4H-SiC and 6H-SiC: What Are the Differences & How to Choose?

Introduction

Silicon Carbide (SiC) wafers are pivotal in the development of advanced electronics, heralding a new era of efficiency and performance. SiC wafers come in various polytypes, including 4H-SiC and 6H-SiC, each possessing unique properties that make them suitable for different applications. The choice between these polytypes is critical, as it directly influences device performance, durability, and efficiency.

Understanding the structural differences and application-specific advantages of 4H-SiC versus 6H-SiC is essential for engineers and designers to optimize their electronic systems. This guide aims to delineate these differences, providing insights on how to choose the right SiC polytype for your specific needs, thereby ensuring the highest levels of performance and reliability in semiconductor applications.

Here is a QUICK GUIDE for this article:

- Silicon Carbide Polytypes Overview

- 4H-SiC: Properties & Applications

- 6H-SiC Properties & Applications

- Comparative Analysis

- Selection Guide

SiC Polytypes Overview

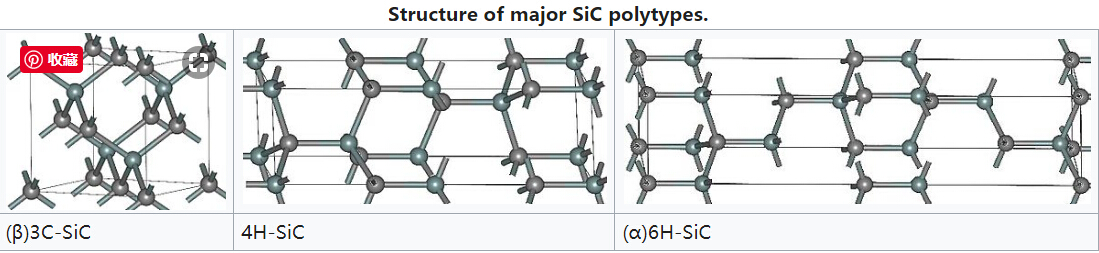

Silicon Carbide (SiC) distinguishes itself in the semiconductor industry through its varied polytypes, notably 4H-SiC and 6H-SiC. These polytypes are differentiated by their unique atomic arrangements, which significantly influence their respective physical and electronic properties, choosing between them is pivotal for specific semiconductor applications.

Structure of major SiC polytypes. Materialscientist at English Wikipedia, CC BY-SA 3.0 <https://creativecommons.org/licenses/by-sa/3.0>, via Wikimedia Commons

4H-SiC and 6H-SiC represent hexagonal crystal structures, with "H" indicating hexagonal symmetry and the numbers 4 and 6 the layers in their unit cells. This structural variation affects the material's electronic band structure, which is a key determinant of a semiconductor device's performance.

SiC crystals are typically produced using the Physical Vapor Transport (PVT) method, where a silicon and carbon source is sublimated in a high-temperature environment. Although both 4H-SiC and 6H-SiC can be grown under this method, varying the conditions such as temperature, pressure, and additives can promote the formation of one specific polytype over the other.

While 4H-SiC is often favored for power electronic applications due to its superior electronic properties, 6H-SiC is also valuable but tends to be selected for different uses. The choice between these polytypes is informed by their distinct advantages in electrical, thermal, and mechanical properties, which will be explored in more detail in subsequent sections.

Properties & Applications of 4H-SiC

4H-Silicon Carbide (4H-SiC) stands out as a superior polytype of SiC due to its wide bandgap, excellent thermal stability, and remarkable electrical and mechanical characteristics. These properties make 4H-SiC an ideal material for high-power and high-frequency applications, where performance and reliability at elevated temperatures and voltages are crucial.

4H-SiC structure with stacking sequence marked. User:Materialscientist, CC BY-SA 3.0 <https://creativecommons.org/licenses/by-sa/3.0>, via Wikimedia Commons

Electrical Properties: 4H-SiC's wide bandgap of approximately 3.2 eV at room temperature allows for devices that can operate at higher temperatures and voltages than those made from silicon. This wide bandgap also contributes to a high breakdown voltage, making 4H-SiC components ideal for high-power power electronics and high-frequency power devices. The material's low defect density, a result of the growth method, further enhances device performance by reducing leakage currents and increasing efficiency.

Thermal Properties: One of the most significant advantages of 4H-SiC is its high thermal conductivity, which is about three times that of silicon. This property enables effective heat dissipation, a critical factor in maintaining the stability and longevity of electronic devices under high power operations. Consequently, 4H-SiC is widely used in applications requiring efficient thermal management, such as power switches and aerospace electronics.

