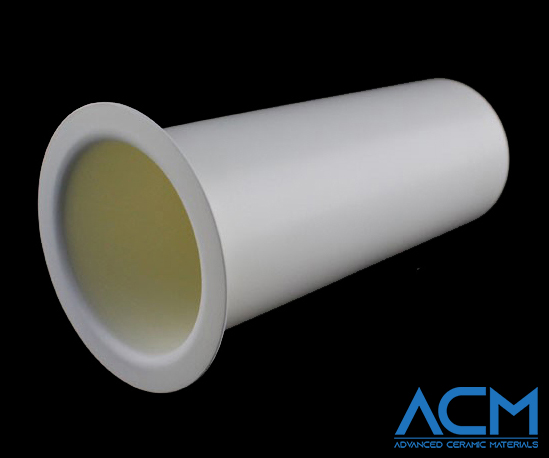

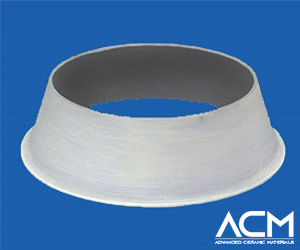

PBN0922 PBN Crucible, Pyrolytic Boron Nitride Crucible

- Catalog No. PBN0922

- Size 5ml~5L

- Material PBN, Pyrolytic Boron Nitride

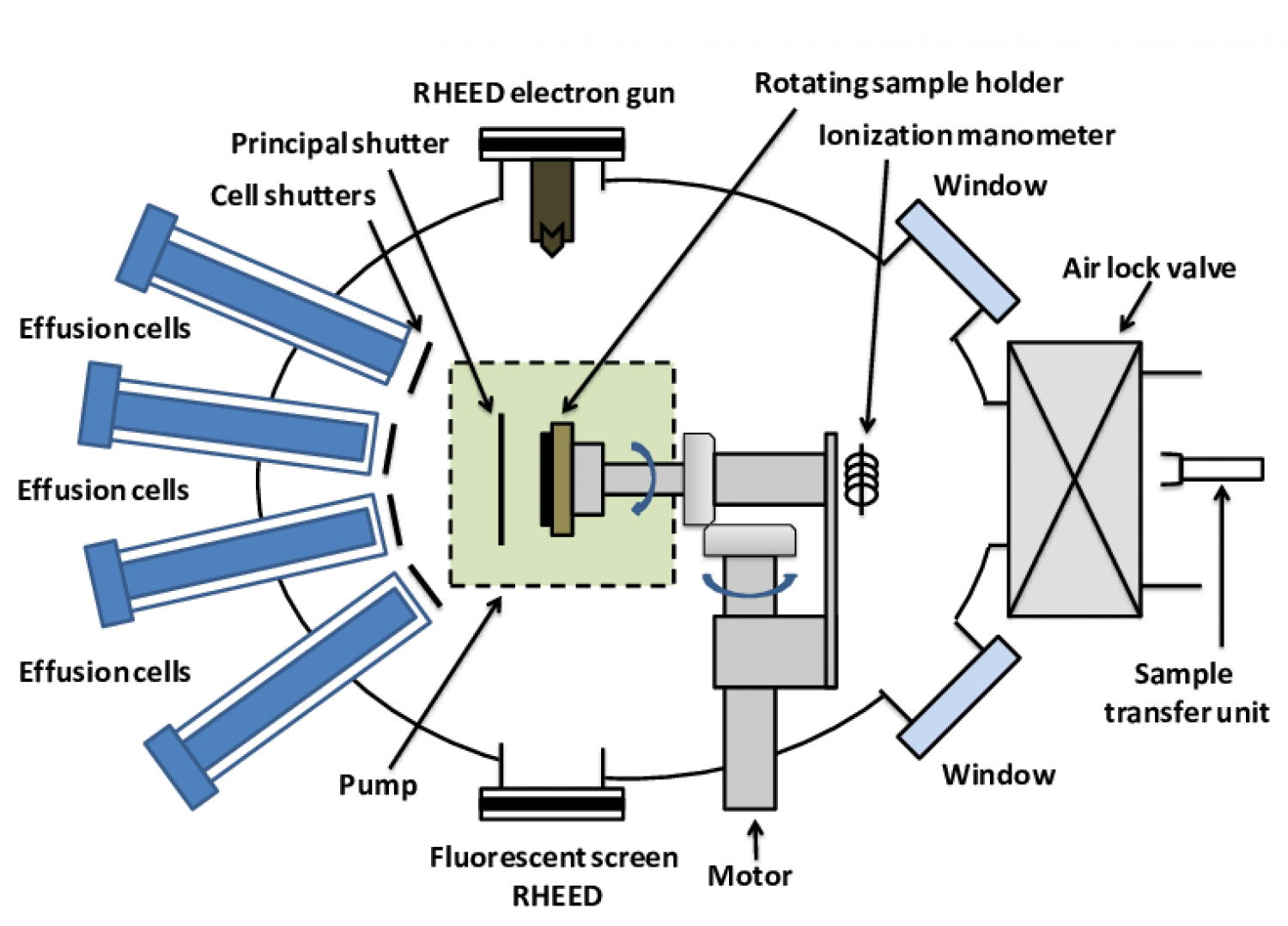

- Standard LEC, MBE, VGF

- Purity 99.99%

Datasheet

Inquiry

PBN0922 PBN Crucible, Pyrolytic Boron Nitride Crucible

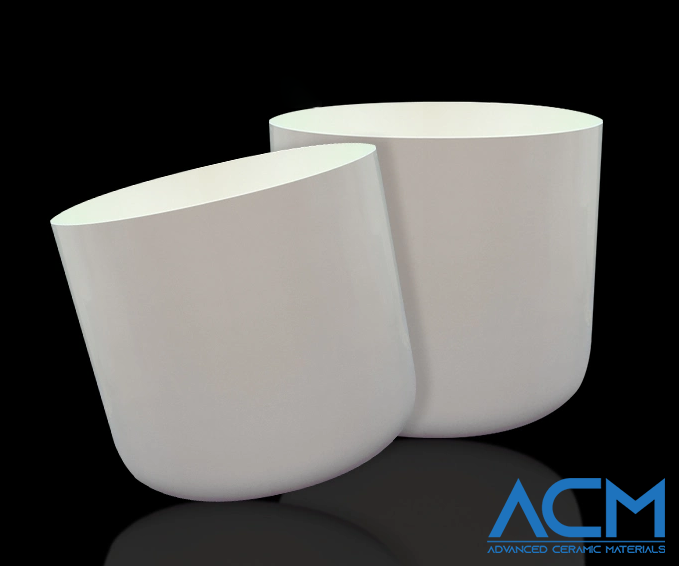

Pyrolytic Boron Nitride Crucible Description

Pyrolytic Boron Nitride (PBN) Crucible is a highly pure, crystalline form of boron nitride that is produced through a chemical vapor deposition (CVD) process. Compared with standard boron nitride ceramic, PBN crucibles offer significantly higher purity. These crucibles and other PBN products are synthesized directly on molds using the CVD process, involving BCl3 and NH3 at high temperatures and low pressures. This precise method results in PBN products with a total impurity content of less than 100 ppm, equating to a purity level exceeding 99.99%. Due to this exceptional purity, PBN crucibles are highly suitable for use in the semiconductor industry.

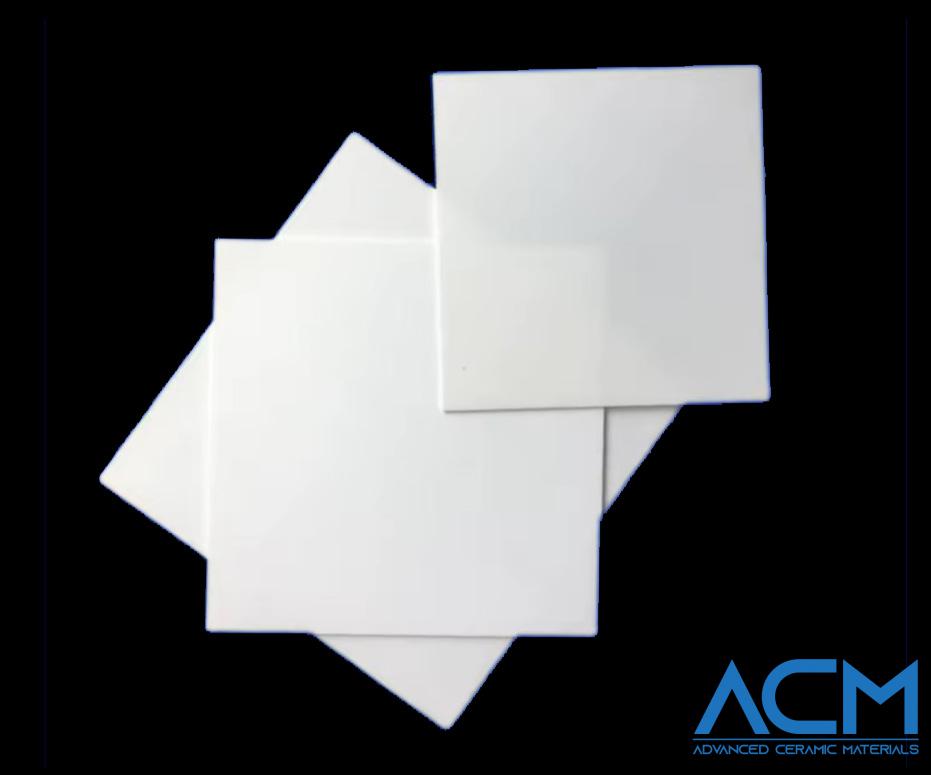

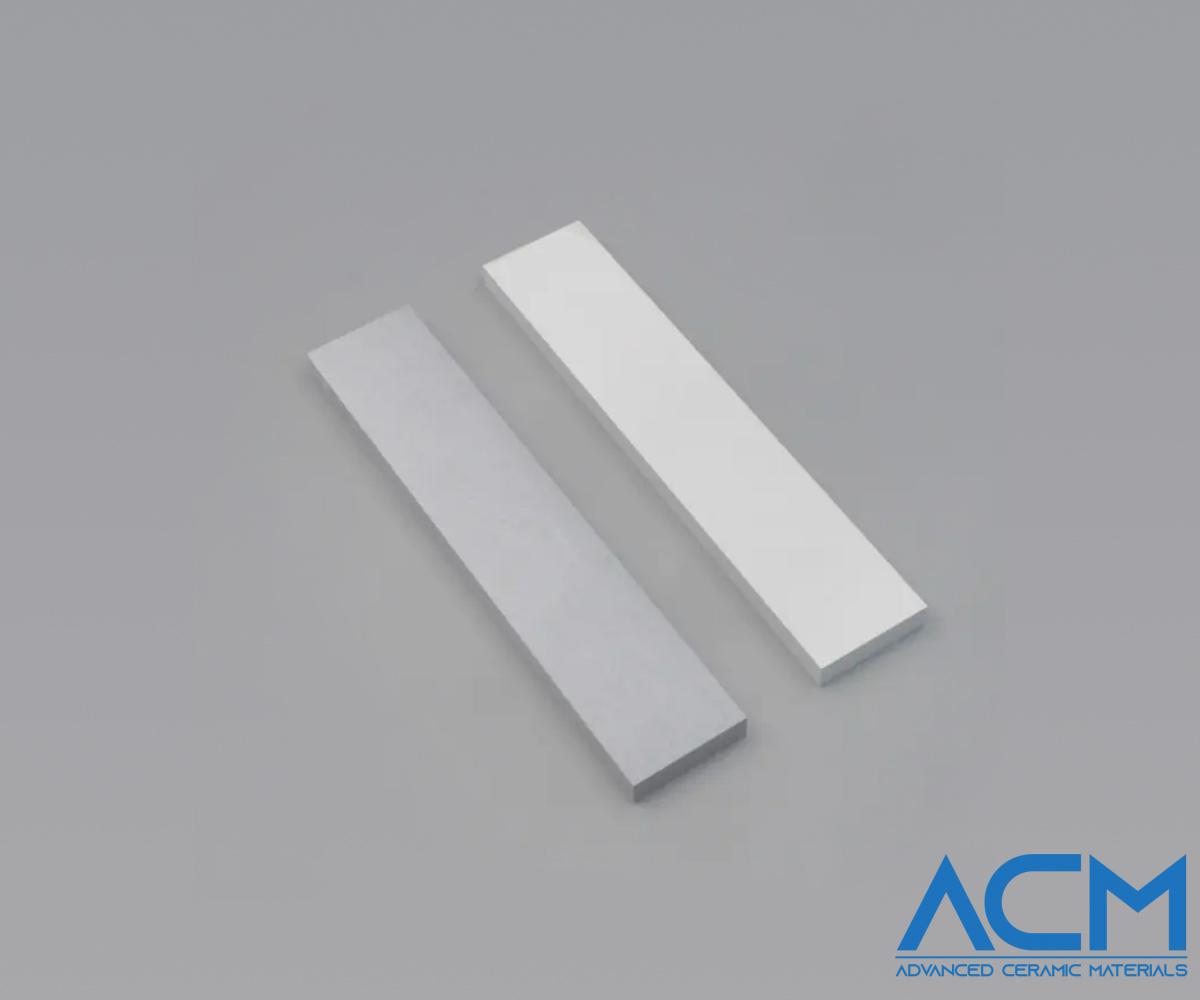

Boron nitride, like graphite, exhibits excellent strength at high temperatures. However, high-purity PBN products offer even superior mechanical properties. As the material is formed through the CVD process, the density of PBN products can approach theoretical maximum values. Additionally, PBN products from Advanced Ceramic Materials boast outstanding thermal shock resistance; PBN plates can be heated to over 2000 degrees Celsius and then plunged into water without fracturing.

Related: An Overview of Pyrolytic Boron Nitride (PBN)

Pyrolytic Boron Nitride Crucible Specification

| Product | Available size |

| Liquid Encapsulated Czochralski, PBN LEC crucibles | 50ml~5L |

| Molecular Beam Epitaxy, PBN MBE crucibles | 5ml~300ml |

| Vertical Gradient Freeze, PBN VGF crucibles | 0.2L~5L |

|

Item |

value |

Unit |

|

|

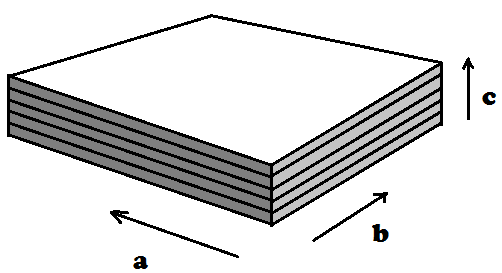

lattice constant |

a:2.504×10-10 c:6.692×10-10 |

μ m |

|

|

density |

2.0-2.19 |

g/cm3 |

|

|

resistivity |

3.11×1011 |

Ω·cm |

|

|

tensile strength(ab) |

153.86 |

N/mm2 |

|

|

bend strength |

c |

243.63 |

N/mm2 |

|

ab |

197.76 |

N/mm2 |

|

|

elastic modulus |

235690 |

N/mm2 |

|

|

thermal conductivity |

“a” direction “c” direction |

||

|

(200℃) |

60 2.60 |

W/m·k |

|

|

(900℃) |

43.70 2.80 |

W/m·k |

|

|

dielectric strength(at room temperature) |

56 |

KV/mm |

|

Pyrolytic Boron Nitride Crucible Applications

Pyrolytic Boron Nitride Crucible from Advanced Ceramic Materials (ACM) are essential in high-temperature and high-vacuum environments, where they excel due to their exceptional thermal conductivity, corrosion resistance, and electrical insulation properties. These crucibles are ideal for precise temperature control and safe handling of reactive materials, making them indispensable in semiconductor manufacturing, metal processing, and high-purity material synthesis.

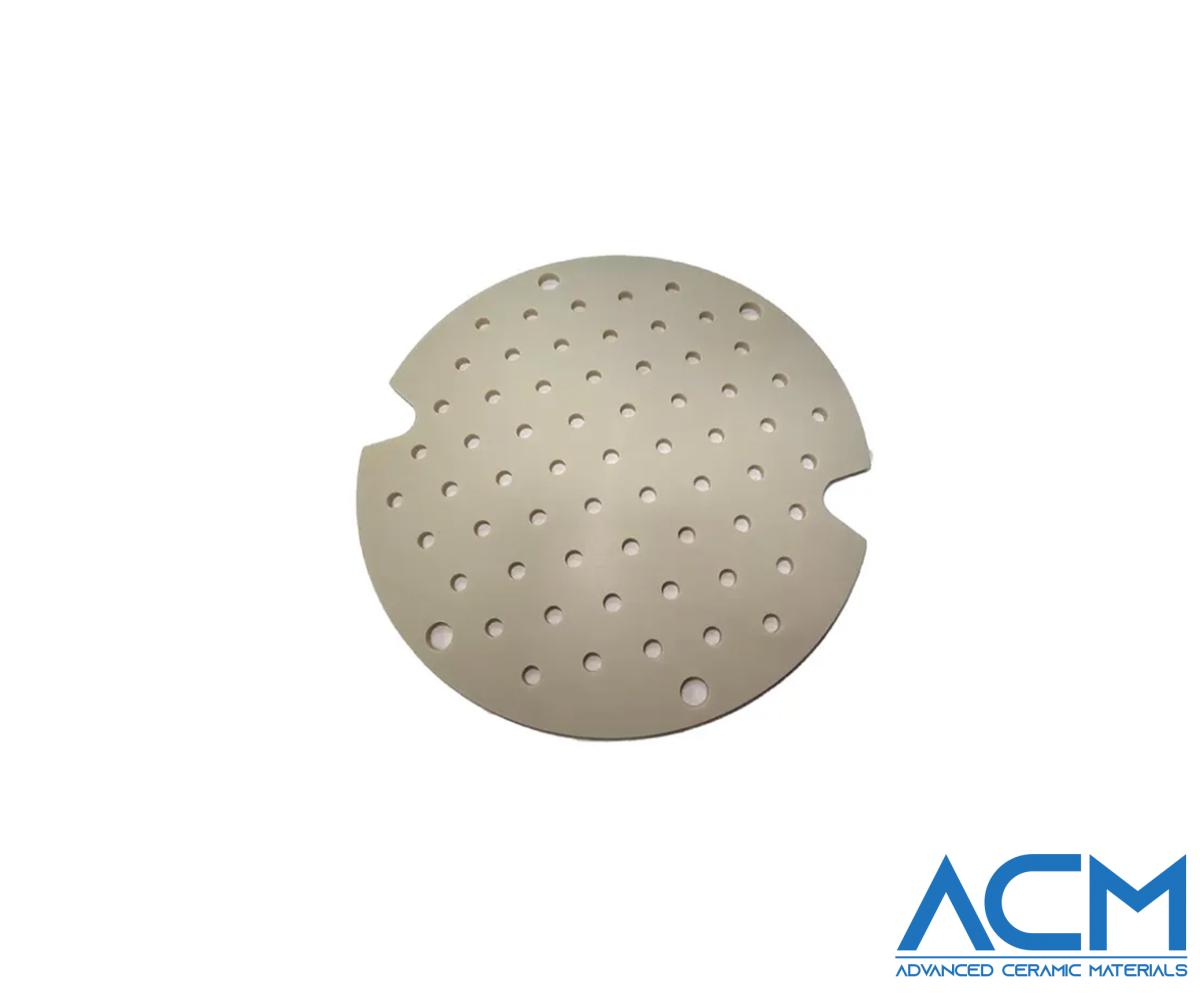

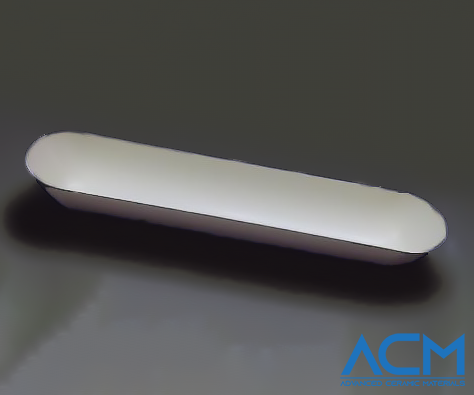

Available Pyrolytic Boron Nitride Crucible Products

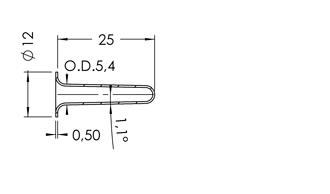

The PBN crucible product code is composed as follows:

Abbreviations and code:

