Do you have any questions? Email Us

[email protected]

Ceramic Material Comparison Chart

Explore our interactive ceramic material comparison chart below, designed to help you easily compare different materials based on their key properties, and find the best fit for your application.

READ MORE >

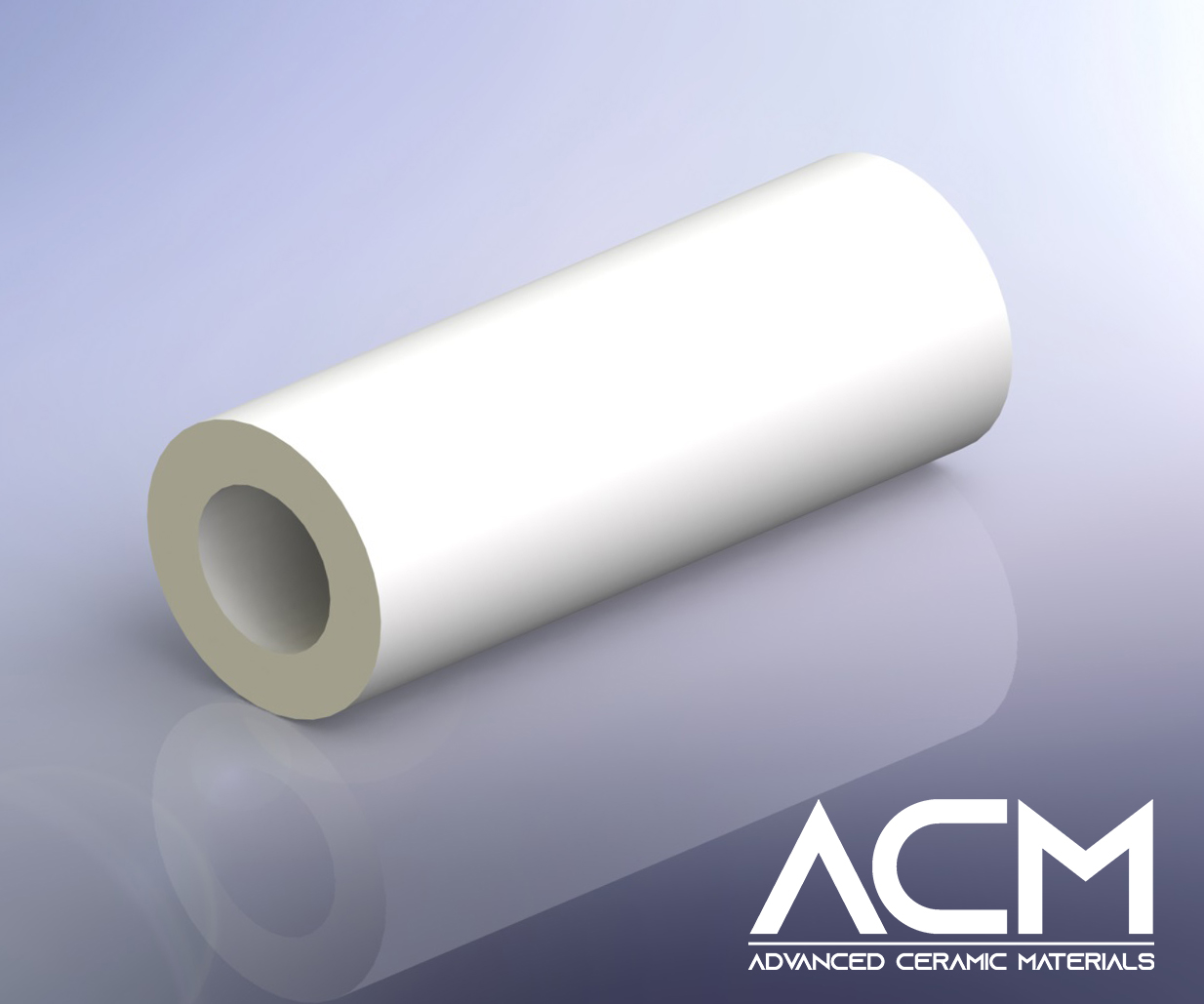

ZR3132 Silica Stabilized Zirconia Tube

Silica Stabilized Zirconia Tube Description

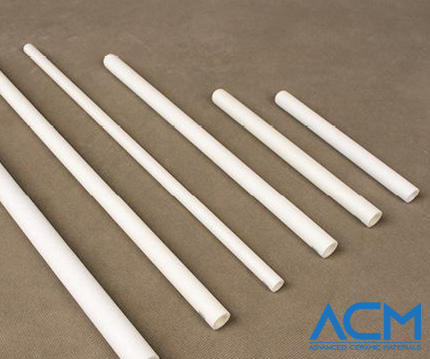

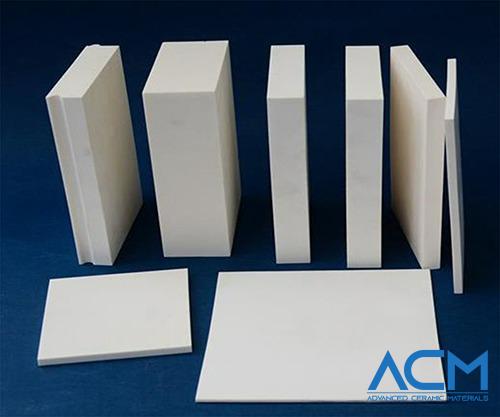

Silica-stabilized zirconia offers a reliable solution for environments containing glassy or siliceous slags within the melt. This material is commonly utilized in the melting of platinum-group alloys, thanks to its robust strength and exceptional resistance to high temperatures. It is particularly suited for challenging "dirty refining" applications where its durability shines. Tubes made from silica-stabilized zirconia are crafted from a superior grade of zircon material compared to standard zirconia tubes, ensuring enhanced performance and longevity.

