Choosing Wear-Resistant Ceramic Nozzles and Extending Their Lifespan

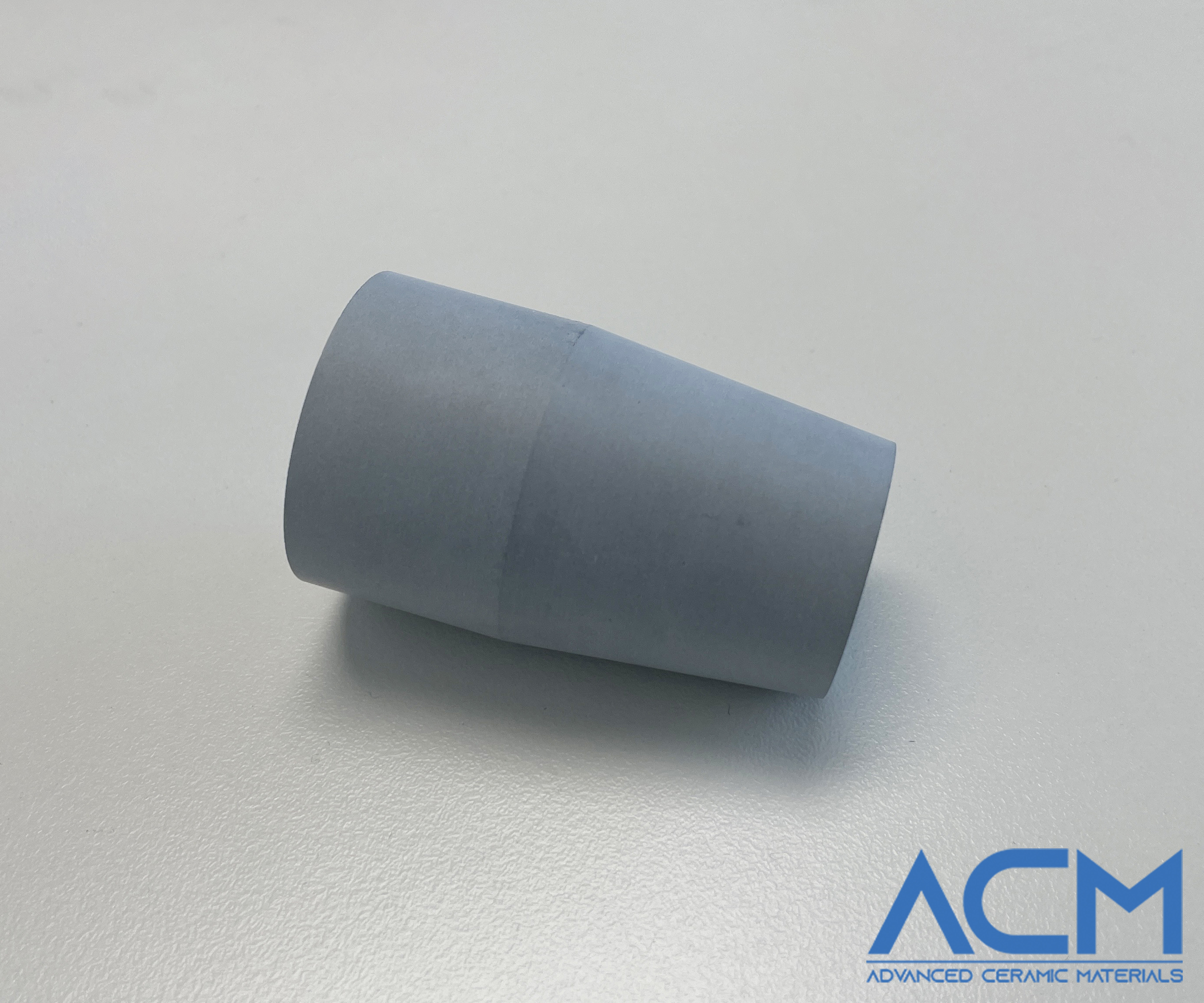

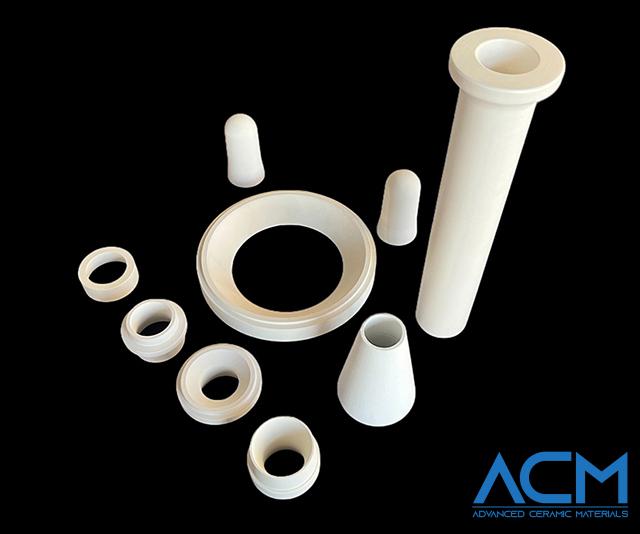

In various industrial applications—from abrasive blasting to slurry processing—nozzle wear is a serious problem. Low-hardness or standard metal components are typically susceptible to high-speed particle erosion, leading to lost efficiency, increased downtime, and higher maintenance costs. Wear-resistant ceramic nozzles present a tough option, with excellent hardness supported by long-term durability to allow them to withstand demanding operating conditions.

How Ceramic Nozzles Resist Wear

The service life of ceramic nozzles depends primarily on their resistance to particle wear and impact. Silicon carbide (SiC) and silicon nitride (Si3N4) are widely used nozzle materials due to their complementary properties.

Silicon Carbide (SiC) is well renowned for its hardness of about 9.5 on the Mohs scale. This extreme hardness makes SiC nozzles resistant to continuous bombardment by high-speed abrasive particles without any alteration of their size. In addition, SiC has good thermal conductivity and chemical stability, which guarantees performance at high-temperature or chemically aggressive applications. This places SiC uniquely well-suited for applications in which erosion by particles is the dominant wear mechanism.

Silicon Nitride (Si3N4), while being slightly less hard than SiC, is better in toughness and impact resistance. It can withstand mechanical shocks and be crack extension resistant under cyclic loading. Repeated subjecting of nozzles to particle impact or small misalignments can be handled better by Si3N4 with respect to operational life compared to harder but more brittle ceramics.

Ceramic Composites combine the characteristics of two or more materials, attaining hardness and toughness. SiC-Si3N4 composites or fiber-reinforced ceramics, for example, can minimize brittle fracture but remain highly wear-resistant. Ceramic Composites are increasingly utilized for applications with complex operating conditions where erosion and impact concurrently coexist.

Choosing the Right Material

Choosing the appropriate material is not just about hardness—it depends on the specific operating conditions:

-

High-speed, large abrasive particles: When particles move at high velocities or are relatively large, SiC nozzles are preferred. Their extreme hardness minimizes erosion and preserves nozzle geometry, reducing downtime.

-

