanced synthetic ceramic material available in solid and powder forms, renowned for its exceptional properties. The microstructure of boron nitride makes it as an excellent electrical insulator with a higher oxidation temperature. Boasting high heat capacity, outstanding thermal conductivity, easy machinability, lubricity, low dielectric constant, and superior dielectric strength, Boron Nitride stands out as a versatile material.

In its solid form, Boron Nitride exhibits a hexagonal platy crystal structure, likened to "white graphene" or "inorganic graphite." These materials offer high thermal conductivity, good thermal shock resistance, and are easily machined into various shapes. Maintaining a non-toxic profile with colorless crystal or white powder options, Boron Nitride showcases remarkable oxidation resistance, excelling at temperatures up to 800 ℃.

More Info About Boron Nitride

Products | Structures | Specification | Material Grades | Applications | Video | FAQs | Safety Data Sheet

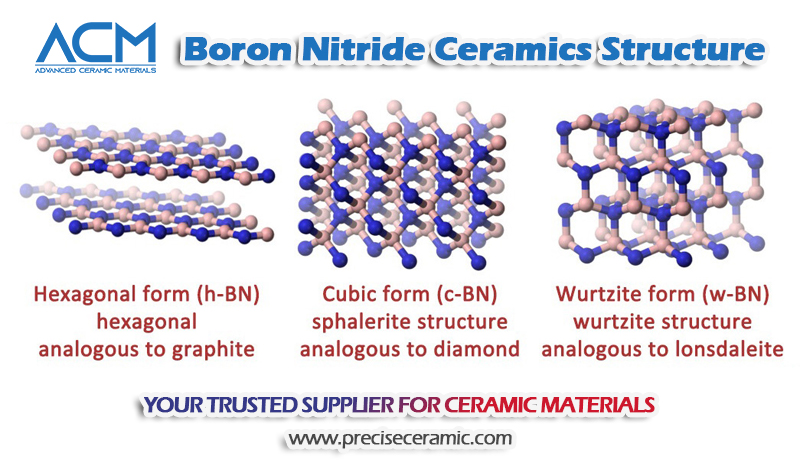

Boron Nitride Structures

The diverse structures of boron nitride ceramics, including hexagonal, cubic, and wurtzite forms, contribute to a range of applications across various industries. Each structure's distinct properties make boron nitride a versatile material with applications in lubrication, cosmetics, abrasives, and high-temperature coatings.

Hexagonal Boron Nitride (hBN):

Hexagonal boron nitride is the most stable phase of boron nitride at ordinary temperature and pressure. Its structure, similar to graphite, makes it the softest and most stable among BN polymorphs. This characteristic renders hBN ideal as a lubricant and an additive in cosmetic products. Additionally, hBN can be produced in graphene-like sheets, allowing the formation of boron nitride nanotubes. The versatility of hBN extends its applications into various industries, leveraging its stability and unique structural properties.

Read more: Hexagonal Boron Nitride vs. Graphene

Cubic Boron Nitride (CBN):

Cubic boron nitride stands out with its exceptional hardness, second only to diamond. Unlike diamond, CBN is insoluble in metals at high temperatures. This property makes CBN valuable as an abrasive material, finding applications in cutting tools and grinding wheels. Furthermore, its oxidation-resistant nature makes it a preferred choice for metal coatings in high-temperature environments. The combination of hardness and resistance to metal dissolution positions CBN as a key material in demanding industrial applications.

Read more: Hexagonal Boron Nitride VS. Cubic Boron Nitride

Wurtzite Boron Nitride (WBN):

The rare wurtzite boron nitride modification shares similarities with lonsdaleite and may even surpass CBN in hardness. While less commonly encountered, the unique properties of WBN make it a subject of interest in materials science. Its potential for extreme hardness opens avenues for applications where high durability and resistance are paramount.

