What is Zirconia Toughened Alumina?

Introduction

Zirconia toughened alumina (ZTA) products are products made from zirconia and alumina. Zirconia is an oxide of zircon that is usually added to other materials due to its durability. Typically, the fraction of zirconia present in zirconia toughened alumina is about one-tenth or one-fifth. However, this ratio can be adjusted to suit the requirements of the product. ZTA ceramic is a perfect balance between cost and value. ZTA products are stronger than ordinary alumina products. They are also less expensive than pure zirconia products. Hence, with zirconia toughened alumina products, you get to live the best of both worlds. While both zirconia toughened alumina (ZTA) and alumina toughened zirconia (ATZ) have the same raw materials, it is important not to confuse the two composites. In alumina toughened zirconia (ATZ), the ratio of alumina to zirconia is low. In zirconia toughened alumina (ZTA), the opposite is the case.

Zirconia Toughened Alumina ZTA Ceramic

Properties of Zirconia Toughened Alumina

The most notable of the properties of zirconia toughened alumina is its high mechanical strength. The high mechanical strength of zirconia toughened alumina is achieved by a process known as stress-induced transformation toughening. At room temperature, the density of zirconia toughened alumina is about 4.3 g/cm3. It has a high thermal resistance that makes it suitable for high-speed grinding equipment. The maximum working temperature for zirconia toughened alumina is 1923 K while its thermal expansion coefficient is 8.1 × 10-6 C-1. In addition, zirconia toughened alumina has a Poisson's ratio of 0.26, a flexure strength of 130 ksi, and an elasticity of about 47 × 106 psi.

Advantages of Zirconia Toughened Alumina

The advantages of zirconia toughened alumina are responsible for its use in various industries. For starters, zirconia toughened alumina can withstand temperatures of up to 1773 K. This makes it ideal for the manufacture of pieces of equipment that are subjected to high temperatures. Also, zirconia toughened alumina has a higher resistance to corrosion than standard alumina. This makes it highly durable. Furthermore, zirconia toughened alumina has a smooth surface finish compared to regular alumina. This means it can be used in pieces of equipment that are susceptible to friction to prevent wear and tear. In addition, zirconia toughened alumina is a cost-effective composite material because it is less expensive than pure zirconia but more effective than regular alumina. These materials are also biocompatible. This means they have little or no side effects on the human body.

Applications of Zirconia Toughened Alumina

Valve Seals

When choosing a valve seal, it is important to ensure that the material used is durable. It is also important that the material is temperature resistant, corrosion-resistant, and wear-resistant. Zirconia toughened alumina meets these criteria and is usually used as a valve seal.

Joint Replacement

One of the properties of zirconia toughened alumina discussed earlier is its biocompatibility. In addition, this composite material is known to be tough and it has a high flexure strength. This makes zirconia toughened alumina an eligible material for use in joint replacement. Its biocompatibility will ensure that it does not cause harm to the body while its toughness will ensure that it can carry the weight of the body. It is commonly used in hip replacements.

Cutting Tools

Zirconia toughened alumina is hard, wear-resistant, thermally stable, and resistant to friction. These properties make it a great material for making cutting tools. In addition, they are cheaper than other materials, such as diamonds, used in the manufacture of cutting tools.

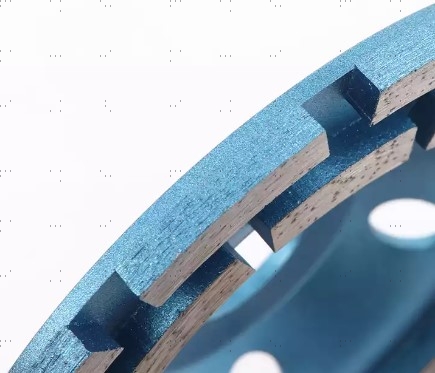

Grinding Wheels

Grinding wheels are important parts of a grinding machine. Grinding wheels are usually made from composite materials. Zirconia toughened alumina is one of the composite materials used in making them. It is usually tough and abrasive enough to be suitable for this use. It is also durable and self-sharpening.

Grinding wheels

Dental Implants

As a result of its biocompatibility, zirconia toughened alumina is commonly used in making dental implants. In addition, zirconia toughened alumina does not corrode easily. These make it possible for dental implants made from zirconia toughened alumina to get wet in the mouth without getting damaged.

Bushings

The function of the bushing is to act as a padding between two structures. It is a type of bearing. Zirconia toughened alumina usually has a smooth finish. This is one of the reasons it is excellent as a bushing. Another reason it is used as a bushing is that it has a high resistance to friction.

Conclusion

Zirconia toughened alumina is one of the most promising materials available in the world today. Due to its many applications and advantages, zirconia toughened alumina is one material you would like to have in your corner.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}