Benefits and Applications of Brazed Ceramis in Medical Devices

Introduction

Most medical devices need more than mere ceramic components to operate effectively. Sometimes, ceramics alone cannot meet the requirements of sensitive electronics that need to be shielded from water and other impurities. When we couple ceramics with metals via brazing, we have enclosures that protect as well as operate reliably in the long term. The process provides strong, air-tight, and biocompatible seals that have been tested and used in various devices utilized in the medical field.

Advantages of Brazed Ceramics

Improved Hermetic Sealing

When metals and ceramics are joined by brazing, a leak-free, strong seal is created. This moisture-free, gas-free, liquid-free seal prevents moisture, gases, and liquids that can harm the inner electronics of a medical device. It is a simple yet effective way of ensuring a device, such as an implant, will be reliable for decades. Normal wear and tear cannot easily break this seal, a seal that is crucial to patient safety.

Increased Durability

Ceramics inherently have strength and hardness, but they need a solid bond with metal in order to withstand physical stress. Brazing is an old technique that produces a solid joint between the two materials. This produces products that will survive the stresses of motion and pressure daily. Pacemakers or portable monitoring systems are just a couple of devices that impose different mechanical loads and would be enhanced by this solid assembly.

Biocompatibility

Among the major advantages of using ceramics is that they are kind in their interaction with the body. Implants made of these materials minimize the occurrence of adverse reactions when they come into contact with human tissue. Brazed bonds supplement this safety feature by offering a means to provide assurance that the joint union is not affected and any poisonous substances or elements are not deposited into the device. Patients may therefore enjoy a greater sense of safety for long periods.

Corrosion Resistance

Ceramics and proper metals used in brazing both offer superior corrosion resistance. This is especially important in the sometimes challenging environments of the body. Corrosion can slowly destroy a device, leading to unexpected failures. By using materials that offer corrosion resistance, engineers are able to create devices that maintain their shape and function for their entire lifetime.

Thermal Stability

Medical devices, especially those containing electronic parts, have a tendency to overheat. Ceramics naturally can withstand high temperatures, and their brazing with metal to form a union ensures there is no overheating. This union prevents overheating and increases the life of sensitive components. In either high-temperature procedures or routine day-to-day functions, these cases guarantee devices run securely and smoothly.

Applications in Modern Medical Devices

Cochlear Implants

Cochlear implants require precision electronic performance to operate sound efficiently. The brazed ceramic-to-metal feedthroughs enable hermetic sealing, enabling small bits of electronics to stay dry and free from the fluids of the body. Such predictability gives way to better performance and longer lifespan of the implant, which makes users more confident and achieves consistent results.

Cardiac Pacemakers

For a pacemaker to operate effectively, it must shield its internal circuitry against moisture and corrosive body fluids. Brazed ceramic housings produce rugged, protective coverings that shield sensitive electronics. Such sound containment isn't only critical for the device to function properly but also for patients whose lives are at risk with these systems.

Neurostimulators

Gadgets designed to aid in the management of chronic pain and movement disorders depend on stable and consistent electrical stimulation. By using ceramic cases brazed with metal, neurostimulators are provided with tight seals that protect their internal electronics. This shields against interference from body fluids or contaminants, allowing the device to precisely control nerve activity.

Implantable Drug Delivery Systems

Accuracy is the game when it comes to delivering medicine within the body. Implantable drug delivery mechanisms must have adequate seals to keep any leakage or contamination from occurring. Brazed metal-to-ceramic joints maintain the integrity of the dose-delivery mechanism, excluding contaminants and allowing for the precise delivery of the medication over many cycles of operation.

Endoscopic Equipment

Endoscopic devices usually need to endure harsh conditions when undertaking medical procedures. The high-quality nature of brazed ceramic-metal joints protects inner elements from exposure to fluids, dust, and other contaminating particles. This preserves endoscopic devices in their best state, guaranteeing clean and consistent performance despite the most demanding procedures.

Conclusion

Brazed ceramics have proven to be worthwhile assets in the medical device market. Their ability to provide excellent sealing, longevity, body tissue compatibility, corrosion resistance, and high-temperature capability renders them indispensable in modern technology. From cochlear implants to endoscopes, such robust and enduring cases are used in applications of a broad range. Physicians and engineers alike appreciate the way these instruments become stable and consistent performers despite adverse conditions.

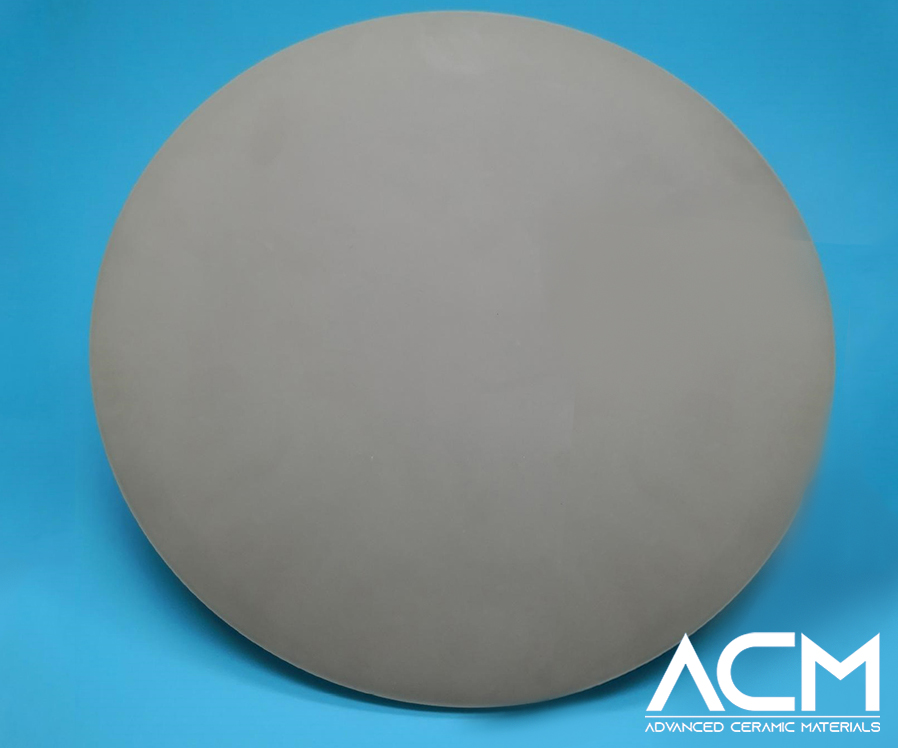

For trustworthy, high-quality materials, the majority of practitioners resort to Advanced Ceramic Materials (ACM) as their material source.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments