Do you have any questions? Email Us

[email protected]

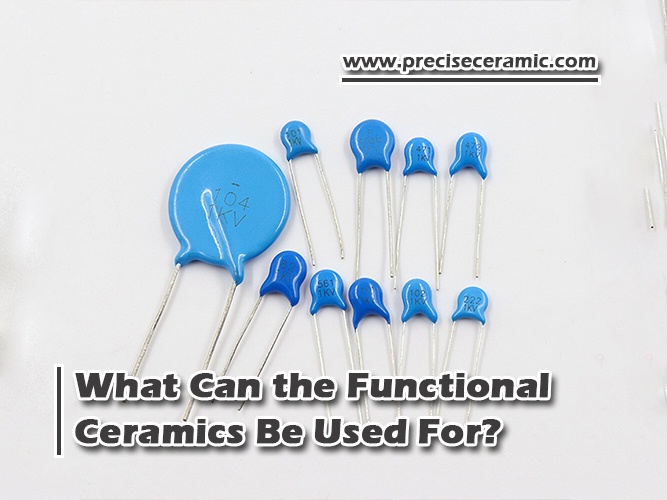

Functional ceramics are a diverse group of materials that are widely used in various applications. These ceramics are typically complex and require advanced knowledge and technology to produce. They are known for their unique properties, including high strength, hardness, and wear resistance, as well as their ability to conduct heat and electricity. Some common examples of functional ceramics include piezoelectric ceramics, superconducting ceramics, and thermal barrier coatings. These ceramics find applications in various industries as insulation materials, dielectric substance, magnetic materials, piezoceramic materials and anti-bactericidal materials. The development and advancement of functional ceramics continue to be an active area of research and innovation, as they have the potential to revolutionize many fields of technology.

At present, the commonly used electronic insulation material is Al2O3. In recent years, new electronic insulation materials, such as AlN ceramics, have many excellent performances such as high strength, high insulation, low dielectric constant and high thermal conductivity, and their main application is as a heat dissipation substrate for large-scale integrated circuits and power module circuits.

The majority of ceramic capacitor media materials used for tuning circuits, protection logic, and memory units are based on BaTiO3. The emergence of crystal boundary layer capacitors has led to a significant increase in the dielectric constant of conventional porcelain dielectric vessels, sometimes increasing by several times or even dozens of times.

The magnetic ceramic materials can be categorized as either hard magnetic materials or soft magnetic materials. Hard magnetic materials like ferrite magnets and rare earth magnets are not easily magnetized or demagnetized and are used primarily for magnets and magnetic storage elements. On the other hand, soft magnetic materials are easy to magnetize and demagnetize, and their magnetic field direction can be changed. These materials are used for alternating magnetic field response electronic components.

Piezoelectric components are widely used in various applications such as sensors, gas igniters, alarms, audio equipment, medical diagnostic equipment, and communications equipment. Advances in piezoelectric ceramic materials have led to the development of new materials such as high sensitivity, high stability piezoelectric ceramic materials, electrostrictive ceramic materials, and thermoluminescent ceramic materials. These new materials have improved performance characteristics that make them ideal for different applications, including sensors for medical and scientific purposes, as well as high-performance piezoelectric devices used in electronic and automotive industries. With continued research and development, new piezoelectric materials are expected to emerge, further expanding their applications and enhancing their performance.

The anti-bactericidal ceramic material is a new generation of functional material produced with the development of science and the civilization of society. Inorganic antimicrobials can be divided into three groups according to the mechanism of action on microorganisms. The first is made by immobilizing antibacterial metals such as silver, copper, and zinc on inorganic material carriers such as zeolite, apatite, silica gel, and glass mainly by physical adsorption or ion exchange; the second type is the photocatalytic antibacterial agent of titanium dioxide particles. Titanium dioxide can make oxygen molecules become active oxygen under light, so that water can produce reactive oxygen free radicals and play the role of antibacterial sterilization; the third kind is the anti-bactericidal material with far infrared radiation function. The antibacterial effect of the far infrared rays is limited, so this kind of material must be used together with the first two materials to have better application value.

Advanced Ceramic Materials (ACM) supplies high-quality ceramics and related products to meet our customers’ R&D and production needs. Please visit https://www.preciseceramic.com/ for more information.