Key Benefits of Silicon Carbide Foam Filters in Iron Filtration Operations

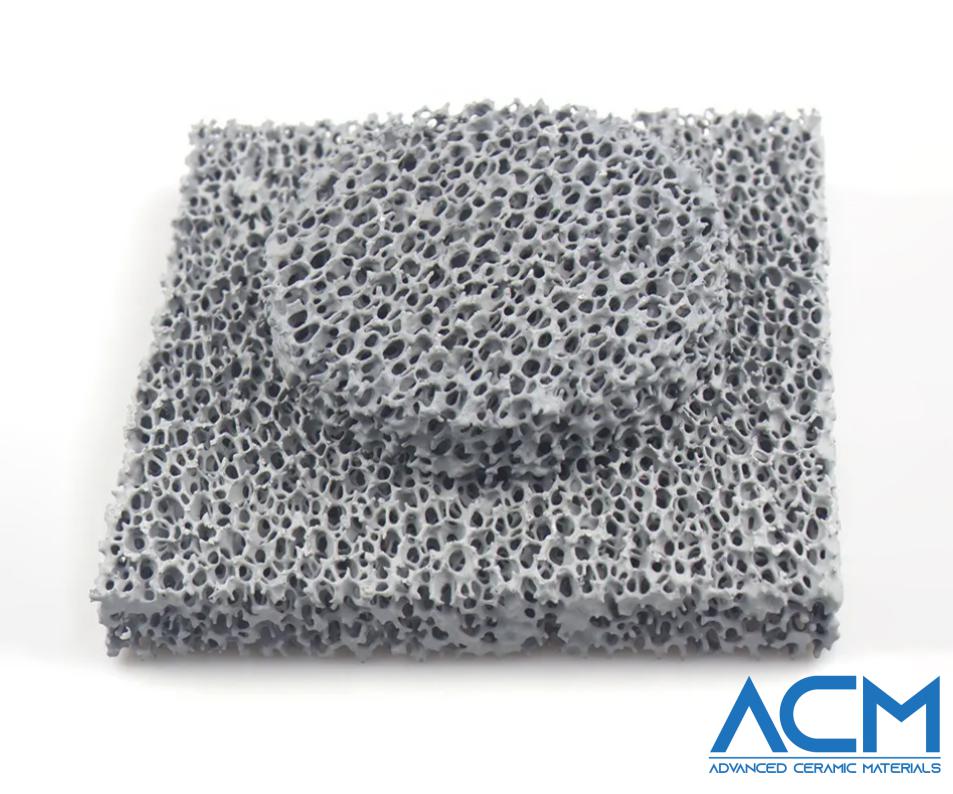

Silicon Carbide Ceramic Foam Filters are a type of advanced ceramic casting filter. They are made from silicon carbide (SiC), a material known for its excellent heat resistance and chemical stability. These filters have a porous texture that lets liquid metal pass through while trapping unwanted particles. Their design allows them to catch oxides, slag, and non-metallic inclusions during the casting process. With fewer impurities, castings become stronger and look cleaner. In simple words, these filters work like a sieve for molten metal, ensuring that only the good metal makes it into the mold.

When iron is molten and poured into a mold, it can pick up harmful bits that lead to defects. The unique structure of these silicon carbide filters helps reduce these issues. Compared with older methods, the foam filter provides a more natural and efficient filtration. It is similar to how a clean coffee filter leaves you with a smooth cup of coffee by removing grinds and oils. In foundries, having equipment that operates under high temperatures and constant mechanical stress is crucial. The heat-resistant nature of silicon carbide ensures that the filter retains its shape and function over many uses.

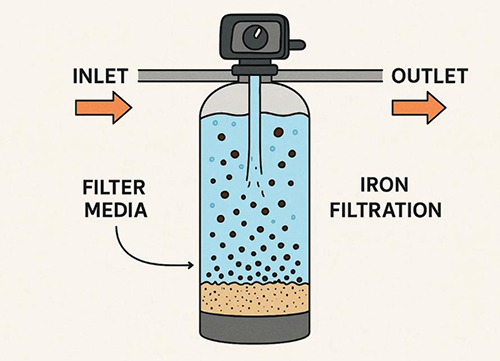

The Role of Silicon Carbide Foam Filters in Iron Filtration

In iron casting, the quality of the final product hinges on the purity of the molten metal. Silicon Carbide Ceramic Foam Filters help to improve this quality. They capture unwanted substances like oxides and slag before they can settle into the mold cavity. When the metal flows smoothly with fewer disturbances, it solidifies evenly. This results in castings that do not have cracks or weak spots.

For example, in a typical foundry operation, a steady and unbroken flow of molten iron results in castings with a better surface finish and stronger mechanical properties. Many seasoned engineers appreciate how the filter’s design minimizes turbulence in the metal stream. The reduced turbulence means there is less chance for contaminants to mix back into the cleaned metal. Over time, these benefits lead to better yields and less waste, which also helps lower overall production costs.

Advantages of Silicon Carbide Foam Filters over Other Iron Filtration Methods

Silicon Carbide Ceramic Foam Filters bring several advantages to the table. Here are some points that are often mentioned by professionals in the industry:

1. Improved Filtration Efficiency:

Compared to older techniques, these filters remove a wider range of impurities. The foam’s open structure offers ample surface area for trapping contaminants, leading to cleaner metal output.

2. Enhanced Casting Quality

With fewer inclusions in the molten metal, the resulting castings have fewer defects. This means that the final product is not only mechanically sound but also visually smooth.

3. Consistent Performance:

Many operators have noted that once these filters are in use, they provide consistent performance even under difficult casting conditions. Their ability to maintain a steady performance translates into stable production processes.

4. High Thermal Stability:

The material, silicon carbide, is known for its ability to withstand very high temperatures. This means that even during extreme casting operations, the filter does not easily degrade or deform.

5. Cost-Effective in the Long Run:

Although the initial investment might be higher, the filter’s durability and prolonged lifespan can result in lower maintenance and replacement costs. In practical cases, foundries have seen a decrease in overall operational expenses over time.

6. Versatility:

These filters work well with different types of iron, whether it is gray iron, ductile iron, or even steel. Their multi-use capability makes them a reliable asset in various casting environments.

To put it in everyday terms, imagine upgrading from an old, clogged strainer to a new, high-quality one. The new one saves you time cleaning up and gives you a better result each time you make a meal. That is very much the case with these foam filters when dealing with molten metal.

Conclusion

Silicon Carbide Ceramic Foam Filters have proven themselves to be a reliable solution in the realm of iron filtration. Their ability to remove impurities leads to castings that are not only stronger but also have a finer surface finish. Many experienced foundry operators have given their stamp of approval to these filters due to their consistent performance under high-temperature conditions.

The simple yet robust design of these filters means that over time, manufacturers enjoy consistent quality, lower maintenance costs, and fewer production hiccups. This is not just a trend, but a steady improvement in the way metal casting is done.

For every foundry looking to ensure high-quality castings and efficient operations, Silicon Carbide Ceramic Foam Filters are a wise investment. Materials for these superior filters are provided by Advanced Ceramic Materials (ACM), a trusted supplier known for their quality and performance in demanding industrial environments.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments