Do you have any questions? Email Us

[email protected]

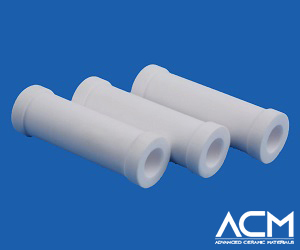

The industrial ceramic tube is a cutting-edge high-tech material that finds widespread use in various industries due to its superior characteristics. It is available in two types, high-purity and common, each designed for specific applications.

The high-purity ceramic tube is used in applications that require high chemical resistance, excellent electrical insulation, and exceptional thermal stability. They are made of ceramic materials containing more than 99% zirconia or alumina, which is usually made into molten glass to replace platinum crucible because of its high sintering temperature (1000 ℃~1900 ℃). The light transmittance and alkali-resistant metal corrosion of ceramic tubes make it used as a sodium lamp tube, as well as the integrated circuit substrates and high-frequency insulation materials in the electronics industry.

In contrast, the common ceramic tube is used in less demanding applications that require moderate thermal and chemical resistance. According to the content of alumina, the common ceramic tube system can be divided into 99 porcelain, 95 porcelain, 90 porcelain, 85 porcelain, and other varieties. Sometimes the Al2O3 content in 80% or 75% is also classified as the common ceramic tube series. Among them, 99 alumina porcelain materials are used for making high-temperature crucibles, furnace tubes and special wear-resistant materials, such as ceramic bearings, ceramic seals and water valve plates; 95 alumina porcelain is mainly used as a corrosion-resistant and wear-resistant part; in addition, some talc is often added into 85 porcelain, which can be sealed with molybdenum, niobium, tantalum metal and other metals and used as vacuum device.

Compared to traditional ceramics, industrial ceramic tubes offer several advantages.

Due to their phase-change toughening and micro-crack toughening, they have high strength and toughness, earning them the nickname "ceramic steel". In fact, their fracture toughness is the highest among all ceramics.

At room temperature, industrial ceramic tubes exhibit excellent mechanical properties. We have optimized the formula and process of zirconia to create ceramics with a fine crystal structure that boasts high hardness, strength, and toughness. These qualities give zirconia ceramics unmatched wear resistance compared to other traditional structural ceramics.

Ceramic tubes with fine grain structures can be processed to achieve very low surface roughness. This results in a reduced friction coefficient on the ceramic surface, thereby lowering the magic friction force and improving the quality of the drawn wire. The drawn wire is left smooth without burrs, making it less prone to breaking.

Industrial ceramic tubes are a high-tech material that are widely used across industries due to their superior characteristics. Compared to traditional ceramics, industrial ceramic tubes have several advantages such as high strength and toughness, unmatched wear resistance, and low surface roughness, which results in reduced friction coefficient and improved quality of drawn wire.

Advanced Ceramic Materials (ACM) supplies high-quality ceramics and related products to meet our customers’ R&D and production needs. Please visit https://www.preciseceramic.com/ for more information.