An Introduction to Yttria Stabilized Zirconia

Introduction

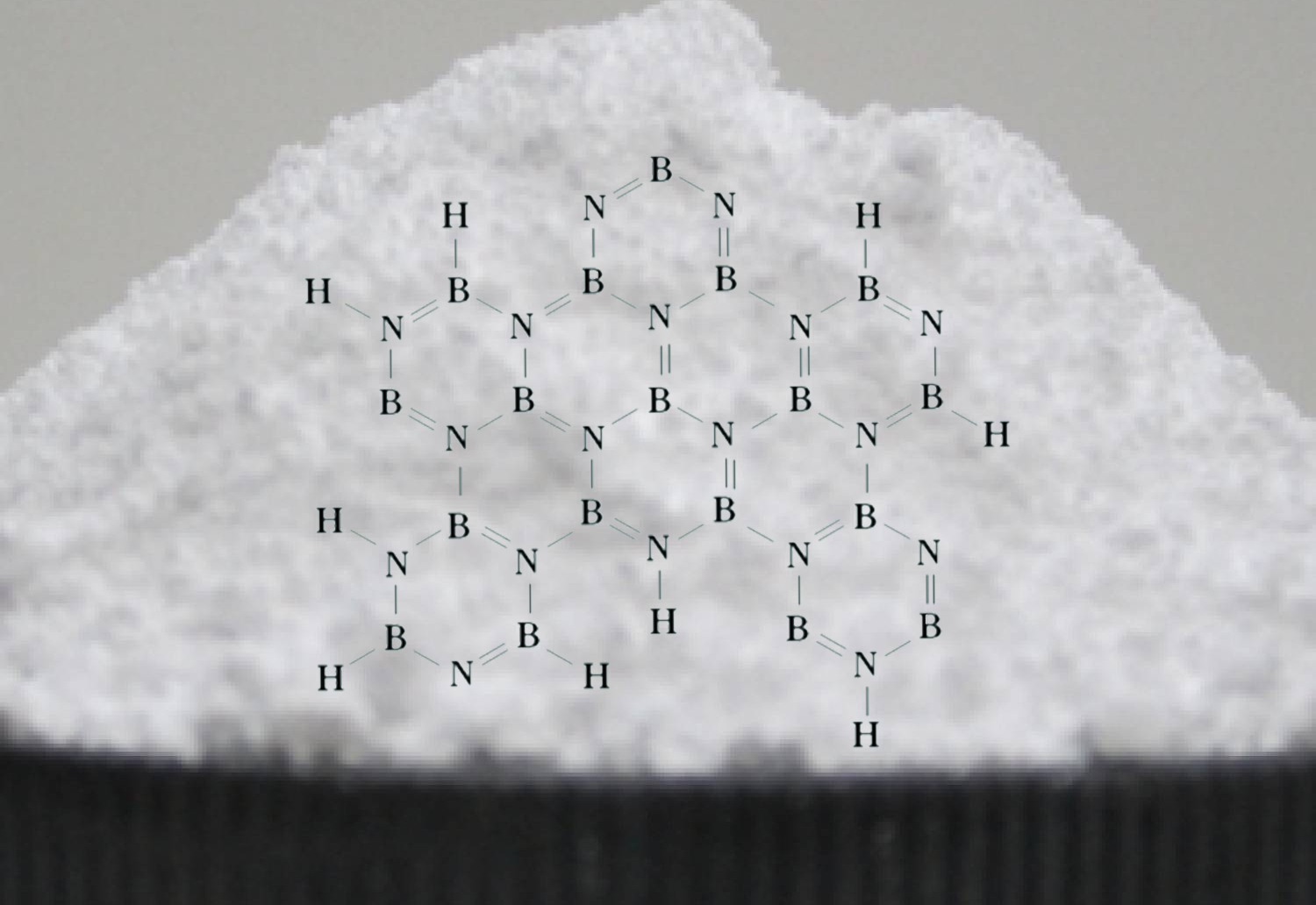

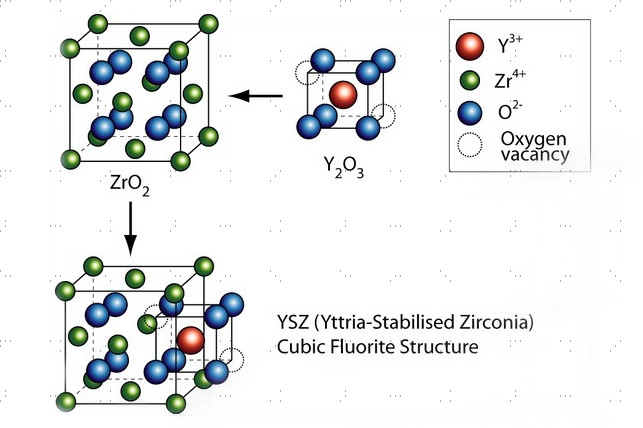

Yttria stabilized zirconia is a ceramic material. It is formed in a bid to stabilize the cubic crystal structure of zirconium dioxide at room temperature. To stabilize the crystal cubic structure of zirconium dioxide, manufacturers add yttrium oxide which is also known as yttria. Yttria is not the only material that can be added to stabilize zirconia. Other materials like magnesium oxide, calcium oxide, and cerium oxide are also used. Before zirconia is stabilized, it has monoclinic, tetragonal, or cubic crystal phases. However, after it is stabilized by yttrium oxide, it has a cubic phase alone. Yttria stabilized zirconia is a wear-resistant and strong material. Similar materials include magnesia-stabilized zirconia, calcia-stabilized zirconia, and ceria-stabilized zirconia. These materials have similar properties and applications.