Mechanical Properties: 4H-SiC is also noted for its exceptional mechanical strength and hardness, which contribute to its resilience in harsh environments. These mechanical properties, combined with the material's thermal stability, make 4H-SiC suitable for high-temperature sensor devices and radiation-hard electronics, where conventional materials might fail.

Applications: The unique combination of electrical, thermal, and mechanical properties of 4H-SiC make it a preferred choice for a variety of applications. It is extensively used in high-power electronics for controlling and converting electric power efficiently, in high-temperature sensors that operate reliably in extreme environments, and in high-frequency power devices where superior performance is required. Additionally, its high thermal conductivity makes 4H-SiC an excellent substrate for the growth of other semiconductor materials, like Gallium Nitride (GaN), further broadening its application scope.

Table1. Properties and Applications of 4H-SiC

| Property | Description | Applications |

|---|---|---|

| Electrical | Wide bandgap (~3.2 eV), high breakdown voltage, low defect density. | High-power electronics, high-frequency power devices. |

| Thermal | High thermal conductivity (3x that of silicon), effective heat dissipation. | Power switches, aerospace electronics requiring efficient thermal management. |

| Mechanical | Exceptional mechanical strength and hardness, resilient in harsh environments. | High-temperature sensors, radiation-hard electronics. |

The exceptional characteristics of 4H-SiC, coupled with ongoing advancements in SiC technology, continue to drive its adoption in cutting-edge electronic and mechanical applications. Its ability to perform reliably under demanding conditions offers significant advantages over traditional materials, solidifying its position as a critical material in the advancement of high-power and high-frequency electronics.

Properties & Applications of 6H-SiC

6H-Silicon Carbide (6H-SiC), a distinguished polytype of SiC, showcases a wide bandgap, robust thermal stability, and impressive electrical and mechanical properties. These attributes render 6H-SiC particularly suitable for a spectrum of applications, from light-emitting devices to mechanical components where durability and performance are paramount.

6H-SiC structure with stacking sequence marked. User:Materialscientist, CC BY-SA 3.0 <https://creativecommons.org/licenses/by-sa/3.0>, via Wikimedia Commons

Electrical Properties: The wide bandgap characteristic of 6H-SiC, slightly larger than that of 4H-SiC, facilitates operation at high voltages and temperatures, surpassing the capabilities of traditional silicon devices. This quality, combined with a high breakdown voltage, positions 6H-SiC as an optimal choice for high-power electronics and high-frequency power devices. The polytype's hexagonal crystal structure, cultivated via the physical vapor transport method, ensures a low defect density, enhancing device efficiency and reducing leakage currents.

Thermal Properties: 6H-SiC's thermal conductivity, while excellent, varies slightly from 4H-SiC, yet it remains significantly higher than that of silicon, ensuring superior heat dissipation. This property is crucial for maintaining device integrity and performance under high operational stress, making 6H-SiC an invaluable material for applications requiring efficient thermal management.

Mechanical Properties: The inherent mechanical strength and hardness of 6H-SiC, akin to 4H-SiC, afford it resilience in harsh operational environments. Its robustness is particularly advantageous in high-temperature sensor devices and radiation-hard electronics, where material durability is critical.

Applications: 6H-SiC's unique electrical, thermal, and mechanical properties make it versatile across various sectors. It is predominantly utilized in high-power electronics for efficient electric power control and conversion, high-temperature sensors capable of withstanding extreme conditions, and high-frequency devices where performance is critical. Additionally, its compatibility as a substrate for other semiconductor materials, like Gallium Nitride (GaN), expands its application domain, further underscoring its utility in advanced electronic and mechanical systems.

Table2. Properties and Applications of 6H-SiC

| Property | Description | Applications |

|---|---|---|

| Electrical | Wide bandgap, high breakdown voltage, low defect density. | High-power electronics, high-frequency power devices. |

| Thermal | Superior heat dissipation, high thermal stability. | Power switches, aerospace electronics requiring efficient thermal management. |

| Mechanical | Robust mechanical strength and hardness, resilient in harsh environments. | High-temperature sensors, radiation-hard electronics. |

The pivotal characteristics of 6H-SiC, coupled with its polytype-specific advantages, continue to bolster its adoption in diverse and demanding applications. Its capacity to perform under stringent conditions offers considerable benefits over conventional materials, reinforcing its essential role in advancing high-power, high-frequency, and high-temperature electronics.

Comparative Analysis

When navigating the selection between 4H-SiC and 6H-SiC for semiconductor applications, understanding the nuanced differences between these two polytypes is essential. Both serve pivotal roles within the semiconductor industry, yet they cater to distinct application needs due to their inherent properties.

