Hexagonal Boron Nitride Used as A Substrate for 2D Materials

Hexagonal boron nitride (h-BN) is a two-dimensional compound with many applications. It is a structural type of boron nitride ceramics, the other two types are cubic-BN and wurtzite-BN. This article is going to focus on HBN used as a substrate for 2D materials.

What Are 2D Materials?

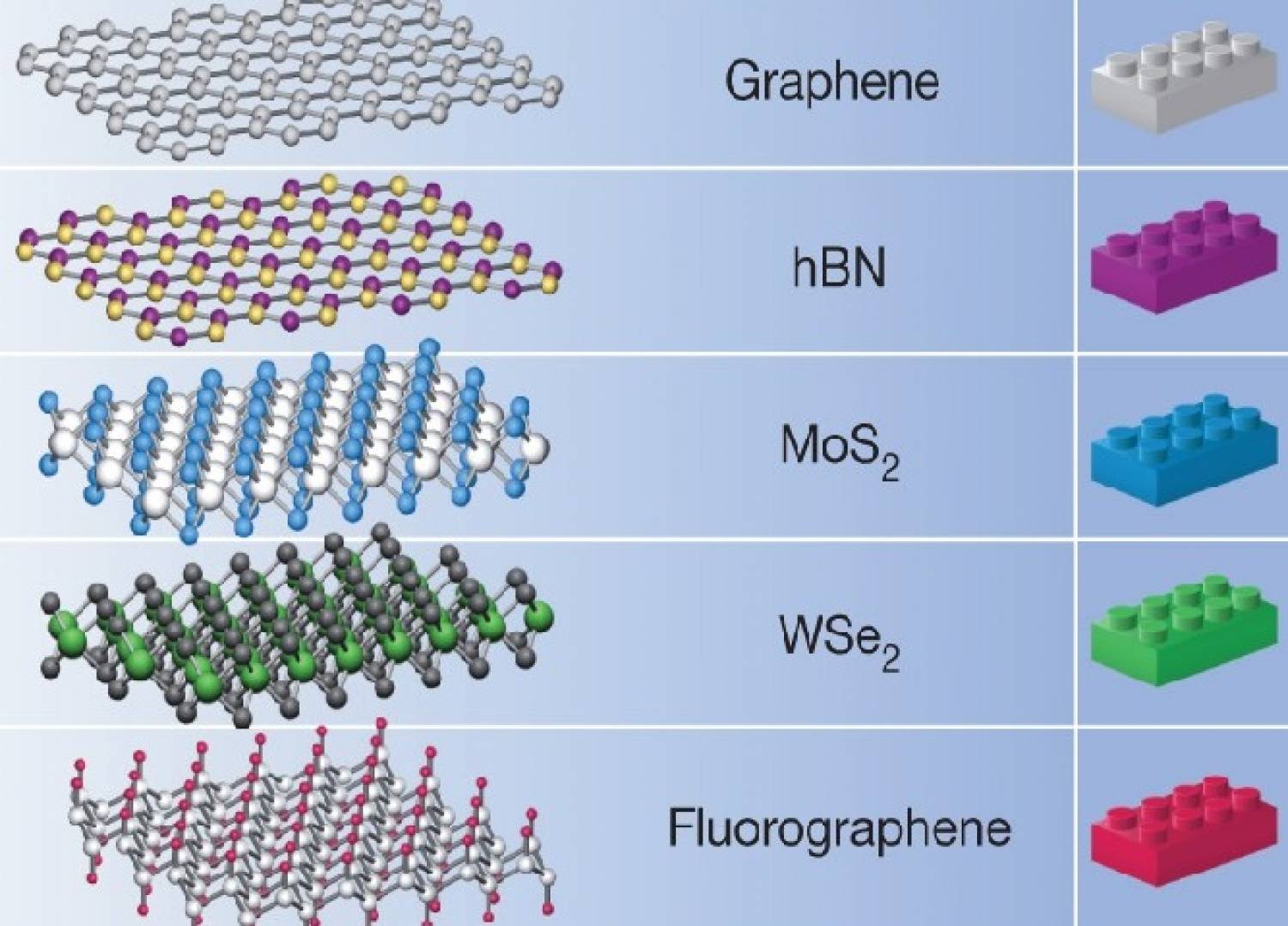

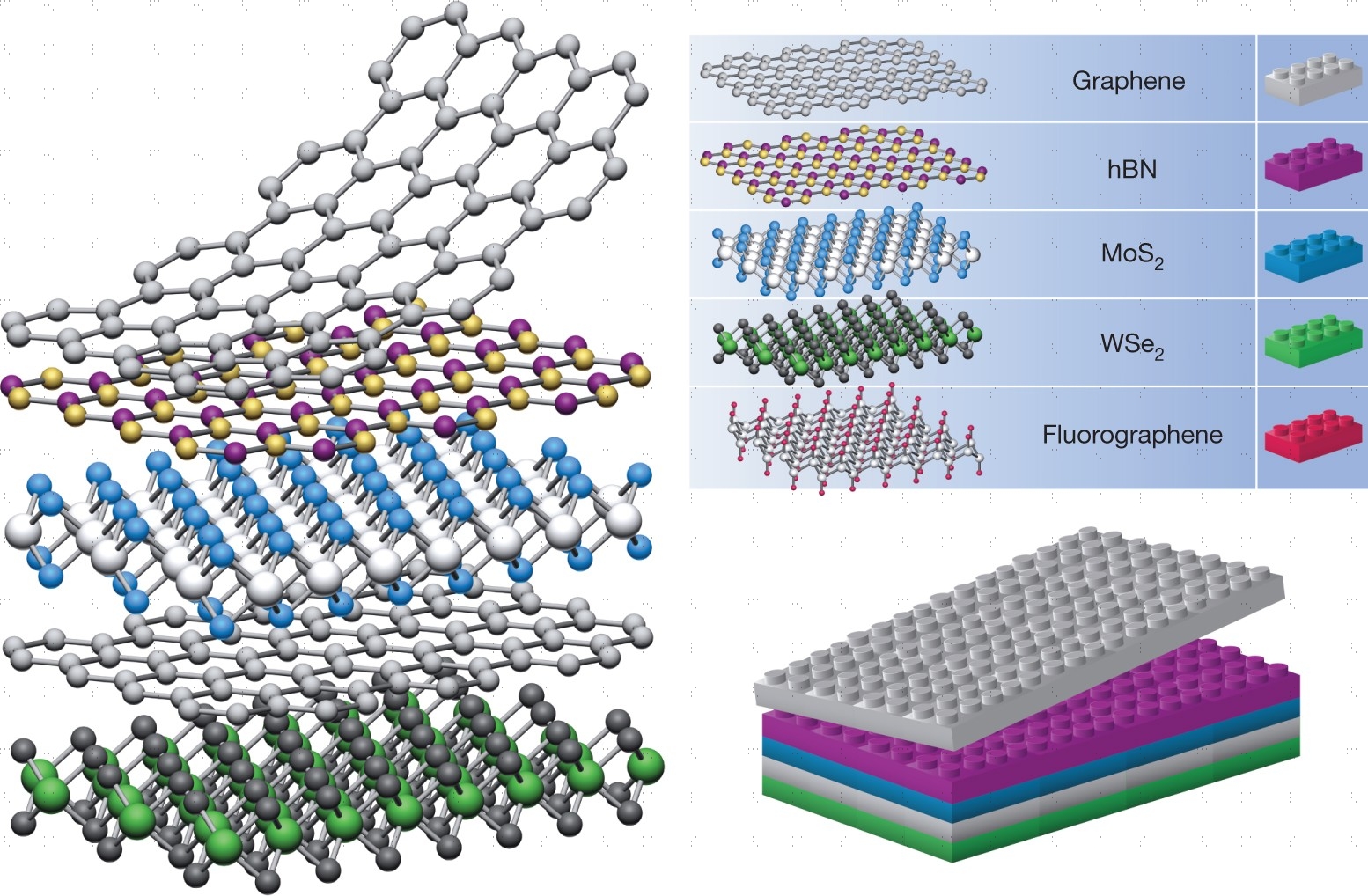

2DM refers to two-dimensional material in that all the atoms are set together within a single layer. From the micro perspective, 2DM are nanoscale materials. 2DM can be classified as elements, metallic compounds, organics, and salts. All these materials have impressive mechanical, chemical, and optical properties.

Advantages of 2D Materials

2D materials have various advantages compared with bulk materials.

- 2DM shows strong tensile strength. The typical 2DM graphene has the highest tensile strength in nature.

- The surface area-to-volume ratio of 2D materials is relatively higher, so 2DM could have more contact with reactants.

- 2DM also has perfect optical features.