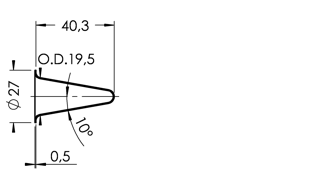

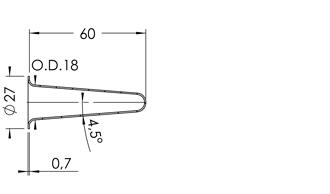

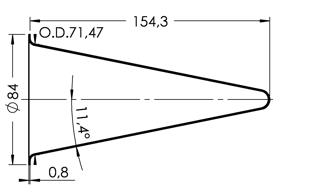

C conical-shaped crucibles

D double-wall crucibles

Ø lip

|

|

|

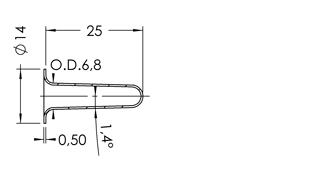

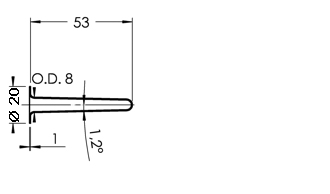

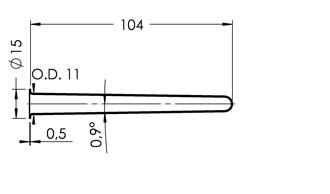

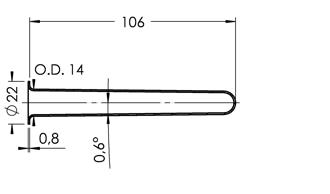

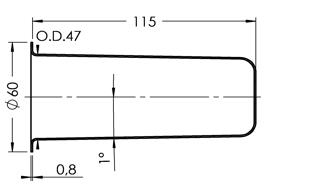

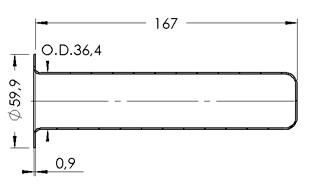

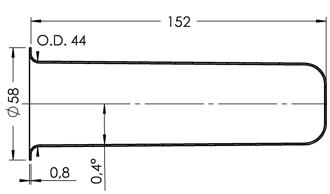

| Code: PBN 1-12 | Code: PBN 1-14 | Code: PBN 1-20 |

| Capacity:1 cm3 | Capacity:1 cm3 | Capacity: 1.5 cm3 |

|

|

|

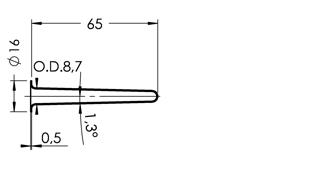

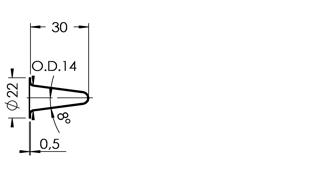

| Code: PBN 2-16 | Code: PBN C2-22 | |

| Capacity: 2cm3 | Capacity: 2 cm3 | |

|

|

|

| Code: PBN 5-16 | Code: PBN C5-27 | Code: PBN C5-29 |

| Capacity: 5 cm3 | Capacity: 5 cm3 | Capacity:5 cm3 |

|

|

|

| Code: PBN C8-27 | Code: PBN 10-22 | |

| Capacity: 8 cm3 | Capacity: 10 cm3 | |

|

|

|

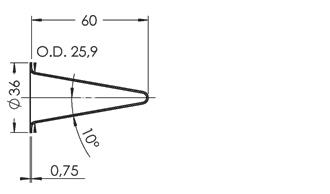

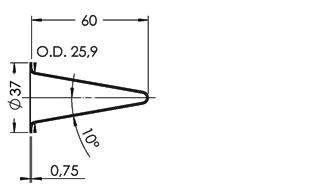

| Code: PBN C12-36 | Code: PBN C12-37 | Code: PBN C16-36 |

| Capacity: 12 cm3 | Capacity: 12 cm3 | Capacity: 16 cm3 |

|

|

|

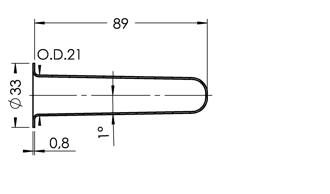

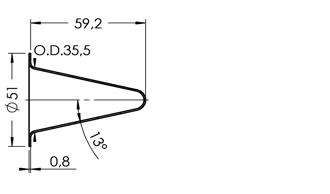

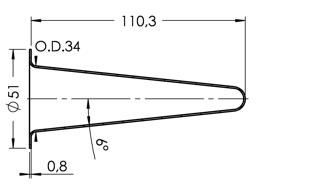

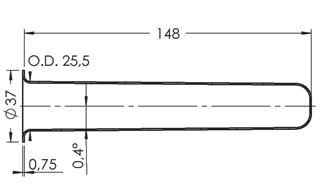

| Code: PBN C25-33 | Code: PBN C25-51 | Code: PBN 35-34 |

| Capacity: 25 cm3 | Capacity: 25 cm3 | Capacity: 35 cm3 |

|

|

|

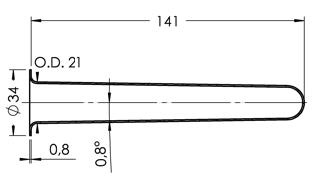

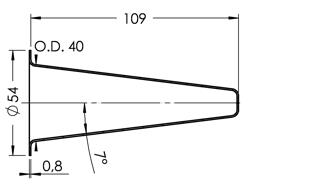

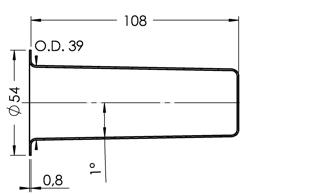

| Code: PBN C40-51 | Code: PBN C60-54 | Code: PBN60-37 |

| Capacity: 40 cm3 | Capacity: 60 cm3 | Capacity: 60cm3 |

|

|

|

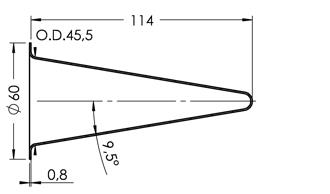

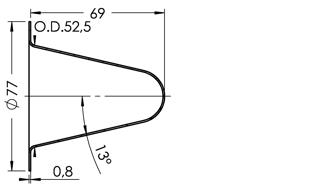

| Code: PBN C70-60 | Code: PBN C75-77 | |

| Capacity: 70 cm3 | Capacity: 75 cm3 | |

|

|

|

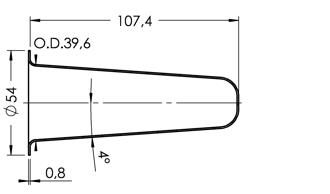

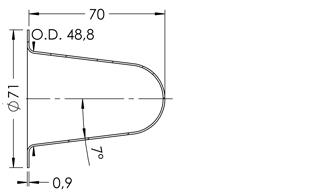

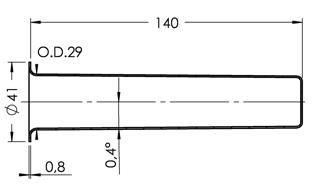

| Code: PBN C80-54 | Code: PBN C82-71 | Code: PBN 85-41 |

| Capacity: 80 cm3 | Capacity: 82 cm3 | Capacity : 85 cm3 |

|

|

|

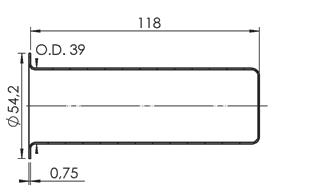

| Code: PBN 125-54 | Code: PBN 130-54 | |

| Capacity : 125 cm3 | Capacity: 130 cm3 | |

|

|

|

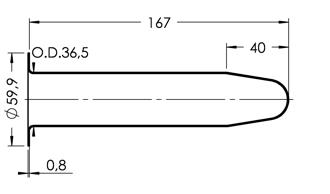

| Code: PBN 150-60 | Code: PBN 155-60 | Code: PBN 160-60 |

| Capacity: 150 cm3 | Capacity: 155 cm3 | Capacity: 160 cm3 |

|

|

|

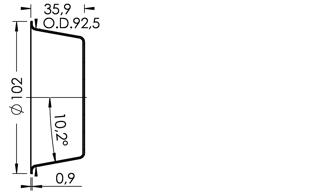

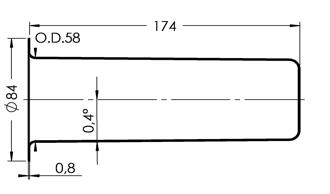

| Code: PBN C200-84 | Code: PBN 200-58 | Code: PBN 200-102 |

| Capacity: 200 cm3 | Capacity: 200 cm3 | Capacity : 200 cm3 |

|

||

| Code: PBN 420-84 | ||

| Capacity : 420 cm3 |

Packing Service

ACM’s 99.99% purity PBN Crucibles are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.