PBN (CVD) Substrates: Benefits and Applications

Introduction

Pyrolytic Boron Nitride (PBN) substrates, produced using Chemical Vapor Deposition (CVD) techniques, have emerged as a cutting-edge material with a wide range of applications. These substrates possess unique thermal, electrical, and mechanical properties, making them valuable components in electronics, aerospace, semiconductor, energy, and other industries. In this article, we will explore the potential of PBN (CVD) substrates, their unique characteristics, and the diverse applications where they excel.

Figure 1. PBN Products

Understanding Pyrolytic Boron Nitride Substrates

PBN (CVD) substrates are thin layers of pyrolytic boron nitride deposited onto a substrate through a chemical vapor deposition process. The CVD technique enables precise control over the growth process, resulting in uniform and high-quality substrates. These substrates exhibit anisotropic properties, meaning they possess different physical properties along different crystallographic axes. This anisotropy allows for tailored functionality and performance in specific applications.

Related reading: What is Pyrolytic Boron Nitride (PBN)?

Benefits of Pyrolytic Boron Nitride Substrates

PBN (CVD) substrates are advanced materials with exceptional features. Their diverse benefits are listed as follows.

1. Thermal Stability:

The main strength of PBN (CVD) substrates is their remarkable thermal stability. They can withstand temperatures exceeding 1800°C in an inert atmosphere and up to 1400°C in an oxidizing environment without significant degradation.

Their low thermal expansion coefficient is another crucial characteristic. Unlike traditional materials, PBN substrates exhibit minimal expansion or contraction when exposed to thermal fluctuations, ensuring dimensional stability and minimizing the risk of thermal stress-induced failure.

2. Electrical Insulation:

PBN (CVD) substrates possess exceptional electrical insulation properties. They have high resistivity, low dielectric loss, and a wide bandgap, making them suitable for electrical isolation in high-power and high-frequency applications. PBN substrates can withstand high voltages and offer excellent electrical performance even at elevated temperatures.

3. Chemical Inertness:

PBN substrates exhibit excellent chemical inertness, remaining stable and unaffected by aggressive chemical environments. This resistance to chemical attack ensures the longevity and reliability of components and systems, making them highly suitable for applications in the chemical processing, semiconductor, and aerospace industries.

4. Mechanical Strength:

PBN substrates show remarkable mechanical strength and stability, allowing them to withstand mechanical stress and vibration. They have a high modulus of elasticity, which contributes to their dimensional stability and resistance to deformation. PBN substrates maintain their structural integrity under extreme conditions, making them suitable for applications that require robust materials.

Applications of Pyrolytic Boron Nitride Substrates

PBN (CVD) substrates find applications in a wide range of high-temperature technologies. Some notable examples include:

l High-Temperature Furnaces: These substrates serve as insulation components, heating elements, and support structures in high-temperature furnaces, enabling efficient and controlled heat transfer.

l Electronics: They are used as high-performance substrates for electronic components, such as high-frequency transistors, microwave devices, and optoelectronics. Their thermal conductivity and electrical insulation properties contribute to improved device performance and reliability.

l Semiconductor Industry: PBN substrates are utilized in semiconductor manufacturing, particularly in processes involving high temperatures and corrosive gases. They serve as chamber components, wafer carriers, and fixtures, providing thermal stability, chemical resistance, and electrical insulation.

l Aerospace: They play a crucial role in aerospace applications, including thermal management systems, radomes, rocket nozzles, heat shields, missile guidance systems, and satellite components. Their high thermal conductivity and mechanical stability enable efficient heat dissipation and protection in harsh environments.

l Energy and Power: PBN substrates find application in energy storage systems, such as lithium-ion batteries, where their thermal management capabilities and electrical insulation properties contribute to enhanced battery performance and safety.

l Optoelectronics: These substrates are used in optoelectronic devices, such as laser diodes and photonic components, where their dimensional stability and high-temperature performance are vital for precise optical alignment and long-term reliability.

Conclusion

In a word, PBN (CVD) substrates are revolutionizing various applications by offering exceptional thermal stability, electrical insulation, chemical inertness, and mechanical strength. Their diverse applications range from electronics to aerospace, from semiconductor manufacturing to energy. As technology continues to push the boundaries of what is possible, the demand for such materials will only increase. With their unique properties and ability to withstand extreme conditions, PBN substrates are driving innovation and opening new possibilities in high-temperature technologies. For more information about PBN ceramic materials, please visit Advanced Ceramic Materials (ACM).

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

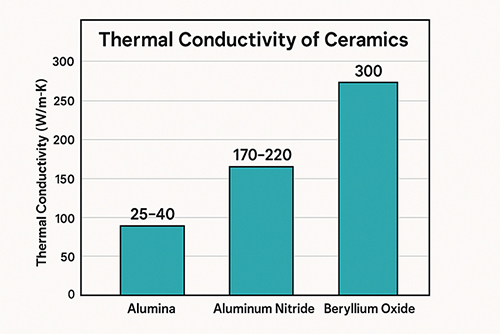

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity