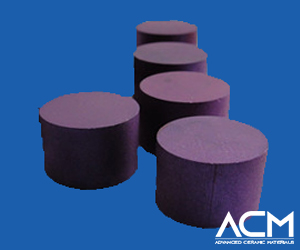

LA1413 Lanthanum Hexaboride Slab, LaB6 Tablet

- Catalog No. LA1413

- Molecular Formula LaB6

- Molecular Weight 203.78

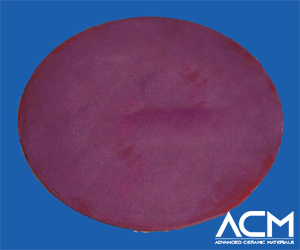

- Appearance Purple

- Melting Point 2210 °C

- Density 4.72 g/cm3

- Solubility in Water Insoluble

- Crystal Structure Cubic

Datasheet

Inquiry

LA1413 Lanthanum Hexaboride Slab, LaB6 Tablet

Lanthanum Hexaboride Slab Description

Lanthanum Boride, also called Lanthanum Hexaboride or LaB6, is a refractory ceramic material. It has a high melting point of 2210 °C, and is insoluble in water and hydrochloric acid. And it is stable in vacuum.

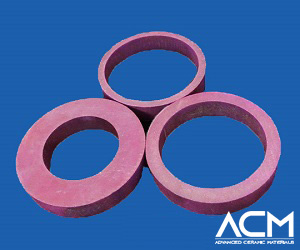

Borides are hard, high-melting materials with metal-like conductivity, and they are stable to nonoxidizing acids but break down in strong oxidizing agents and strong alkalis. Borides are used in semiconductors, superconductors, diamagnetic, paramagnetic, ferromagnetic, anti-ferromagnetic, turbine blades, and rocket nozzles. High Purity (99.999%) Lanthanum Boride Sputtering Target nanopowder forms may be considered.

Lanthanum Hexaboride Slab Specifications

| Product | Lanthanum Hexaboride | Structure | Polycrystalline |

| Symbol | LaB6 cathode | Thermal Conductive | 47 W/mK (20℃) |

| Cas No. | 12008-21-8 | Thermal Expansion | 6.2 10-6K-1 (20-900℃) |

| Atomic Mass | 203.78 g/mol | Electrical Resistance | ca.15 μΩ cm (20℃) |

| Density | 4.72 g/cm3 | Electrical Conductive | 6.65×104 S/cm (20℃) |

| Melting Point | 2528 K | Current Density | 150 A/cm2 (1950℃) |

| Hardness | 87.5 RA | Electron Emissivity | 2.6 eV |

| Flexure Strength (σ) | 200 Mpa | Fracture toughness (Kic) | 3.0 MN/m3/2 |

Lanthanum Hexaboride Slab Applications

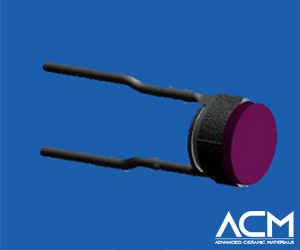

-Thermionic emission (cathode)

-Plasma source for plasma-enhanced coating(PECVD)

-Vacuum electron beam welding machine

-Electron beam surface reforming device

-Electron beam lithography device

-Transmission electron microscope

-Scanning electron microscope

-Surface analysis device

-Radio therapy devices

Packing Service

ACM’s Lanthanum Hexaboride Slab is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Request a Quote

-

Attachment (Optional)

No file chosen