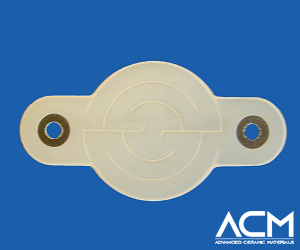

PBN Heater: Properties and Uses

Introduction

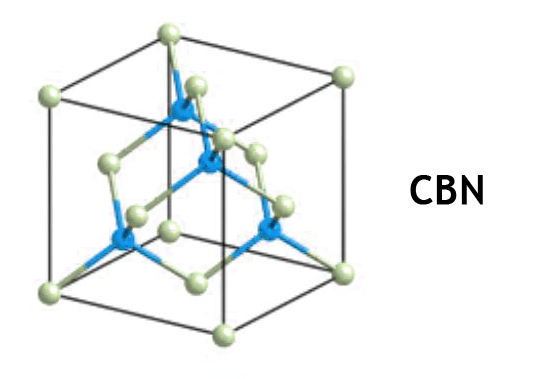

Pyrolytic boron nitride (PBN) is the perfect material for applications needing extremely high strength, a small coefficient of thermal expansion, and thermal shock resistance because it combines excellent electrical resistance and thermal conductivity. PBN is a non-toxic, dense, and extremely pure material that can be put into 2D or 3D shapes, such as crucibles, boats, plates, wafers, tubes, and bottles, or used as a coating for graphite. When coated on graphite, PBN exhibits excellent temperature stability up to 1700°C, resists thermal shock, and resists gas corrosion in environments that include most molten metals (Al, Ag, Cu, Ga, Ge, Sn, etc.), acid, and hot ammonia. PBN is known for its directional thermal conductivity and excellent thermal diffusivity. Pyrolytic Boron Nitride in ceramic form is a highly pure ceramic with exceptional chemical and heat resistance that has found great use in ceramic heater production. PBN is used to create compound semiconductors and molecular-beam epitaxy, which benefit from its properties, in crucibles. The range of possible applications for PBN is growing, and some of these applications include highly functional PG/PBN heaters for semiconductor fields and CIGS-based thin films for photovoltaic energy production.

Properties of PBN Heater

Electrical insulation is provided by the PBN layers and thermal gradients can be modified to fit particular needs. It alleviates the problem of contamination and outgassing. Below are more of the physical and chemical properties of PBN heaters.

- PBN heaters typically have about 1400 °C -1600°C temperature in a vacuum.

- The maximum air temperature is 900°C.

- Thrives well in corrosive conditions, ultra-high vacuum, and high vacuum environments.

- PBN heaters exhibit an extremely quick ramp rate and a minimum mass.

- PBN protects the extremely inert PG element from the deposition product.

- Samples may be directly placed on the ceramic plate element of a heater.

- PBNs are exceptionally stable in vacuum or inert environments and exceedingly pure (99.99% or more).

- PBN heaters are unaffected by vibration.

- They have excellent performance even at very high pressure.

- They are chemically unaffected by the most aggressive gases or liquids.

- They are unaffected by other molten metals.

- PBN heaters are quite durable with long material life

- They exhibit higher resistance for low voltage.

- PBN heaters also have low thermal masses.

Uses of PBN Heater

PBN heaters are customizable. Its potential applications include MOCVD heating, Metal heating, evaporation heating, superconductor substrate heating, sample analysis heating, electron microscope sample heating, semiconductor substrate heating, and etc. For most uses, you’ll see them being combined with Pyrolytic graphite (PG). Below are some other uses of PBN materials.

-

Coating with PBN

PBN is frequently used in liquid phase epitaxy and MOCVD to shield the graphite components of the apparatus. It can also be used as the exterior layer of a graphite heater (PG/PBN heater) to keep the heating element from volatilizing at high temperatures. The PBN film can also be utilized as a diaphragm or passivation layer in the semiconductor etching process due to its extraordinarily high chemical inertness.

-

Container for single crystal formation for compound semiconductors

Compound semiconductor single-crystal growth demands highly strict conditions, including temperature, raw material purity, and growth vessel purity (for example, GaAs, InP, etc.). The best container for compound semiconductor single-crystal growth right now is PBN, and it cannot be replaced.

-

PBN sheets and rings

PBN has a high purity of more than 99.99%, can be heated to 2300 °C in an ultra-high vacuum without decomposing, and doesn't release gas impurities at high temperatures. Many other good qualities allow PBN to be processed into a variety of shapes. Rings and sheets are frequently utilized as supports, insulating components, and gaskets in high-temperature, vacuum, MBE, and OLED areas.

-

Molecular beam epitaxy beam source crucible

One of the most significant epitaxial growth techniques for III-V and II-VI semiconductor crystals in the world is molecular beam epitaxy (MBE). The MBE process' ideal container for evaporating substances and elements is the PBN crucible.

-

OLED crucible

Almost everyone is familiar with OLED, which has recently become very popular. The iPhone 8 is rumored to have introduced OLED panels. The evaporation element container in the OLED production line is an OLED crucible.

Conclusion

Excellent electrical resistance and thermal conductivity are properties of PBN that make them ideal materials as heating elements. The range of possible applications for PBN heaters is growing, and some of these applications include highly functional PG/PBN heaters for semiconductor fields and CIGS-based thin films for photovoltaic energy production. Thank you for reading our article and we hope it can help you to have a better understanding of PBN heaters. Advanced Ceramic Materials (ACM) supplies high-quality ceramic powder and related products to meet our customers’ R&D and production needs. Please visit https://www.preciseceramic.com/ for more information.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}