Silica Stabilized Zirconia Tube Specifications

Chemical Composition

| Composition | ZrO2 | MgO | CaO | Al2O3 | TiO2 | Fe2O3 | SiO2 |

| Content % | 65.9 | 0.2 | 0.3 | 0.2 | 0.2 | 0.2 | 33 |

Physical Properties

|

Density |

3.6g/cc |

|

Porosity |

16% |

|

MOR @R.T. |

4300psi |

Silica Stabilized Zirconia Tube Applications

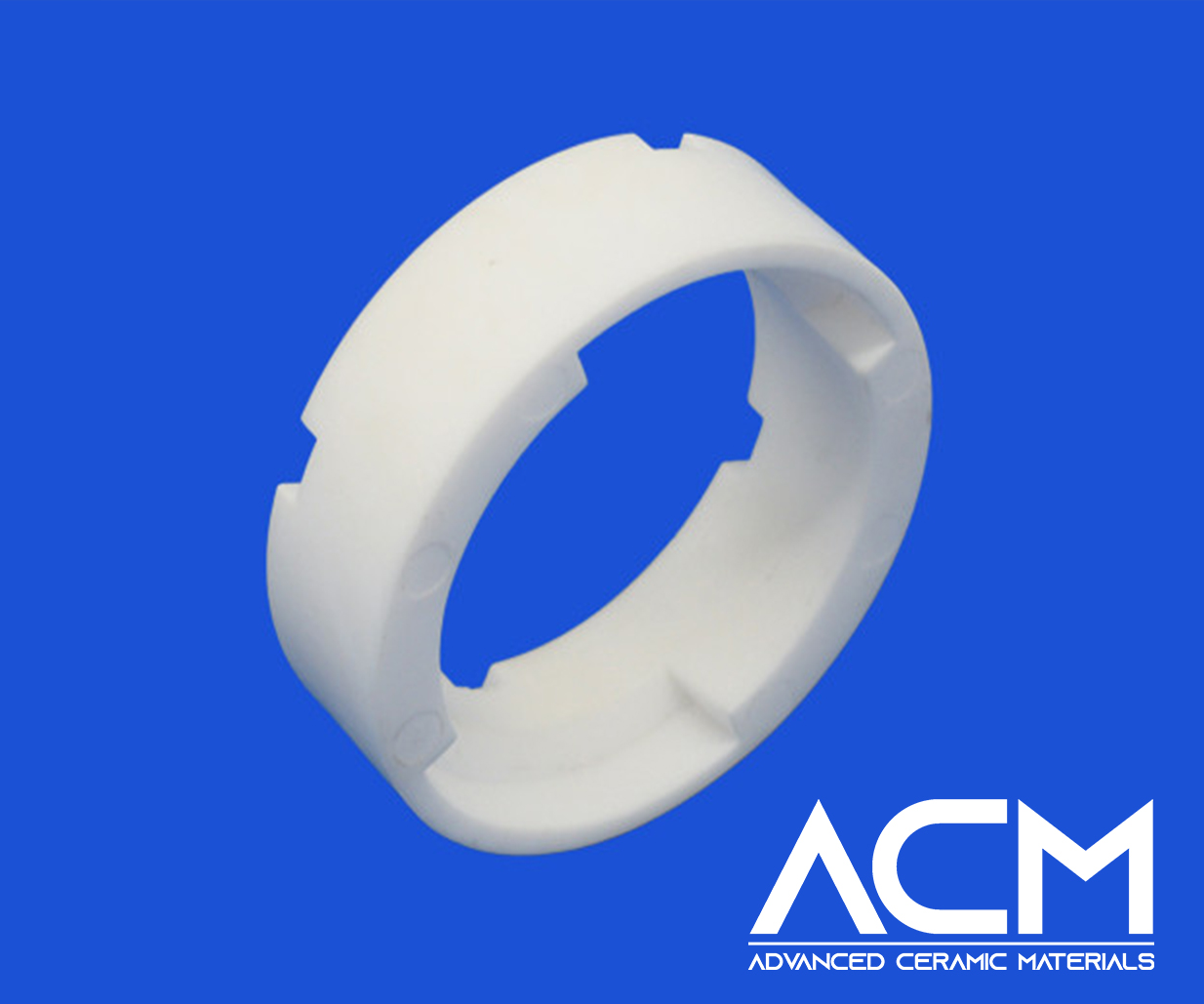

Silica Stabilized Zirconia Tubes are celebrated for their exceptional density, remarkable bending strength, and outstanding fracture toughness, making them an adaptable choice for a wide range of uses. They are highly effective in applications such as shafts, plungers, seals, automotive parts, oil exploration machinery, and insulation components in electronic devices. Additionally, these tubes are crucial for the manufacture of ceramic knives and replacement parts for ceramic hair clippers, showcasing their versatility and utility in various fields.

Silica Stabilized Zirconia Tube Packaging

Our Silica Stabilized Zirconia Tube is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Request a Quote

-

Attachment (Optional)

No file chosen

I would like to join the mailing list to receive updates from Advanced Ceramic Materials .

*e-mail address with your company's domain name is preferred. Otherwise, we may not be able to process your inquiry.

Tel : (949) 407-8904

Address : 1940 E Deere Ave #100 Santa Ana, CA 92705 U.S.A.

Main Products

Useful Links

Featured Posts

Search

Copyright © 1994-2025 Advanced Ceramic Materials owned by Oceania International LLC, All Rights Reserved.