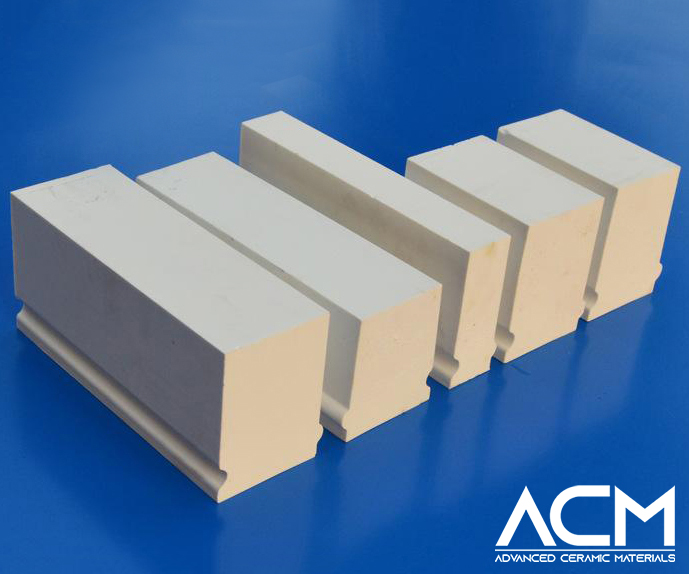

AC3937 Alumina Lining Brick

- Catalog No. AC3937

- Material Al2O3

- Purity 92%

- Shape Rectangle

- Size Customized

Datasheet

Inquiry

AC3937 Alumina Lining Brick

Alumina Lining Brick Descriptions

Alumina Lining Bricks are classified into three categories according to their shape: rectangular bricks, trapezoidal bricks, and irregular bricks. All of them are hard, dense, neat, and durable. Alumina grinding bricks have high mechanical strength and superb anti-corrosion properties. High alumina lining bricks are also called 92 ceramic lining bricks, ball mill high alumina lining, and microcrystalline wear-resistant high alumina ceramic lining bricks, molded by a two-way hydraulic press and sintered in the high-temperature natural gas kiln.

Alumina Lining Brick Specifications

Alumina lining brick products have the characteristics of high hardness, high density, low abrasion, good regularity, and corrosion resistance. Alumina bricks are used for wear-resistant linings of ball mills. Wear-resistant Alumina ceramic lining bricks can increase the service life of ball mill linings. Alumina grinding bricks can increase grinding space, and grinding efficiency, raise output by 30%-50% and reduce grinding time.

| Property | Value |

| Al2O3(%) | >92 |

| Bulk Density (g/cm3) | >3.6 |

| Hardness (mohs) | 9 |

| Wear Loss(%) | <0.01 |

| Color | White |

Alumina Lining Brick Features

-High mechanical strength

-Excellent abrasion

-Excellent impact resistance

-Corrosion and chemical resistance

-Lightweight

Alumina Lining Brick Applications

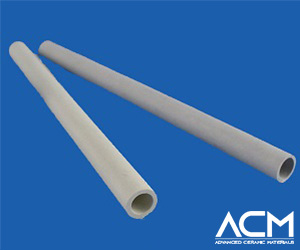

Utilized in industries such as pharmaceutics, cement, paint/pigments, chemicals, and coating, ceramic alumina lining bricks have a positive impact on the grinding process and production costs, and they're good for the environment as they lessen the usage of power and pollution. And it is widely used in ball mills and pipelines as wear-resistance lining.

Alumina Lining Brick Packaging

ACM’s alumina lining brick is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Request a Quote

-

Attachment (Optional)

No file chosen