Read more: Wurtzite Boron Nitride - A Simple Guide

Boron Nitride Specification

ACM's production formulations are developed to address the varied application problems in which ceramic components are commonly used. Many industrial applications push the envelope on specific requirements leading to the development of new formulations to successfully address them.

| CAS#: 10043-11-5 | |||

| Powder, F.W. 24.82 | |||

| Item No. | Description | Purity | Lot Size |

| NI05-98 | Boron Nitride Powder Particle Size: 3 µm, 200 mesh or 325mesh |

BN > 98 %, B2O3 < 0.6%, Ca < 0.015%, Si < 0.12% |

100 kg 1000kg Customize |

| NI05-99 | Boron Nitride Powder Particle Size: 3 µm, 200 mesh or 325mesh |

BN > 99 %, B2O3 < 0.4%, Ca < 0.01%, Si < 0.10% |

100 kg 1000kg Customize |

Different Grades of Boron Nitride

| Grade | BN99 (Grade AX05) |

BN-BO (Grade A) |

BNCB (Grade HP) |

BNSIO (M&M26) |

BN-AlN | ZSBN |

| Composition | hBN > 99.5% | hBN > 98% | hBN > 90% Calcium Borate |

hBN 40%, SiO2 60% (M) hBN 60%, SiO2 40% (M26) |

BN+AlN AlBO3 |

hBN > 45% ZrO2 < 45% Borosilicate < 10% |

| Color | white | white | white | white | white | gray |

| Density (g/cm3) |

1.9 | 2.1 | 2 | 2.1-2.3 | 2.5-2.6 | 2.9 |

| Features | • Excellent corrosion resistance • High thermal conductivity • Thermal shock resistance |

• Excellent moisture resistance • Low thermal expansion • Spallation resistance |

• Thermal shock resistance • High thermal conductivity • Moisture resistance |

• High thermal conductivity • High-temperature resistance • Easy machining |

• Good wear resistance • Chemical stability • High thermal shock stability |

|

| Shape | Rod Plate/Sheet Tube Crucible Custom part |

Rod Custom part |

Custom part | Custom part | Custom part | Nozzle Custom part |

| Size | Customized | Up to 410mm x 495mm x 245mm | Up to 410mm x 495mm x 245mm | Customized | Customized | Customized |

*For more information, please contact us.

Boron Nitride Applications

Boron nitride, known for its high thermal conductivity, low coefficient of friction, high dielectric constant, and chemical inertness, finds diverse applications across various industries:

-

Electronics: Boron nitride's excellent thermal conductivity and dielectric properties make it valuable in electronics. It is used in the production of insulating components, heat sinks, and as a substrate for electronic devices.

-

Cosmetics: The unique properties of boron nitride, including its low coefficient of friction and chemical inertness, make it a sought-after ingredient in cosmetics. It contributes to the smooth texture of cosmetic products and provides a desirable feel on the skin.

-

Aerospace: In the aerospace industry, boron nitride is utilized for its thermal stability. It is employed in the manufacturing of components for high-temperature applications, such as rocket nozzles and heat shields.

-

Dental Applications: Boron nitride's biocompatibility and resistance to high temperatures make it suitable for dental applications. It is used in the fabrication of dental tools and components, ensuring durability and performance.

