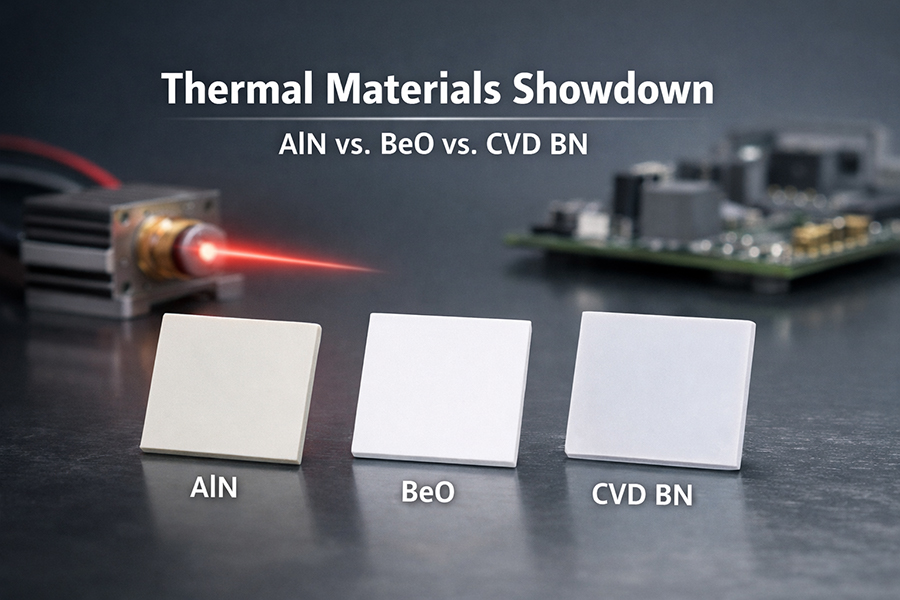

The Ultimate Performance Showdown of AlN, BeO & CVD BN Heat Spreaders

As laser diode power density climbs relentlessly, heat is no longer a byproduct—it's the chief adversary. Excess junction temperature directly steals performance: it causes wavelength drift, slashes wall-plug efficiency, and catastrophically shortens device lifetime. The battle for thermal management is won or lost at the material level. This analysis cuts through the marketing to deliver a performance-focused comparison of the three leading contenders: the well-balanced AlN, the toxic high-performer BeO, and the emerging isotropic champion, CVD BN. We'll provide a clear selection framework and translate material properties into real-world laser stability.

The High Cost of Heat in Laser Diode Performance

The relationship between temperature and performance in a laser diode is brutally non-linear. For every 10°C rise in junction temperature, expect a wavelength shift of approximately 0.3 nm, a drop in output power, and a potential halving of operational lifespan. In high-power arrays or single-emitter applications, inefficient heat spreading creates localized hotspots, leading to thermal lensing, mode instability, and accelerated catastrophic optical mirror damage (COMD). Effective thermal management is not an accessory; it is the foundational enabler of reliability, efficiency, and consistent output in demanding applications from industrial cutting and LiDAR to optical pumping.

The Material Contenders: Intrinsic Properties Under the Microscope

The ideal heat spreader combines high thermal conductivity, electrical insulation, and a thermal expansion coefficient (CTE) matched to common semiconductor materials. No single material excels perfectly in all, forcing a strategic trade-off.

Aluminum Nitride (AlN)

AlN is the default choice for a compelling reason: it offers an excellent balance. With a thermal conductivity ranging from 170 to 230 W/mK for high-grade ceramics, it effectively pulls heat away. Crucially, its CTE (~4.5 ppm/K) is a close match to gallium arsenide (GaAs), minimizing thermomechanical stress at the bond interface. It's electrically insulating, machinable, and, critically, non-toxic. Its limitation is its thermal conductivity ceiling, which can be a bottleneck for the very highest power densities.

Beryllium Oxide (BeO)

For decades, BeO was the benchmark, boasting a thermal conductivity (250-300 W/mK) that rivals some metals. However, its severe toxicity when inhaled as dust or fumes has rendered it a legacy material. Its use now triggers stringent handling protocols, escalating production costs, disposal complexities, and supply chain liability. While its performance is legendary, the operational and environmental risks have driven the industry to seek safer alternatives for all but the most niche, performance-at-all-costs applications.

Chemical Vapor Deposited Boron Nitride (CVD BN)

CVD BN represents a paradigm shift. Unlike hot-pressed BN, which has anisotropic (direction-dependent) properties, CVD BN is deposited to create a highly pure, isotropic structure. This gives it a unique combination: extremely high in-plane thermal conductivity (up to 400 W/mK), excellent electrical insulation, and natural lubricity. Its CTE is also well-matched to many semiconductors. As an ultra-pure, dense film on a manageable substrate, it offers unparalleled heat spreading in the X-Y plane, directly under the laser junction. The primary constraints are current cost and the specialized nature of its deposition process.

The Selection Decision Matrix

Choosing the right material is a function of application priorities. The following decision framework moves beyond datasheet numbers:

| Design Priority / Constraint | Recommended Primary Option | Key Rationale |

|---|---|---|

| Balanced Performance & Manufacturing | High-Purity Aluminum Nitride (AlN) | Offers the best compromise of high conductivity, good CTE match, ease of machining, and non-toxic, safe handling. Ideal for volume production. |

| Extreme Power Density (Military/Aerospace) | Beryllium Oxide (BeO) | Select only where its superior conductivity is absolutely critical and full toxic material containment protocols are established. A high-risk, last-resort option. |

| Maximum In-Plane Heat Spreading | CVD Boron Nitride on Substrate | Unmatched for dissipating heat laterally from a small, intense hotspot. Perfect for laser bars or where dielectric strength and thermal conductivity are paramount. |

| Cost-Sensitive & High Volume | Standard Aluminum Nitride | Provides reliable, good-performance thermal management without the premium of CVD BN or the hazard cost of BeO. |

Application Insight: Thermal Simulation Snapshot

A finite element analysis (FEA) simulation tells a clear story. For a 100W laser diode array:

-

Using a standard AlN substrate, the peak junction temperature might reach 85°C.

-

Switching to an optimized, high-conductivity AlN grade could lower this to 78°C.

- A design utilizing a CVD BN layer as an intermediate heat spreader could further reduce the hotspot to 70°C.

This 15°C differential isn't just a number; it can translate to a difference of thousands of operating hours in device lifetime and significantly improved power stability.

The ACM Proposition

At Advanced Ceramic Materials (ACM), we understand that you aren't just buying a piece of ceramic; you are procuring a critical thermal pathway that defines your laser's performance ceiling. Our value lies in providing not just the materials, but the application-specific insight. We supply meticulously characterized AlN ceramics across a range of conductivities, and we offer expertise on the integration of advanced solutions like CVD BN. Our goal is to help you navigate this material showdown with clear data, ensuring your selection optimally balances performance, reliability, and total cost of ownership.

Conclusion

The "thermal crisis" in high-power lasers is not insurmountable; it is addressable through intelligent material selection. By moving past generic assumptions and applying a disciplined, requirement-driven analysis of AlN, BeO, and CVD BN, engineers can transform a thermal management challenge into a competitive advantage in stability and longevity.

Ready to Optimize Your Laser's Thermal Path?

Contact ACM to submit your key laser parameters (power, wavelength, package type). Our engineering team will provide a tailored comparative analysis and material recommendation report to guide your next design toward peak thermal performance.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- 1700°C Furnace Inquiry: Why Alumina Tube Isn't Enough & How to Specify Correctly

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers