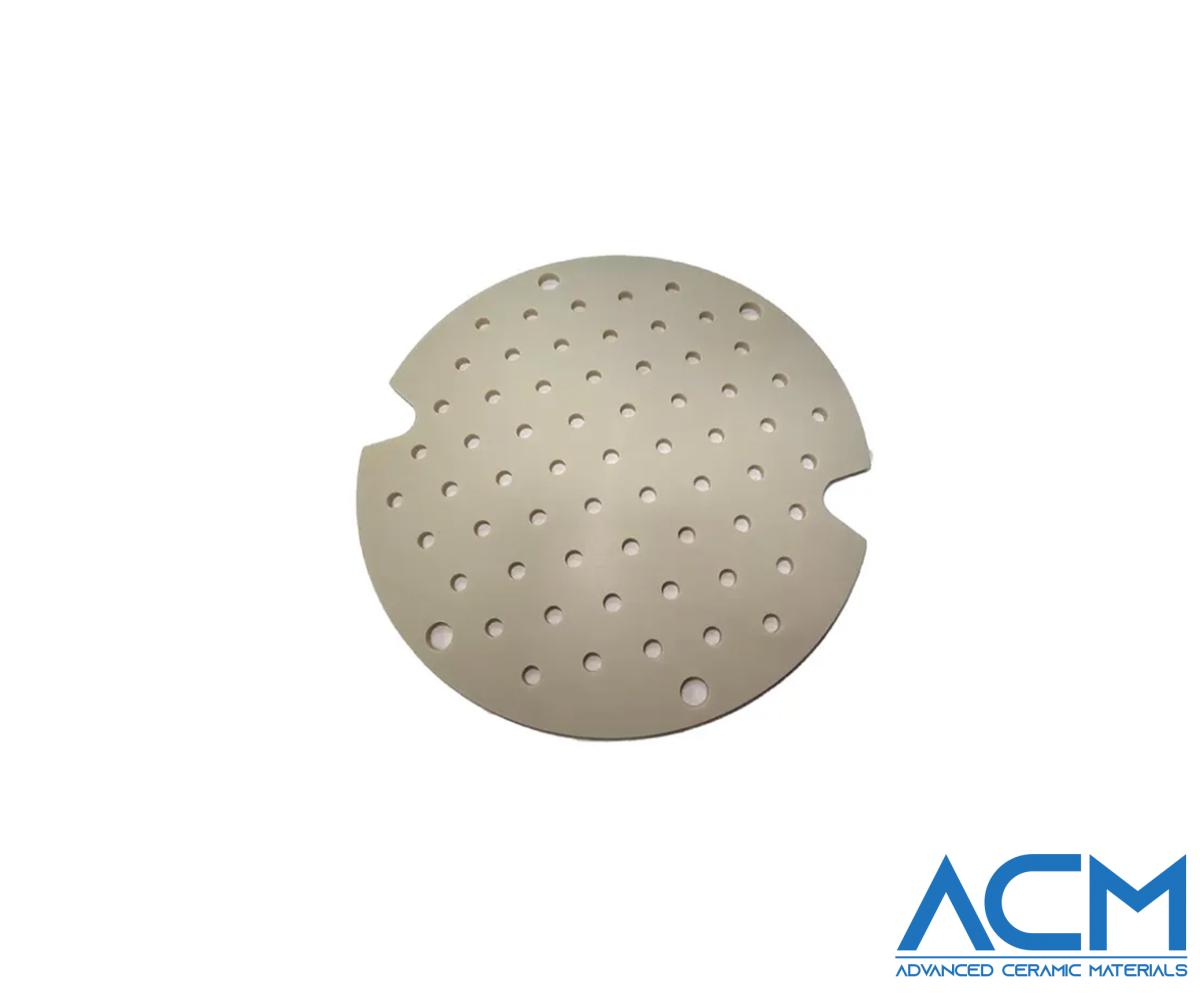

PBN0953 PBN Heater, Pyrolytic Boron Nitride Heaters

- Catalog No. PBN0953

- Size Diameter: 0.5"~4"

- Material PBN, Pyrolytic Boron Nitride, and PG Pyrolytic Graphite

- Purity 99.99%

- Color Black and White

Datasheet

Inquiry

PBN0953 PBN Heater, Pyrolytic Boron Nitride Heaters

PBN Heater Description

High-purity and high-performance Pyrolytic Boron Nitride (PBN) ceramics serve as the substrate for PBN heaters. In these heaters, a layer of Pyrolytic Graphite (PG) is applied to the surface of PBN plates via the Chemical Vapor Deposition (CVD) method, functioning as both a conductor and heating element. Depending on application requirements, the PG heating element can either be left exposed or covered with an additional layer of PBN.

Both PG and PBN boast exceptional purity levels (99.99% or higher) and are highly stable in vacuum or inert atmospheres. This makes the PBN-PG heating element extremely durable and capable of maintaining a clean chamber environment. These heaters can rapidly reach ultra-high temperatures of up to 1600°C without emitting any gas components, making them ideal for use in the semiconductor industry and other applications demanding high temperature, high vacuum, and high purity.

PBN Heater Specification

| Diameter: | 0.5"~4", or customized |

| Bulk Density | 2.0-2.19g/cm3 |

| Max. Working Temperature (vacuum) | 2400℃ |

| Volume Resistivity (Ω·cm) | 3.11*1011 |

| Flexural Strength (Mpa) | 243.63 |

| Thermal Conductivity (W/M·k) | 43-60 |

PBN Heater Advantages

- High Operating Temperature: PBN composite heating elements can operate at temperatures up to 1600°C.

- Mechanical Durability and Stability: These heaters offer high mechanical durability and excellent dimensional stability, even at elevated temperatures.

- Compact Design: The PBN layer provides electrical insulation while maintaining a compact and efficient design.

- Customizable Thermal Gradients: Thermal gradients can be tailored to meet specific application requirements, ensuring precise temperature control.

- Elimination of Outgassing and Contamination: PBN heaters minimize outgassing and contamination, making them ideal for ultra-clean environments.

- High Thermal Shock Resistance: PBN heaters exhibit exceptional resistance to thermal shock, allowing them to withstand rapid temperature changes without damage.

- Chemical Inertness: PBN is chemically inert to almost all metals, liquids, and gases, ensuring long-term reliability in various environments.

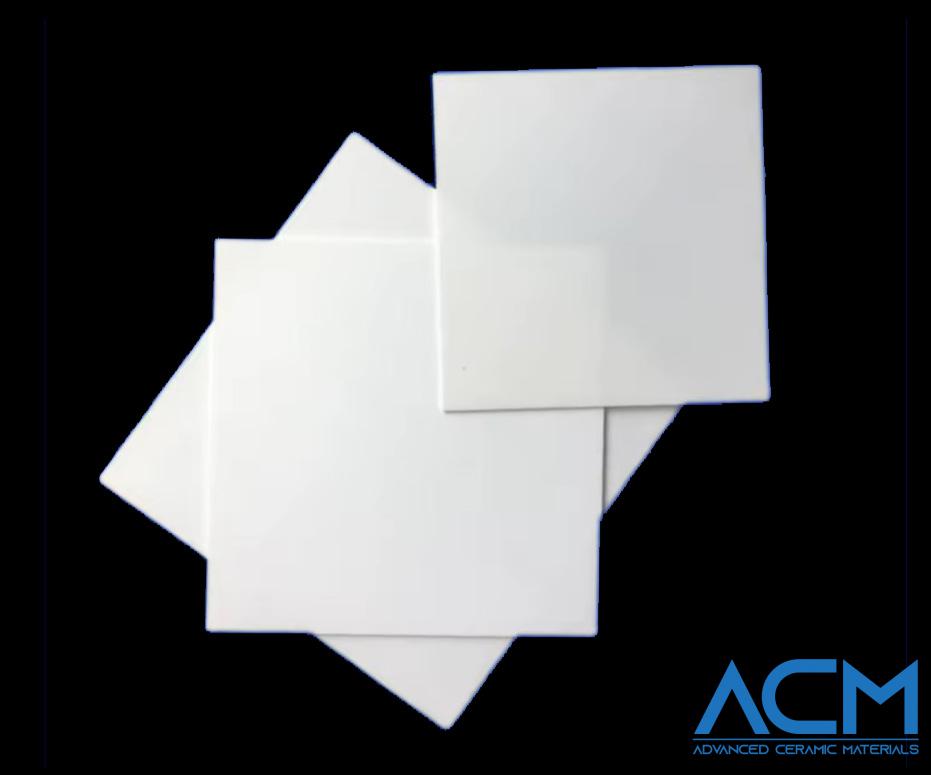

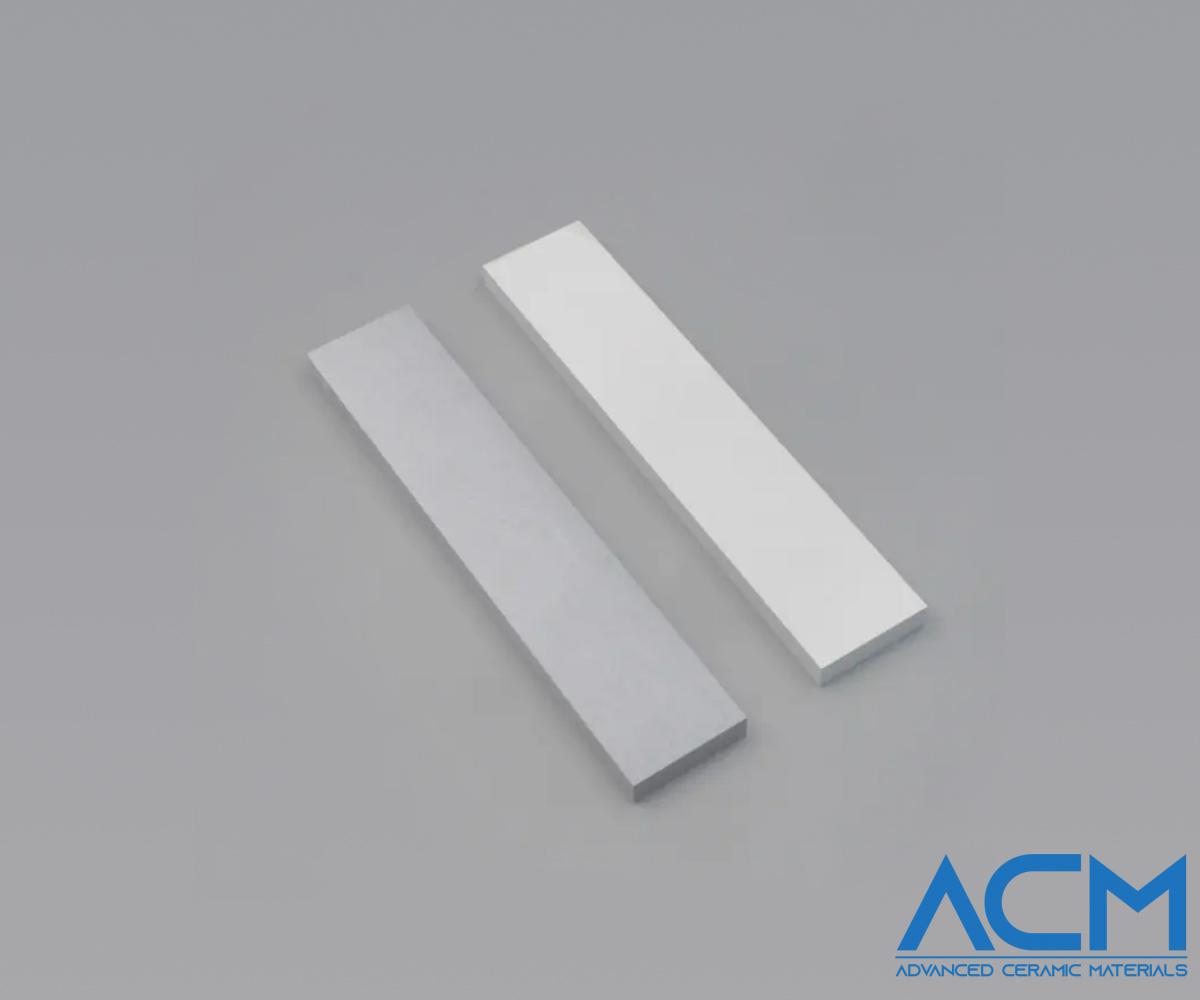

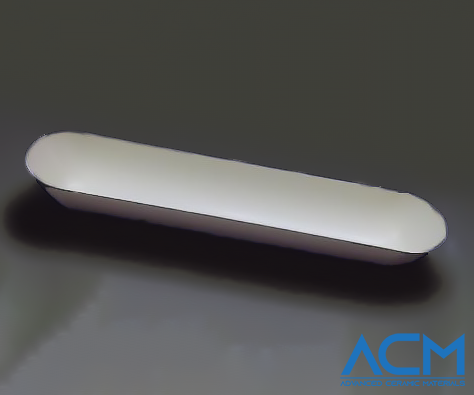

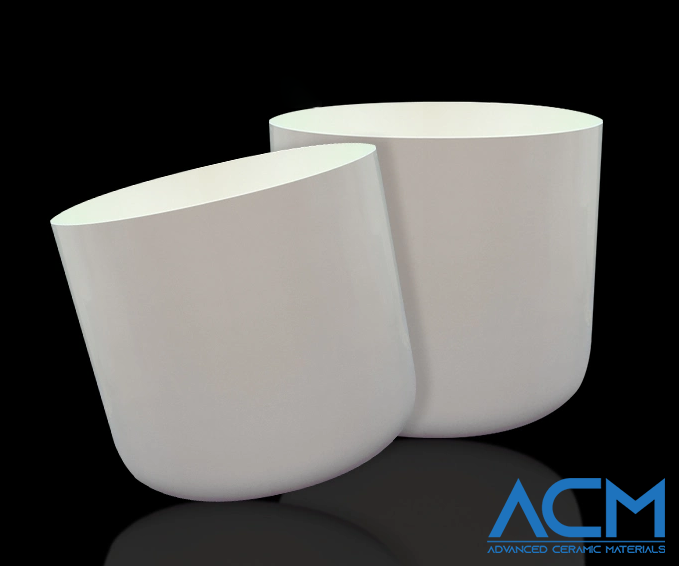

- Variety of Shapes: A large variety of Pyrolytic Graphite (PG) and PBN composite heater shapes are available to suit different applications.

PBN Heater Applications

PBN heaters from Advanced Ceramic Materials are highly valued for their purity, thermal stability, and chemical resistance, making them ideal for:

Semiconductor Manufacturing: Essential for processes like epitaxial growth and wafer processing in ultra-clean environments.

Molecular Beam Epitaxy (MBE): Provides uniform heating for precise thin film deposition.

High-Temperature Vacuum Furnaces: Used in annealing and material synthesis without contamination.

Chemical Vapor Deposition (CVD): Ensures consistent heating for high-quality coatings.

Crystal Growth: Delivers precise temperature control for producing single crystals.

Packing Service

ACM’s high-purity ceramic PBN heaters are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.