AC3493 Bubble Alumina Tube

- Catalog No. AC3493

- Material Al2O3

- Purity >99%

- Bulk Density 0.96 g/cc

Datasheet

Inquiry

AC3493 Bubble Alumina Tube

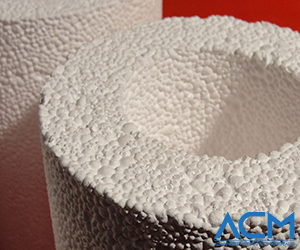

Bubble Alumina Tube Description

Bubble Alumina is a rigid, low-density, insulating refractory. Bubble Alumina’s structure consists primarily of closed air-filled thin-walled cells which combine to give it exceptional hot strength and low thermal conductivity. This makes Bubble Alumina an effective high-temperature thermal insulator in structural applications. It is appropriate for use at temperatures as high as 1825℃. It is pre-fired, contains no organics, and exhibits high microwave and RF transparency. Its high alumina content makes it compatible with many extreme chemical environments.

Bubble Alumina Tube Specifications

| Color | White |

| Composition (Al2O3), % | 99+ |

| Bulk Density, g/cc | 0.96 |

| Cold Crush Strength, Mpa (psi) | 11 (1600) |

| Shrinkage, % Average of Length & width | |

| 4 hr. at 1750℃ | 0.19 |

| 4 hr. at 1800℃ | 1.77 |

| Specific Heat, Btu/lb ℉(J/kg·K) | 0.27 |

Bubble Alumina Tube Applications

* Structural hot face refractory in high-temperature furnaces and thermal process systems with temperatures of 1825℃.

* Backup insulation in crystal growth furnaces with temperatures in excess of 2000℃.

* Low-mass kiln furniture.

* High-temperature load-bearing insulation.

Packaging

Our Bubble Alumina Tube is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Request a Quote

-

Attachment (Optional)

No file chosen