-

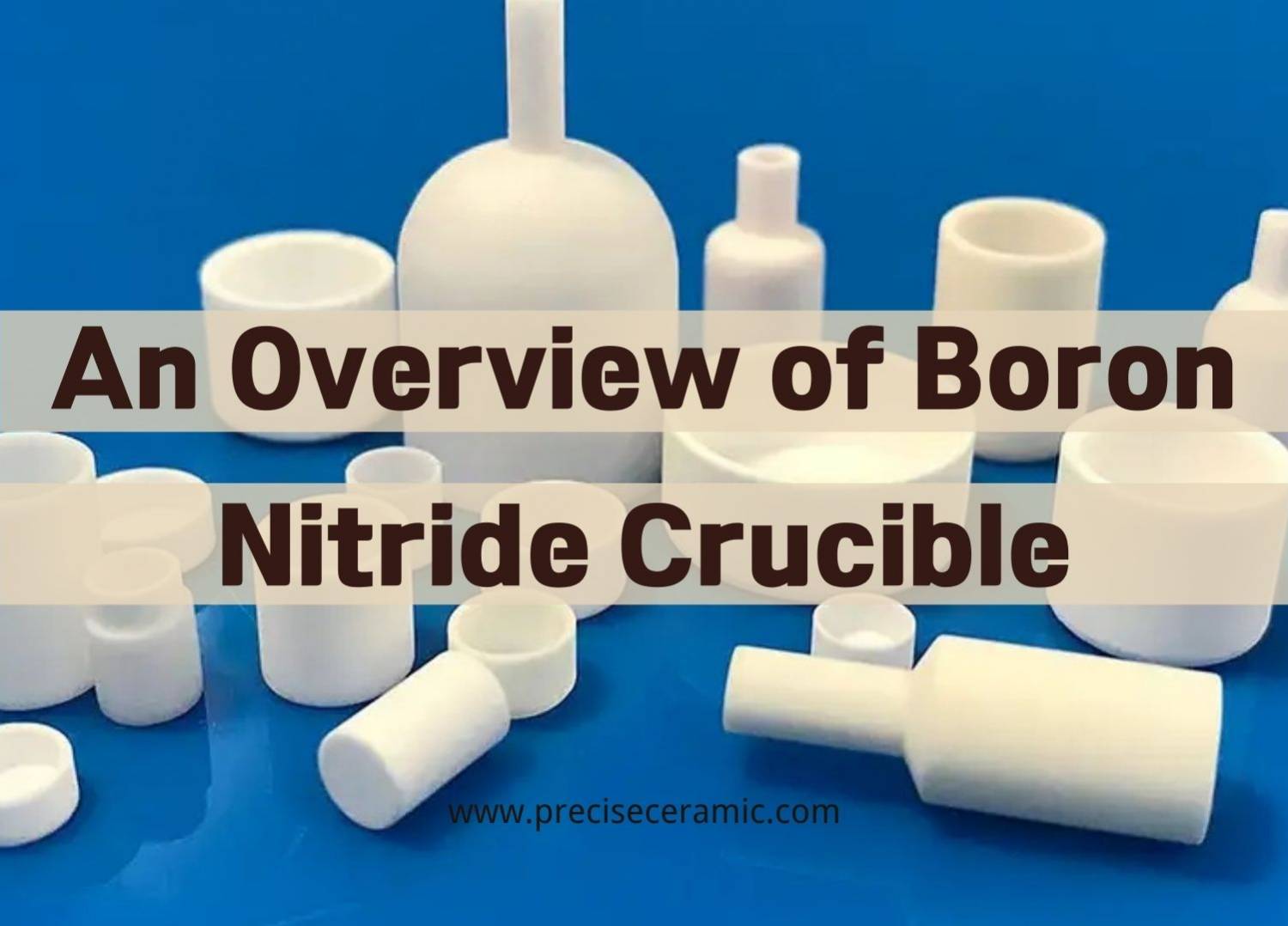

Ceramic Manufacturing: Boron nitride ceramics play a vital role in ceramic manufacturing. Their exceptional thermal and chemical stability makes them ideal for use in kiln furniture, crucibles, and other high-temperature equipment.

-

Nanotechnology: Boron nitride's potential in nanotechnology is significant. The production of boron nitride nanotubes, with a structure similar to carbon nanotubes, opens up new possibilities in nanomaterial applications, including reinforcement in composite materials and advanced nanoelectronics.

-

BN Crucibles: Hexagonal Boron Nitride (H-BN) ceramics are commonly used to manufacture BN crucibles. These crucibles find applications in materials processing and high-temperature experiments due to their thermal stability.

-

Abrasives and Heat Spreaders: Cubic Boron Nitride (C-BN) is utilized as an abrasive material, finding applications in cutting tools and grinding wheels. Additionally, C-BN serves as an ideal material for heat spreaders due to its high thermal conductivity.