Geim, A., Grigorieva, I. Van der Waals heterostructures. Nature 499, 419–425 (2013). https://doi.org/10.1038/nature12385

Manufacturing of 2D Materials

There is a range of production methods to get this single-layer material from bulk materials.

- Mechanical exfoliation employs mechanical normal forces and lateral forces to overcome van der Waal forces to produce quality 2D materials. However, the efficiency and yield of mechanical exfoliation are relatively lower.

- Liquid exfoliation overcame these weak points by using organic solvents as intermedium to enhance the mechanical forces. Nevertheless, 2DM made from liquid exfoliation could not apply to some optical sectors because there are some organic solvent residuals left at last.

- Chemical vapor deposition (CVD) is a highly efficient method. The deposition takes place in a heated chamber with controlled pressures, temperatures, and reaction times. Atoms hit the substrate, and then 2DM forms on it.

Chemical vapor deposition has become a prime manufacturing means recently. Related reading: 2D Materials: Rising Star for Future

Why Is H-BN An Ideal Substrate?

Properties of Hexagonal Boron Nitride

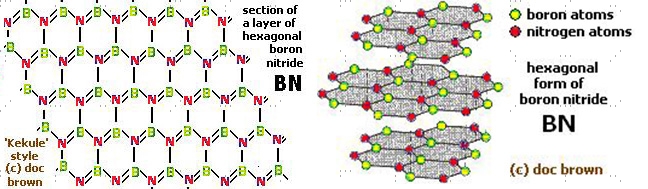

Hexagonal boron nitride is a stable compound. Similar to its counterpart graphite, h-BN has a single two-dimension layer. Additionally, all the boron atoms and nitride atoms are held together by weak van der Waals forces instead of strong covalent bonds. Hexagonal boron nitride has many other outstanding features:

- H-BN has remarkable thermal stabilities. It remains stable at temperatures up to 1000 °C in air. H-BN could stand higher temperatures in a vacuum and an inert atmosphere.

- It is chemically stable, and it could stand usual acids. But please do not put it in alkaline molten salts.

- Hexagonal boron nitride nanoribbons (BNNRs) have a great thermal conductivity of about 1700–2000 W/(m·K).

With these notable properties, hexagonal boron nitride found many applications in electronics, batteries, thermal applications, and other sectors.

Hexagonal boron nitride structure

Importance of Substrates in CVD

As we mentioned above, chemical vapor deposition is a commonly used method to make high-quality 2D materials with ideal mechanical, chemical, thermal, and optical properties. The substrate plays an essential part during the deposition process. For one thing, CVD is affected by temperatures, pressures, precursors, and other elements. For another, substrates affect the size, thickness, nucleation, and crystal quality of 2D materials. Therefore, substrates are of great importance to the synthesis of 2D materials.

Conventional Substrate Materials (SiO2/Si)

SiO2/Si substrate is one of the substrates used in chemical vapor deposition to manufacture 2D materials. It is extensively employed due to the following reasons.

- Optical Properties: It is quite easy to observe 2D materials within SiO2/Si substrates. And the intensity of the optical signal is associated with the thickness of SiO2/Si substrates.

- Mechanical Properties: SiO2/Si has a high melting point, and it is compatible with the silicon process.

- Chemical Properties: Its chemical stability contributes to a better performance in chemical vapor deposition.

HBN Substrate VS Silicon Substrate

Hexagonal boron nitride becomes an alternative for SiO2/Si substrates recently. It has a variety of advantages over SiO2/Si.

- The hexagonal boron nitride substrate has an ideal structure. H-BN atoms are put together by van der Waals forces, while SiO2 and other traditional materials are held together by covalent or ionic bonds. Since chemical bonds are much stronger than van der Waals forces, the single layer of hexagonal boron nitride is quite easy to break and manipulate.

- The defect density requirement is so stringent. For example, if SiO2/Si is used as insulators, the defect density must be less than 1e-16 cm-3.

- Hexagonal boron nitride is more stable thermally and chemically over high-temperature ranges. H-BN is also resistant to corrosion and oxidation.

Conclusion

In short, hexagonal boron nitride ceramic is an ideal choice to make substrates for 2D materials because of its single layer and remarkable stability. It has numerous advantages over SiO2/Si and other substrate materials. Advanced Ceramic Materials (ACM) provides lots of boron nitride products, and we have rich experience in the manufacturing and sales of ceramic products. Check our website for more information.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments

- Aluminum Oxide Ceramics: Properties and Applications

- Boron Nitride Coatings: The Solution for Molten Metal Applications