4H-SiC shines in high-power and high-frequency electronic devices. Its high electron mobility and saturation electron velocity enable efficient operation at elevated temperatures and voltages, making it a stalwart for power electronics. This includes applications like power switches, diodes, and rectifiers, particularly in sectors demanding robust performance under stress, such as electric vehicles (EVs), renewable energy systems, and aerospace electronics. The thermal conductivity of 4H-SiC, superior to that of many materials, facilitates exceptional heat dissipation, a critical aspect in maintaining device integrity and longevity.

6H-SiC, with its larger bandgap, lends itself effectively to light-emitting applications. It is a preferred choice for fabricating high-brightness LEDs and UV photodetectors, benefiting from the polytype's ability to operate efficiently in high-temperature environments. Beyond optoelectronics, 6H-SiC's mechanical properties, including high fracture toughness and resistance to wear and corrosion, render it suitable for mechanical applications. These range from cutting tools and bearings to turbine components, where durability and resistance to environmental stressors are paramount.

Table 3. Comparative Analysis: 4H-SiC vs. 6H-SiC

| Feature | 4H-SiC | 6H-SiC |

|---|---|---|

| Applications | High-power electronics, high-frequency power devices | Light-emitting devices, mechanical components |

| Advantages | High electron mobility, superior thermal conductivity | Larger bandgap, robust mechanical properties |

| Electrical | Power switches, diodes, rectifiers | LEDs, UV photodetectors |

| Thermal | Exceptional heat dissipation | Good thermal stability for high-temp operations |

| Mechanical | Durability under high stress | High fracture toughness, wear resistance |

The decision to opt for 4H-SiC or 6H-SiC hinges on several factors, primarily the application's specific demands for electrical, thermal, and mechanical performance. While 4H-SiC is the go-to for applications necessitating high-power density and thermal efficiency, 6H-SiC stands out in scenarios where light emission and mechanical resilience are key considerations.

Selection Guide

Selecting the appropriate SiC polytype—4H or 6H—requires a thorough understanding of the application's electrical, thermal, and mechanical requirements. This selection process is vital for optimizing performance and ensuring longevity in semiconductor devices.

For electrical requirements, consider whether the application demands high power and frequency. 4H-SiC, with its excellent electron mobility and saturation electron velocity, is ideal for power electronics used in EVs and renewable energy converters. Its capability to handle high voltages and frequencies efficiently makes it a superior choice for these applications.

In terms of thermal requirements, applications necessitating effective heat dissipation under high operational stress will benefit from 4H-SiC's remarkable thermal conductivity. This makes it especially suitable for power switches and other electronics in aerospace applications, where thermal management is crucial.

For mechanical requirements, evaluate the need for materials that can withstand harsh environments, including high temperatures and mechanical wear. 6H-SiC, with its robust mechanical properties and larger bandgap, excels in applications requiring high fracture toughness and resistance to wear, such as mechanical components and light-emitting devices.

In short, when choosing between 4H-SiC and 6H-SiC:

- Opt for 4H-SiC for high-power and high-frequency electronics where thermal management is critical.

- Choose 6H-SiC for applications prioritizing light emission and mechanical durability, including LEDs and mechanical components.

Table 4. Selection Guide: 4H-SiC vs. 6H-SiC

| Requirement | 4H-SiC Recommendation | 6H-SiC Recommendation |

|---|---|---|

| Electrical | High-power, high-frequency applications | Efficient light emission |

| Thermal | Applications requiring efficient heat management | High-temperature environments |

| Mechanical | Durability under high stress | High toughness, wear, and corrosion resistance |

Understanding these distinctions and aligning them with your application's specific needs will guide you in selecting the most suitable SiC polytype, thereby ensuring optimal device performance and reliability.

Conclusion

Understanding the differences between 4H-SiC and 6H-SiC silicon carbide polytypes is crucial for selecting the most suitable material for specific semiconductor applications. Each polytype offers distinct advantages: 4H-SiC excels in high-power and high-frequency electronic devices due to its excellent electrical and thermal properties, making it ideal for sectors such as electric vehicles and aerospace. In contrast, 6H-SiC, with its larger bandgap and superior mechanical properties, is better suited for light-emitting applications and durable mechanical components.

Making an informed decision between these two polytypes ensures optimal performance and reliability of the application, leveraging the unique benefits of each to meet specific operational requirements. Suppliers like Advanced Ceramic Materials (ACM) provide a range of SiC polytypes, supporting engineers and researchers in accessing the right materials for their projects without overtly promoting a specific product, but rather, emphasizing the importance of informed material selection.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments