Boron Carbide: Key Properties & Applications

What is Boron Carbide?

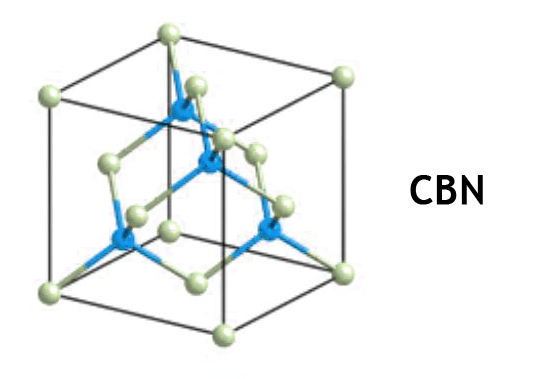

Boron carbide (B4C) is one of the hardest man-made materials utilized in lots of fields. It is the third hardest chemical compound, ranking after diamond and cubic boron nitride (formula CBN). Boron carbide is a dark black crystal, so it is also called a “black diamond”. This strong material does not exist in nature, and could only be obtained from boron and carbon in a furnace. Boron carbide can be shaped by pressing at temperatures exceeding 2000 Thanks to its hardness and other unique properties, boron carbide has significant applications in a variety of industries. Boron carbide, with a combination of special properties, is now manufactured in large quantities. It was discovered in the mid of the 19th century as a by-product of reactions under high temperatures. Yet this compound was not known to the world until the 1930s. Boron carbide is produced in a heat-resistance furnace. Only 15 percent of raw material can be converted into B4C in this process. Thereafter, the valuable boron carbide has become an important material for bulletproof armors, nuclear control rods, abrasives, etc. Further Reading: An Overview of Boron Carbide Ceramics

Key Properties of Boron Carbide

This hard material is mainly characterized by:

