ZSBN Ceramic: The Ultimate Composite Material

In the world of advanced ceramics, ZSBN ceramic stands out as a remarkable composite material. Combining the unique properties of Zirconium Diboride (ZrB2) and Silicon Nitride (Si3N4), ZSBN ceramic exhibits exceptional performance in various demanding applications. This article delves into the key features, applications, and benefits of ZSBN ceramic, highlighting why it is the ultimate choice for many industries.

Figure 1. ZSBN Nozzles

What is ZSBN Ceramic?

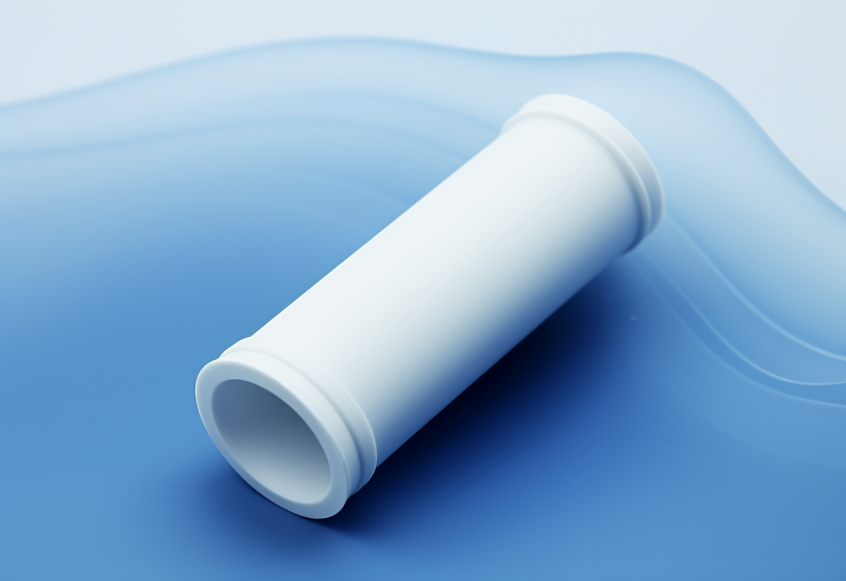

ZSBN ceramic, short for Zirconium Silicate Boron Nitride, is a composite material that integrates Zirconium Silicate (ZrSiO4) with Boron Nitride (BN). This combination results in a material that possesses high thermal stability, excellent electrical insulation, and remarkable mechanical strength. ZSBN ceramic is engineered to perform under extreme conditions, making it an ideal choice for a variety of applications.

Key Properties of ZSBN Ceramic

ZSBN ceramic is an advanced composite with unique features. It is composed of boron nitride, silicon carbide, and zirconium oxide to enhance its hardness and wear resistance. It also stands out for high thermal shock resistance, good chemical stability, and great dielectric strength.

1. Exceptional Thermal Stability:

With a high decomposition temperature and low thermal expansion coefficient, ZSBN ceramic remains stable and maintains its integrity even in harsh thermal environments. This makes it an ideal material for applications that involve rapid heating and cooling cycles, such as thermal management systems, high-temperature furnace components, and aerospace propulsion systems.

2. Excellent Thermal Conductivity:

Another key thermal advantage of ZSBN ceramic is its high thermal conductivity. Compared to traditional ceramic materials, ZSBN ceramic exhibits superior heat transfer capabilities. So, it could dissipate thermal energy efficiently and becomes an excellent choice for heat sinks, thermally conductive substrates, and electronic packaging. The enhanced thermal conductivity of ZSBN ceramic contributes to improved performance, reliability, and longevity of high-temperature devices and systems as well.

3. Outstanding Electrical Insulation:

ZSBN ceramic demonstrates excellent electrical insulation properties, making it well-suited for electrical and electronic applications in high-temperature environments. Its low electrical conductivity prevents electrical leakage and ensures the reliable operation of electrical systems. ZSBN ceramic is widely used in applications such as high-temperature electrical insulators, electrical connectors, and power electronics components.

