AC0979 Alumina Custom Parts

- Catalog No. AC0979

- Material Al2O3

- Purity 95%, 96%, 99%, 99.5%, 99.7%, 99.8%

- Density 3.8~3.9 g/cm3

Datasheet

Inquiry

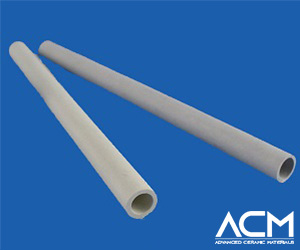

AC0979 Alumina Custom Parts

Alumina Custom Part Description

Alumina Custom Parts are made of aluminum oxide ceramics. Alumina is a ceramic material with high thermal conductivity, compressive strength, and thermal shock resistance. It also has a low thermal expansion, making it a suitable material for furnace use in the crucible, tube, and thermocouple sheath form. Aluminum oxide is high hardness and good wear resistance, making it a suitable material for ball valves, piston pumps, and deep drawing tools. In addition, it can be easily combined with metals and other ceramic materials using brazing techniques and metalizing.

Alumina Custom Part Specifications

| Composition | AL97 | AL98 |

| AL2O3 Content | 97% | 99.80% |

| Color | White | Ivory |

| Tensile | 30 Kpsi | 32 Kpsi |

| Flexural | 55 Kpsi | 60 Kpsi |

| Compressive | 300 Kpsi | 330 Kpsi |

| Density | 3.7 g/cc | 3.92 g/cc |

| Hardness | 13.8 HV, Gpa | 18 HV, Gpa |

| Thermal Conductivity | 25 W/(m K) | 32 W/(m K) |

| C.O.T.E. | 77 In / In°C (x10^7) | 78 In / In°C (x10^7) |

| Working Temperature | 1500 °C | 1750 °C |

| Dielectric Constant | 9.5 | 9.8 |

| Volume Resistivity | >10^14 Ohm-cm | >10^15 Ohm-cm |

| Dielectric Strength | 16 KV/mm | 20 KV/mm |

*This chart just demonstrates the typical properties of common alumina materials we use to produce our alumina ceramic parts. Please notice that the property for customized aluminum oxide parts could vary due to different processes. Advanced Ceramic Materials (ACM) is a specialized ceramics manufacturer, we could provide Al2O3 products produced under your specified instruction, or do our best to meet customers’ requirements.

Alumina Custom Part Applications

Alumina ceramic custom parts are used in the following applications:

Used for making parts for CVD, ion implants, photolithography, and semiconductor parts.

In traditional industries, alumina ceramics are ideal for products such as injector tubes, gas nozzles, and electrical insulators.

Used as a material for industrial furnaces due to its ability to maintain its hardness at high temperatures.

Used as a protector for high-temperature thermal couples.

Used as a material for the chemical industry due to its high corrosion resistance.

Packaging

Our Alumina Custom Part is carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.

Request a Quote

-

Attachment (Optional)

No file chosen