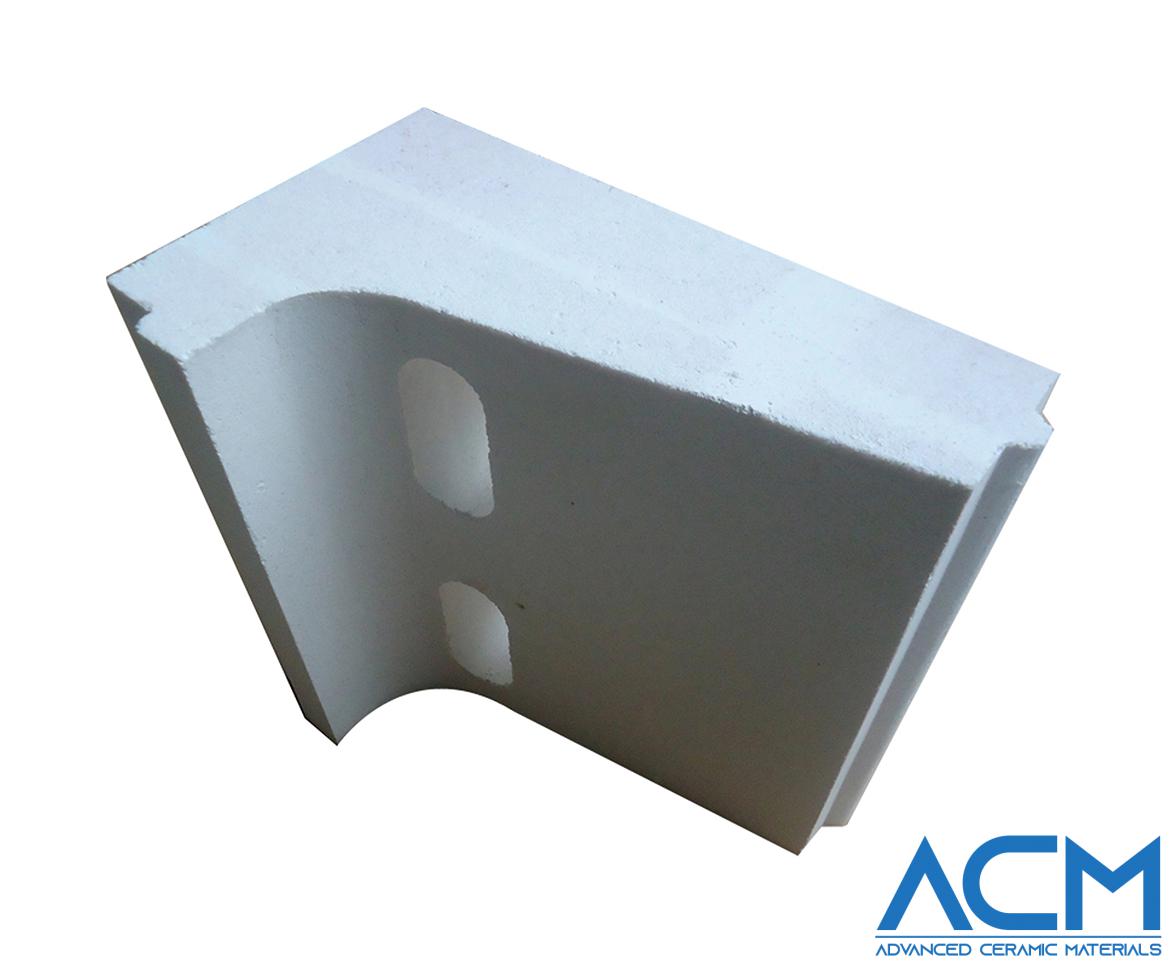

AC6253 Sintered Corundum Refractory Brick

- Catalog No. AC6253

- Material Al2O3, SiO2, Fe2O3

- Bulk Density 3 g/cm3

- Content 90%

- Max Working Temp. 1700℃

Inquiry

AC6253 Sintered Corundum Refractory Brick

Overview of Sintered Corundum Refractory Brick

Sintered Corundum Refractory Bricks are high-performance refractory materials, primarily composed of corundum (Al₂O₃) as the main crystalline phase. Known for their exceptional hardness, high melting point, and superior resistance to wear, corrosion, and extreme temperatures, these bricks are engineered for applications demanding durability under intense conditions. They are produced by sintering high-purity alumina at temperatures typically above 1,700°C, resulting in a dense, stable structure capable of withstanding severe environments.

Sintered Corundum Refractory Brick Specifications

|

Items |

Sintered corundum brick |

|

Al2O3% ≥ |

90 |

|

SiO2 % ≤ |

8 |

|

Fe2O3 % ≤ |

0.2 |

|

Bulk Density g/cm3 ≥ |

3 |

|

Apparent Porosity % ≤ |

18 |

|

Cold Crushing Strength Mpa ≥ |

100 |

|

0.2Mpa R.U.L ℃T 0.6 ≥ |

1700 |

Applications of Sintered Corundum Refractory Bricks

- Steel and Iron Furnaces: These bricks are essential in areas exposed to high temperatures and corrosive slags, including ladles, tundishes, and blast furnaces.

- Glass Furnaces: Ideal for high-temperature zones within glass furnaces, they resist heat effectively and minimize interaction with molten glass.

- Cement Kilns: Frequently applied in critical areas of cement kilns, where resistance to both heat and wear is crucial for long-term performance.

- Petrochemical Furnaces: Suitable for lining high-temperature reactors and furnaces in the petrochemical industry, providing strength and durability in challenging conditions.

Packaging and Handling

Our Sintered Corundum Refractory Bricks are carefully handled during storage and transportation to ensure they retain their original quality upon delivery.

Frequently Asked Questions (FAQs)

Q1: What is a Sintered Corundum Refractory Brick?

A Sintered Corundum Refractory Brick is a high-temperature-resistant brick made from corundum (Al₂O₃) as the primary crystalline phase. These bricks are known for their exceptional hardness, thermal stability, and corrosion resistance, making them suitable for intense industrial applications.

Q2: Where are Sintered Corundum Bricks typically used?

These bricks are extensively used in steel and iron furnaces, glass furnaces, cement kilns, and petrochemical reactors. They are ideal for environments that require extreme heat resistance, corrosion protection, and mechanical durability.

Q3: How do Sintered Corundum Bricks differ from other refractory bricks?

Sintered Corundum Bricks are characterized by their high alumina content (typically over 90%), providing exceptional hardness, low porosity, and superior resistance to acidic and basic slags. They offer enhanced durability, wear resistance, and corrosion protection compared to standard alumina or silica refractory bricks.

Request a Quote

-

Attachment (Optional)

No file chosen