4. Corrosion Resistance:

ZSBN ceramic exhibits exceptional resistance to chemical corrosion and chemical stability because of the presence of zirconia (Zr2O3). Thus, it is commonly employed in chemical processing equipment, corrosion-resistant coatings, and components exposed to corrosive gases or liquids to withstand harsh aggressive chemical environments.

5. Mechanical Strength and Wear Resistance:

As a ceramic composite, ZSBN ceramic possesses remarkable mechanical strength and wear resistance. So, ZSBN ceramic finds use in wear-resistant components, cutting tools, and high-temperature bearings, contributing to the durability and performance of machinery and equipment in demanding industrial settings.

Related reading: ZSBN Nozzles Used in Molten Metal Atomization

Applications of ZSBN (BN-45%, Zr2O3 45%)

ZSBN ceramic's unique combination of thermal stability, electrical insulation, and chemical resistance makes it suitable for a wide range of demanding applications.

1. Aerospace Applications:

The aerospace industry demands materials that can withstand extreme conditions while maintaining high performance. ZSBN meets these requirements with exceptional thermal stability and resistance to high temperatures. It is used in components such as engine parts, thermal barriers, heat shields, and rocket nozzles.

2. Automotive Applications:

In the automotive industry, ZSBN ceramic finds use in exhaust systems, catalytic converters, and engine components. Thanks to its thermal stability and resistance to corrosion, it could withstand the harsh conditions encountered in automotive environments. ZSBN ceramic also contributes to the overall performance and durability of automotive systems.

3. Chemical Processing:

ZSBN ceramic's resistance to chemical attack and corrosion makes it popular in chemical processing and petrochemical industries. It is employed in reaction vessels, crucibles, and other equipment used in chemical synthesis and processing. ZSBN ceramic's excellent chemical resistance ensures the integrity and longevity of equipment, reducing the risk of contamination and improving operational efficiency in these industries.

4. Electronics Industry:

ZSBN ceramic finds extensive use in the electronic industry due to its excellent electrical insulation capabilities and thermal management properties. It is employed in heat sinks, ceramic substrates, and insulating layers in electronic devices. ZSBN ceramic's efficient heat dissipation characteristics maintain lower operating temperatures for electronic components, and its electrical insulation properties ensure reliable operation and protect against electrical short circuits.

5. Energy Sector:

In the energy sector, ZSBN ceramic is utilized in thermal management systems, heat exchangers, and power generation equipment. ZSBN ceramic's high thermal conductivity allows for efficient heat dissipation. Additionally, its electrical insulation properties make it suitable for electrical connectors, insulating substrates, and other electrical components in power generation and distribution systems.

Advantages of ZSBN Ceramic Over Other Materials

Compared to other advanced ceramics, ZSBN ceramic offers several advantages:

- Enhanced Performance: The combination of Zirconium Silicate and Boron Nitride results in a material that performs better under extreme conditions compared to single-phase ceramics.

- Versatility: ZSBN ceramic can be tailored to meet specific application requirements, offering flexibility in its use across different industries.

- Cost-Effective: Despite its superior properties, ZSBN ceramic is relatively cost-effective, providing a high-performance solution without significantly increasing costs.

Conclusion

ZSBN ceramic is undoubtedly a game-changer in the field of advanced ceramics. Its unique combination of properties, including high thermal stability, excellent electrical insulation, and mechanical strength, makes it the ultimate composite material for various demanding applications. As industries continue to seek materials that can perform under extreme conditions, ZSBN ceramic stands out as a top choice, delivering unmatched performance and reliability.

Advanced Ceramic Materials (ACM) is a reliable supplier of ZSBN ceramics. You can find quality other boron nitride composites including BN-ALN, BN-BO, PBN, and HBN on our website. Hope that you can select the most appropriate ceramics for your projects.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}