Yttria-stabilized zirconia (YSZ) crystal structure. Source: Wikipedia

Advantages of Yttria Stabilized Zirconia

Ever wondered why yttria-stabilized zirconia might be the perfect choice for you Here are some advantages of yttria-stabilized zirconia.

High Strength

Yttria stabilized zirconia has a high strength that makes it suitable for applications involving materials with high strength.

High-temperature Resistance

Yttria-stabilized zirconia has high-temperature resistance. This means that they can be used to make structures that are used in a high-temperature environment without being jeopardized. They can be used as refractory materials because they are not easily destroyed by high temperatures.

Corrosion Resistance

YSZ is a corrosion-resistant material. Therefore, it lasts longer than other materials that are not. Yttria stabilized zirconia is not affected by acids or other chemicals when they come in contact with it. It can be used as a coating or in parts of machines that are prone to corrosion without being marred.

Oxidation Resistance

Yttria stabilized zirconia shows oxidation resistance. This means that YSZ does not show any change when it is exposed to oxygen. It is a durable and reliable material. Due to its oxidation resistance, yttria-stabilized zirconia can be used as a coating. In addition, it can be used to make parts of a machine susceptible to wear. Materials coated with yttria-stabilized resistance are not likely to rust.

Yttria Stabilized Zirconia Grinding Media

Applications of Yttria Stabilized Zirconia

Dentistry

Yttria stabilized zirconia is commonly used in dentistry. Being a hard and chemically inert material, it is often used in manufacturing tooth crowns. Tooth crowns are placed in the mouth which is a moist environment. When they are made with YSZ, they are protected from corrosion and other threats posed by moisture

Refractory Material

YSZ is resistant to heat decomposition. Because it is resistant to high temperatures, yttria-stabilized zirconia is often used as a refractory material. Refractory materials can be used to line furnaces, hold hot objects, and provide thermal insulation.

Production of Solid Oxide Fuel Cell

Yttria-stabilized zirconia is used in producing solid oxide fuel cells. It serves as a solid electrolyte. The job of the solid electrolyte is to allow oxygen ion conduction while preventing electronic conduction. The electrolyte is usually used at temperatures between 800-1000 °C. This does not pose any threat to YSZ because it is high temperature-resistant.

DIY Cement

Yttria stabilized zirconia is used in making water-based pastes that are ingredients for DIY cement. The final product is high temperature- resistant and hard

Coating

Yttria stabilized zirconia is wear-resistant, corrosion-resistant, and oxidation-resistant. These properties make it suitable as a coating for materials that are susceptible to wear, corrosion, and oxidation.

Other Forms of Stabilized Zirconia

Magnesia Stabilized Zirconia

Magnesia-stabilized zirconia is another form of stabilized zirconia. It is even more temperature resistant than yttria-stabilized zirconia and has a lower thermal conductivity. In addition, MSZ is more stable in moist environments than YSZ. Magnesia stabilized zirconia is a strong, tough, wear-resistant, and corrosion-resistant material.

Calcia-Stabilized Zirconia

Calcia-stabilized zirconia is a form of stabilized zirconia formed by adding calcium oxide to zirconium dioxide. Its melting point is approximately 2700 °C and its density is about 5.6 g/cm3. Calcia-stabilized zirconia is usually used in making refractory materials. It is known to improve the density, thermal shock resistance, and corrosion resistance of such materials. It is also popularly used as a coating.

Ceria Stabilized Zirconia

When it comes to resistance to moisture, ceria-stabilized zirconia is a better option than magnesia-stabilized zirconia as well as yttria-stabilized zirconia. It is commonly used as a component of sensors, fluid control systems, and pumps. Ceria-stabilized zirconia has high strength, corrosion resistance, and high-temperature resistance.

Further Reading: Advantages of Yttria Stabilized Zirconia (YSZ) Compared to Other Stabilizers

Conclusion

Yttria stabilized zirconia is a ceramic material that is formed to stabilize the cubic crystal structure of zirconium dioxide at room temperature. Yttria stabilized zirconia is a popular choice for applications that require a high temperature-resistant, wear-resistant, oxidation-resistant, and strong material. For more information about high-quality advanced zirconia ceramic materials, please visit https://www.preciseceramic.com/.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}