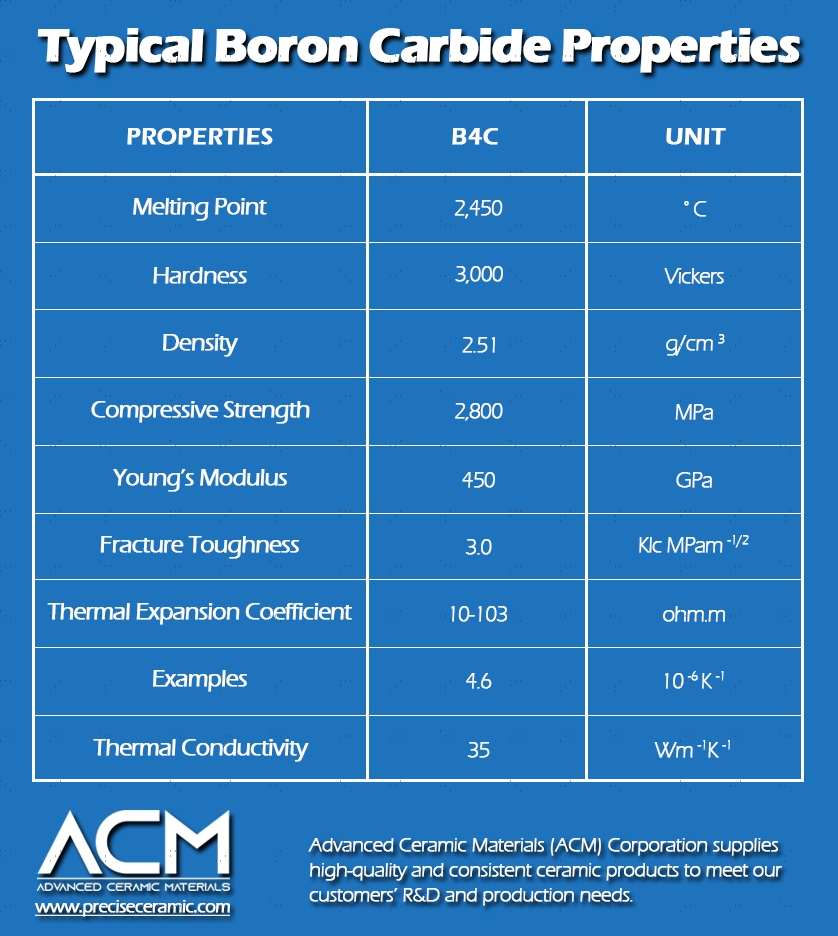

- High Hardness: The Mohs hardness of boron carbide is between 9 and 10. Such stiffness and strength help boron carbide get the nickname “black diamond”.

- Low Density: It has a low density of about 2.52 g/cm3 in the solidified form. Such lower density makes boron carbide a lighter choice for armor making.

- Chemical Inertness: Boron carbide rarely reacts with other chemicals. Such chemical stability leads to plenty of applications for this substance.

- Nuclear Ability: Boron carbide has a high cross-section to capture neutrons. So the boron carbide substance could serve as a neutron absorber and neutron detector in nuclear reactors.

Major Applications of Boron Carbide

The industrial uses of boron carbide include:

B4C as Protective Armors

Boron carbide is used to make protective tools to resist the impact of sharp objects like bullets, shrapnel, and missiles. It is usually combined with other composites during processing. Because of its high toughness, B4C armor is difficult for the bullet to penetrate. B4C material could absorb the force of the bullet and then dissipate such energy. The surface would shatter into small and hard particles later. Using boron carbide materials, soldiers, tanks, and airplanes could avoid serious injuries from bullets.

ACM’s Boron Carbide Bulletproof Plate provides strong protection for humans, motors, aircraft, etc. B4C bulletproof material has been widely used. It is quite easy to find B4C bulletproof glass, bulletproof vests, and bulletproof armor for military use. Boron carbide ceramic was applied to famous tanks like the current German Panther-Ⅱ, the British Challenger series, and the former Soviet Union’s T-72. It also appeals to airborne engineers since they could benefit from its low density and high hardness. Many more anti-ballistic products are using B4C ceramics thereafter.

Further Reading: Application of Boron Carbide Ceramics in Body Armor

B4C in Nuclear Reactions

Boron carbide is an extensively used control material in nuclear power plants for its neutron-absorbing ability, low price, and abundant source. It has a high absorption cross-section. Additionally, it produces no radionuclides, so the residual radioactivity level would be reduced. B4C ceramic is also an ideal shielding material in nuclear industries due to its heat resistance, no radioisotope production, and low cost. These products are available in powder form or solid form. ACM’s high-quality B4C products are the perfect choice for nuclear applications like control rods, shielding, and shut-down pellets.

Other B4C Applications

Boron carbide products serve as good abrasives for their outstanding stiffness. Thanks to such hardness, boron carbide could be used to polish and shape hard materials like metals. We could also find B4C material in cutting and grinding machines. It can be employed for cutting different alloys like Titanium alloy, aluminum alloy, and stainless steel. Due to such abrasion resistance, this tough material could be used as wear parts like blasting nozzles, wire-drawing dies, and thread guides.

Boron carbide is also well known for its excellent chemical properties like high corrosion resistance and heat resistance. So the products made from boron carbide are less likely to undergo corrosion. It is quite common to find high-security padlocks, tear-resistant coatings, and pipes and nozzles for very abrasive materials using boron carbide because of its inertness.

Conclusion

Boron carbide is an essential material with lightweight and great mechanical strength. Advanced Ceramic Materials (ACM) offers boron carbide ceramics of good quality in powder form and solid form for further processing. Our products have high purity and competitive prices. ACM also has much experience in supplying a range of B4C products, including plates, rods, and powers for applications in different sectors. There are many more related products on our website. Hope we can offer helpful advice and give you a better understanding of boron carbide and its various uses. For further details about B4C ceramic materials, please check https://www.preciseceramic.com/.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}