Application of Zirconia Ceramics in Automotive Industry

Ceramics, in general, have advanced applications in our daily lives. But they also play vital roles in many industries, including the automotive industry. In the automotive industry, the most commonly used advanced ceramics are zirconia ceramics. Zirconium oxide ceramic materials have superior mechanical properties, making it possible to process them into auto parts. In this post, we’ll discuss the application of zirconia ceramics in the automotive industry. However, before we delve into that, let's look at the properties of zirconia.

Properties of Zirconia

Zirconia is also known as zirconium dioxide and zirconium oxide. It is a crystalline metal oxide popularly used in the ceramics industry. Zirconia is known for its high thermal resistivity, mechanical resistance, strength, toughness, and abrasive properties - all of which account for its widespread applications in different fields, such as electronics, biomedical, optical, jewelry, and in daily life. Zirconia is one of its most popular forms of cubic zirconia, a colorless and mechanically tough cubic crystalline compound. Considering its application in the automobile industry, here are the most relevant physical and chemical properties of zirconia:

High mechanical resistance: Zirconia has very high mechanical resistance. It is resistant to crack formation and mechanical stress. This is why it is widely used in applications where high tensile strength and fracture toughness is required.

High-temperature resistance and expansion: Zirconia has a melting point of 2700 C and a thermal expansion coefficient of 1.08×10-5 K-1. This property, in particular, makes zirconia very useful in applications where heat-resistant materials are needed, especially in refractories and high-temperature industries.

Low thermal conductivity: With a thermal conductivity of 2 W/(m·K), zirconium dioxide or zirconia is perfect for applications where heat needs to be contained.

Resistant to chemical reactions: Zirconia is chemically inert and unreactive. The substance has been shown to exhibit resistance to most chemical reactions. As a result, it is suitable for application in industries that use different processing chemicals during processing. However, zirconia will dissolve in concentrated acids such as sulfuric or hydrofluoric acid.

Related Post: Zirconia Ceramics Application in Medical Field

Applications of Zirconia in the Automotive Industry

In line with the established properties of zirconia ceramics, automotive manufacturers have used zirconia in making auto parts, and this is mostly because of its toughness, mechanical resistance, and thermal conductivity.

As insulating materials in the engine combustion chamber

Note that zirconia has a small thermal conductivity and a relatively high thermal expansion coefficient. This makes it suitable for making insulating materials used in parts where excellent thermal insulation properties are required. In particular, zirconia ceramics are used in the manufacture of insulating materials covering automobile engine combustion chambers.

As cylinder head bottom plate

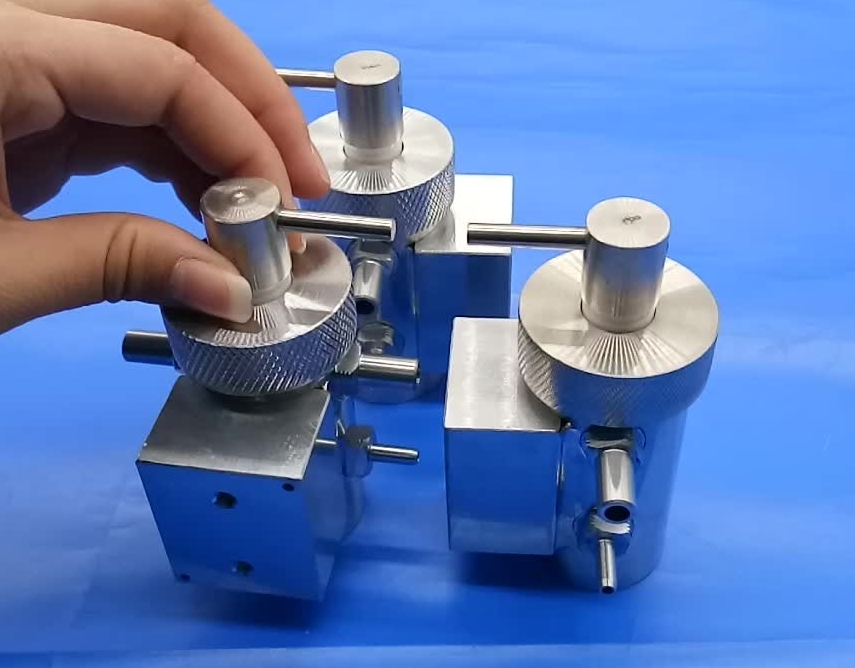

Zirconia can also be used in fabricating cylinder head bottom plate, cylinder liner, piston crown, valve seat ring, and other important auto parts. But large scale commercial applications of zirconia in this regard are yet to be attained because the harsh working conditions of the engine combined with the strength of ceramic components change greatly at high temperatures.

Application of zirconia ceramics in automobile engines

A very important ceramic used in this regard is zirconia. It is sintered from inorganic non-metals. Although alumina ceramics were used in the past, zirconia ceramics are now preferred because they are several times stronger than alumina ceramics, and, as mentioned earlier, can withstand very high temperatures. Based on past experiments, it has been shown that enclosing the combustion chamber with ceramic materials with good thermal insulation properties helps to increase the thermal efficiency of the engine. Zirconia ceramic parts are used in this manner in diesel engines. Also, further studies are ongoing to understand the use of new ceramic piston pins and piston rings, and other moving parts. It is expected that reducing the weight of these parts will help to improve engine efficiency.

Application in sensors

Zirconia ceramic sensors are used in the shock absorbers found in some luxury cars. The shock absorber is developed by leveraging the positive piezoelectric effect, inverse piezoelectric effect, and electrostrictive effect of sensitive ceramics like zirconia ceramics. The shock absorber can recognize and self-regulate the road and helps in minimizing the vibration of cars on rough roads.

Conclusion

Zirconia ceramic has, over time, proven to be an essential material in different industrial processes. It plays a particularly important role in the manufacture of many automobile parts. The wide application of zirconia stems from its high resistance to chemical reactions, thermal expansion, and mechanical abrasions, as well as its low thermal conductivity. Thank you for reading our article, and we hope it can help you to have a better understanding of zirconia ceramics and its use in the automotive industry. For more information, please visit https://www.preciseceramic.com/.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments