Applications of Boron Nitride Thin films

Thin films forming a group of composite materials are becoming more widely used in optics, electronics, and the construction of machines. The main tasks of lubricating coatings are the improvement of mechanical properties (hardness, elastic modulus), raise of corrosion resistance, and, above all, reduction of friction and wear.

One of the most promising materials for that purpose, which fulfill all mentioned requirements, is boron nitride (BN). Boron nitride is an inorganic chemical compound, consisting of the same number of boron and nitrogen atoms and is isostructural and isoelectronic with carbon. The most common and stable phases are soft hexagonal boron nitride hBN and hard cubic boron nitride CBN.

Read more: Hexagonal Boron Nitride VS. Cubic Boron Nitride

All phases of boron nitride have a number of common properties like high thermal and chemical stability, high corrosion resistance, no solubility in water, and most common acids. Unlike diamond, BN phases do not react with ferrous metals below the temperature of 1500 C. At the same time, there are significant differences between phases with sp2 and sp3 hybridization. Sp2 phases, like hBN, and rBN are very soft and possess lubricating abilities similar to graphite.

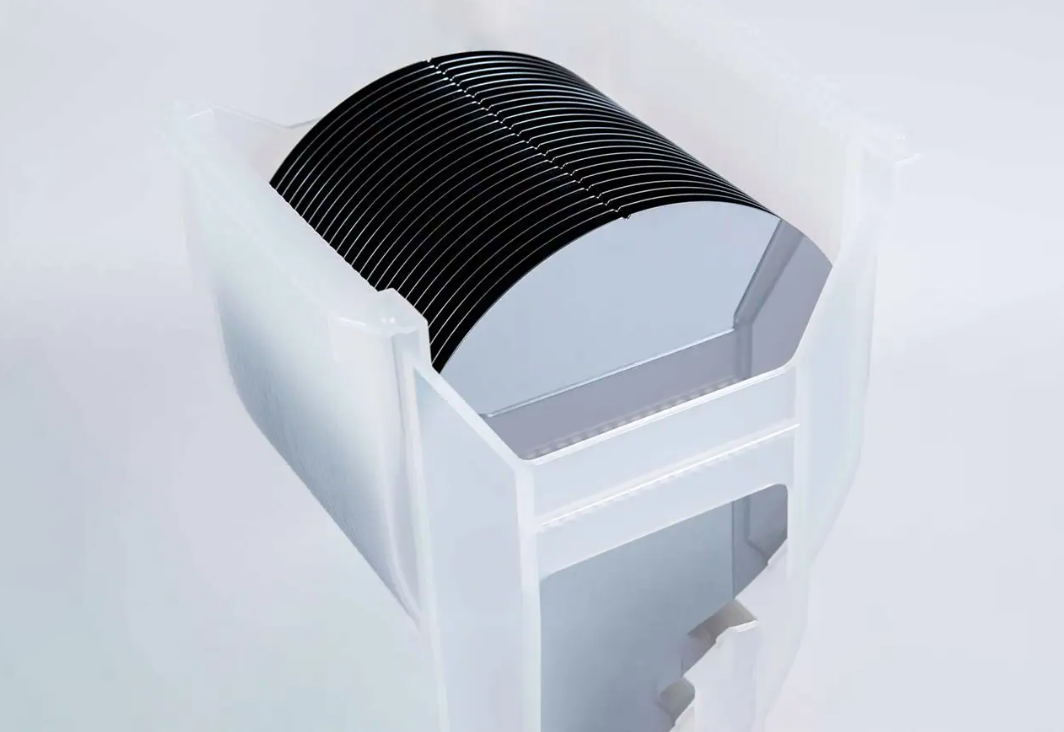

Hexagonal boron nitride has good lubricating properties both in low and high temperatures (up to 900o C, even in presence of oxidizing atmosphere). Due to its structure (strong bonds within the layer, weak between layers) hBN shows anisotropic properties, such as in the case of conductivity and thermal expansion. Due to the covalence-ionic nature of chemical bonds, has very high hardness. It is characterized by a low friction coefficient and high wear resistance. In addition, the layered nanocomposites composed of hard cBN and soft hBN phases with good lubricating abilities are ideal for covering the surfaces of bearings. Wurtzite boron nitride (WBN) with a hardness similar to cBN, has lower thermodynamic stability and the tendency to transform to a stable hBN phase. In the vast majority of cases, BN coatings are deposited on a silicon substrate, due to the fact that the highest content of the cBN phase was observed on hard, covalence substrates like Si, SiC, diamond, and sintered carbides.Thin BN films deposited on soft metals (Al, Ag) show significantly lower content of cubic phase than those deposited on hard metallic substrates (Nb, Ta, Ni).

In conclusion, boron nitride (BN) is a highly promising material for lubricating coatings due to its excellent mechanical properties, high corrosion resistance, and low friction coefficient. Hexagonal boron nitride (hBN) has good lubricating properties even at high temperatures and is characterized by its anisotropic properties and high wear resistance. The layered nanocomposites composed of hard cubic boron nitride (cBN) and soft hBN phases are ideal for covering bearing surfaces. BN coatings are commonly deposited on hard substrates such as silicon, silicon carbide, diamond, and sintered carbides to achieve the highest content of cBN phase. The content of the cubic phase in BN films is significantly lower when deposited on soft metals such as aluminum and silver. Overall, thin films forming a group of composite materials, such as BN, are becoming increasingly widely used in optics, electronics, and machine construction due to their desirable properties.

Advanced Ceramic Materials (ACM) supplies high-quality boron nitride ceramics and related products to meet our customers’ R&D and production needs. Please visit https://www.preciseceramic.com/ for more information.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}