Frequent impacts or cyclic stress: In applications with repeated particle impacts or fluctuating pressures, Si3N4 nozzles provide better toughness, resisting crack formation and extending service life.

-

Mixed conditions: When both abrasion and impact are significant, ceramic composites are recommended. They offer a compromise between hardness and toughness, maintaining performance under variable stresses.

-

Chemical or thermal considerations: For nozzles exposed to corrosive materials or high temperatures, select a material with proven chemical stability and thermal resistance. SiC generally performs well in chemically aggressive environments, while certain composites may be chosen for thermal shock resistance.

By mapping operating conditions directly to material properties, engineers and maintenance teams can make informed choices rather than relying on trial and error.

Strategies to Extend Nozzle Life

Even with the right ceramic, wear cannot be completely avoided. Proper handling and maintenance are essential:

- Installation and alignment: Correct alignment prevents uneven wear and reduces stress concentrations.

- Routine inspections: Regularly check for surface pitting, cracks, or erosion patterns. Early detection allows timely replacement before performance drops significantly.

- Operational best practices: Avoid sudden pressure surges, clogs, or abrasive spikes. Smooth, controlled operation minimizes stress on the nozzle surface.

- Protective measures: In some applications, coatings or liners can further reduce abrasion, especially when handling extremely aggressive particles.

Conclusion

Durable ceramic nozzles are a critical component of abrasive material processes. Understanding the material properties of SiC, Si3N4, and ceramic composites allows engineers to select nozzles suitable to certain operating conditions. Coupled with proper maintenance and cautious operation techniques, these materials provide increased service life, reduced downtime, and improved process efficiency. Investing money in the right ceramic nozzle is not merely a matter of material selection—it is an approach to effective, cost-saving industrial operation.

For quality ceramic materials that you can rely on, consider Advanced Ceramic Materials (ACM) as your trusted supplier. Their expertise and product quality stand behind every nozzle, helping to keep your operations efficient and cost-effective.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments

- Aluminum Oxide Ceramics: Properties and Applications

- Boron Nitride Coatings: The Solution for Molten Metal Applications