-

Dielectric Substrate: Wurtzite Boron Nitride (W-BN) emerges as an ideal dielectric substrate material. Its properties make it suitable for use in optical, electronic, and 2-D graphene-based devices, contributing to advancements in these fields.

Read more: Main Applications of Boron Nitride Ceramics

ACM Ceramic Product Video

Your Boron Nitride Ceramics Supplier

When it comes to high-quality boron nitride ceramic products, look no further than Advanced Ceramic Materials (ACM). As a leading supplier in the industry, ACM takes pride in offering a diverse range of boron nitride ceramics tailored for various applications.

Why Choose ACM?

-

Exceptional Quality: Our boron nitride ceramics adhere to the highest standards of quality. We prioritize precision and reliability in every product, ensuring optimal performance in demanding applications.

-

Extensive Applications Expertise: With years of experience, ACM possesses comprehensive expertise in the applications of boron nitride ceramics. Whether it's for electronics, aerospace, cosmetics, or any other industry, we provide solutions that meet your specific needs.

-

Consultative Approach: At ACM, we understand that choosing the right materials is crucial. That's why our team is dedicated to providing expert advice on materials, design considerations, and application insights. We work collaboratively with our clients to ensure they make informed decisions that align with their requirements.

-

Custom Solutions: We recognize that every application is unique. ACM offers customization options to tailor boron nitride ceramics to your precise specifications. From material composition to design intricacies, we work closely with clients to deliver products that perfectly match their expectations.

Product Range

Explore our comprehensive range of boron nitride ceramic products designed to cater to a variety of industries and applications, including:

- BN Crucibles

- Insulating Components for Electronics

- High-Temperature Equipment Components

- BN Nanotubes and Nanomaterials

- Cosmetic-grade Boron Nitride Powders

Get in Touch

Have questions about boron nitride or other ceramic materials not listed on our website? ACM's dedicated team is here to assist you. Feel free to contact us for inquiries, consultations, or any specific requirements you may have.

At ACM, we go beyond being just a supplier; we are your partner in achieving excellence through advanced ceramic solutions.

Read more: Boron Nitride Overview: Properties, Production, and Uses

| Chemical Formula | BN |

| Mechanical | |

| Density | 1.9 g/cm3 |

| Hardness | 2.26 GPa |

| Modulus of Elasticity | 46.9 GPa |

| Flexural Strength | 75.8 MPa |

| Compressive Strength | 143 MPa |

| Poisson's Ratio | - |

| Fracture Toughness | - MPa m½ |

| Electrical | |

| Dielectric Strength | 95 ac V/mm |

| Dielectric Constant | 4.6 (@ 1 MHz) |

| Volume Resistivity | 10^14 ohm-cm |

| Thermal | |

| Coefficient of Thermal Expansion | 7.54 x 10^-6/°C |

| Thermal Conductivity | 20 W/(m*K) |

| Specific Heat | 16.1 x10^3 J/(Kg*K) |

| Shock Resistance | - |

| Maximum Working Temperature | 2200 vacuum °C |

| Chemical Formula | PBN |

| Mechanical | |

| Density | 2.0-2.2 g/cm3 |

| Hardness | 4 Mohs |

| Modulus of Elasticity | 40 GPa |

| Flexural Strength | 85 Mpa |

| Compressive Strength | 200 MPa |

| Poisson's Ratio | 0.11 |

| Fracture Toughness | 1.5 MPa·m¹/² |

| Electrical | |

| Dielectric Strength | 56 kV/mm |

| Dielectric Constant | 4.0 (@ 1 MHz) |

| Volume Resistivity | >10¹³ ohm·cm |

| Thermal | |

| Coefficient of Thermal Expansion | 1.4 x 10?? /°C |

| Thermal Conductivity | 60 W/m·K |

| Specific Heat | 0.8 J/g·K |

| Shock Resistance | - |

| Maximum Working Temperature | 1800 °C |