1700°C Furnace Inquiry: Why Alumina Tube Isn't Enough & How to Specify Correctly

Introduction

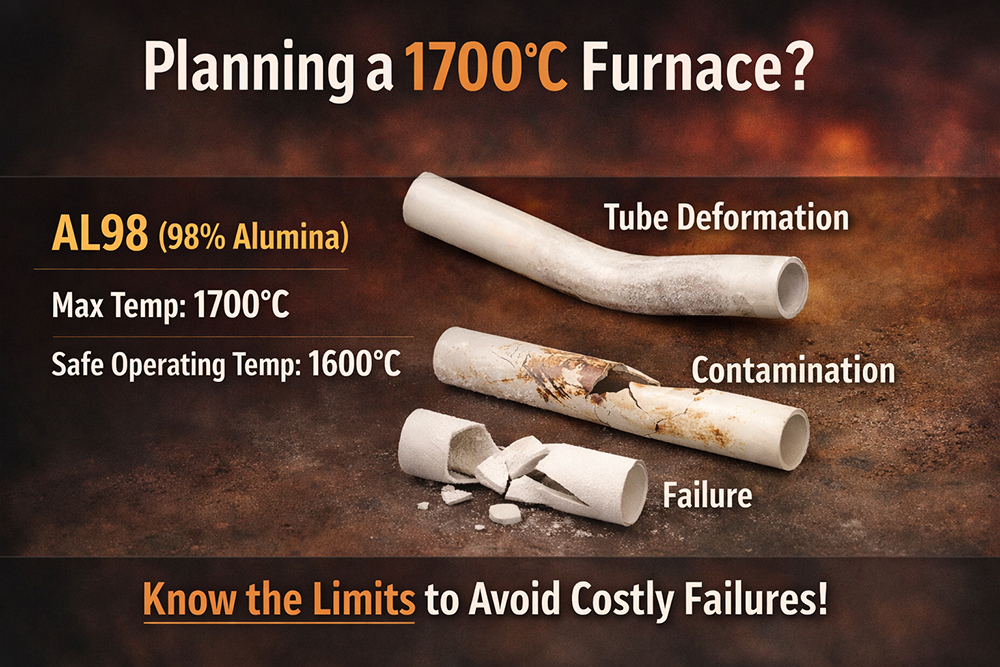

A recent inquiry from a research laboratory at a major U.S. university perfectly illustrates a common, critical oversight in high-temperature material selection. The researcher needed alumina tubes and insulation for a 1700°C furnace and initially referenced AL98 (98% purity). This scenario highlights the crucial gap between a material's absolute maximum temperature and its safe, long-term operating temperature. Selecting the wrong grade can lead to tube deformation, contamination, premature failure, and compromised experimental integrity.

The Misconception: Peak vs. Operational Temperature

Alumina ceramics are rated for temperature based on purity. However, a key distinction exists:

-

Short-Term Peak Withstand Temperature: The temperature at which the material will not immediately fail.

-

Recommended Long-Term Service Temperature: The temperature for safe, continuous operation with minimal creep, microstructural change, or property degradation over time.

For a 1700°C application, this distinction is everything. While high-purity alumina (≥99%) can be engineered for long-term service at this extreme, a standard 98% alumina tube operates at its absolute limit. Prolonged exposure risks:

-

Increased Creep: Gradual deformation under load.

-

Grain Growth & Porosity Changes: Weakening the mechanical structure.

-

Potential Contaminant Migration: Especially in critical atmospheres.

The Data-Driven Selection Guide

| Alumina Purity | Typical Long-Term Service Temp. Range (in air) | Suitability for 1700°C Continuous Use |

|---|---|---|

| 99.5% - 99.8% | Up to 1800°C+ | Excellent. Standard choice for extreme heat, superior stability. |

| 99.0% - 99.5% | Up to 1750°C | Good. A robust and often cost-effective solution for 1700°C. |

| ~98.0% (AL98) | Up to 1600-1650°C | Not Recommended. Too close to its limit; high risk of shortened lifespan and failure. |

Beyond Purity: Your 4-Point Specification Checklist

To ensure success, your specification must address these factors:

1. Operational Atmosphere

The "1700°C" requirement is meaningless without defining the environment.

-

Air / Oxidizing: Standard condition for most alumina.

-

Reducing / Hydrogen: Requires specific grades with controlled silica content to prevent reaction.

-

Vacuum: High-purity grades are essential to minimize outgassing and volatilization.

2. Thermal Profile & Mechanical Load

-

Thermal Shock Resistance: How fast will the furnace heat and cool? Rapid cycles demand formulations optimized for thermal shock, sometimes trading off a degree of ultimate temperature resistance.

-

Load-Bearing: Is the tube horizontal, acting as a muffle? Will it hold heavy samples? Mechanical strength at temperature must be calculated.

3. Geometry and Precision

-

Large Diameters / Thin Walls: More susceptible to sagging at temperature. Design and support become critical.

-

Dimensional Tolerance & Straightness: Essential for smooth sample movement and system integration.

4. Verifiable Manufacturer Data

Request material data sheets that specify:

-

Guaranteed chemical analysis (not just "99%+").

-

High-temperature flexural strength or creep data.

-

Bulk density and open porosity (affects insulation and gas tightness).

Conclusion & Actionable Next Steps

Specifying alumina for extreme temperatures is a systems engineering decision, not a commodity purchase. The goal is zero unscheduled downtime for valuable research or production.

For researchers and engineers designing around 1700°C, we recommend starting with 99% minimum purity alumina and then applying the checklist above.

To move forward with confidence:

-

Use our Specification Worksheet: This helps you compile all necessary parameters (Temperature, Atmosphere, Dimensions, Cycle Profile, etc.) for a complete technical review.

-

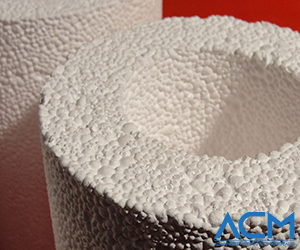

Consult for a Systems Approach: For furnace builds or retrofits, the synergy between the high-temperature tube and the alumina foam insulation is critical for efficiency and gradient control. We can review both components together.

Contact our engineering team with your completed worksheet or initial parameters. We will provide a technical assessment and product recommendations tailored to ensure the reliability of your high-temperature process.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments