Do you have any questions? Email Us

[email protected]

Ceramic Material Comparison Chart

Explore our interactive ceramic material comparison chart below, designed to help you easily compare different materials based on their key properties, and find the best fit for your application.

READ MORE >

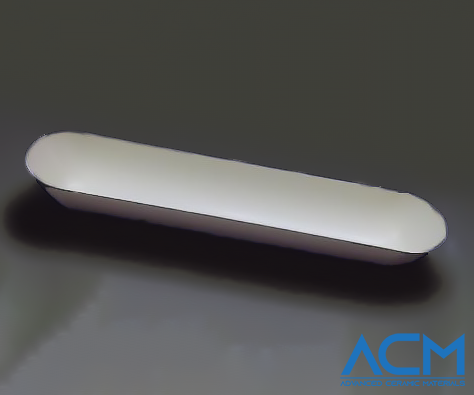

BN5749 PG Coated PBN Crucible

Description of PG Coated PBN Crucible

The PG Coated PBN Crucible offers a unique blend of pyrolytic boron nitride's thermal and chemical stability with pyrolytic graphite's high thermal conductivity and non-stick surface. This combination makes these crucibles perfect for high-purity and high-temperature applications in fields such as semiconductor manufacturing, materials research, metal processing, and optoelectronics. Their robust durability, exceptional purity, and reliable performance under extreme conditions make them essential in advanced technological and scientific applications.

Specifications of PG Coated PBN Crucible

| Property | Unit | Value |

|---|---|---|

| Density | g/cm³ | 1.95-2.22 |

| Working Temp. | ℃ | 2000 |

| Tensile Strength | MPa | 80 |

| Bending Strength | MPa | 243 |

| Material | - | PBN/PG coated |

| Color | - | Black |

Applications of PG Coated PBN Crucible

-

Semiconductor Manufacturing:

- Crystal Growth: Utilized in the production of high-purity semiconductor crystals like gallium arsenide (GaAs) and silicon carbide (SiC).

- Epitaxy: Essential in epitaxial growth processes for depositing thin films of semiconductors on substrates.

-

Materials Research:

- High-Temperature Experiments: Ideal for laboratory experiments that require high temperatures and controlled environments.

- Chemical Vapor Deposition (CVD): Used in CVD processes to grow high-purity materials and coatings.

-

Metal Processing:

- Melting and Casting: Suitable for melting and casting high-purity, reactive metals such as titanium and zirconium.

- Evaporation Sources: Serves as evaporation sources in physical vapor deposition (PVD) processes.

-

Optoelectronics:

- LED and Laser Diode Production: Applied in the fabrication of optoelectronic devices, including LEDs and laser diodes, where high purity and precision are crucial.

Packaging of PG Coated PBN Crucible

Our PG Coated PBN Crucible is meticulously handled during storage and transportation to maintain its original quality and condition.

Request a Quote

-

Attachment (Optional)

No file chosen

I would like to join the mailing list to receive updates from Advanced Ceramic Materials .

*e-mail address with your company's domain name is preferred. Otherwise, we may not be able to process your inquiry.

Tel : (949) 407-8904

Address : 1940 E Deere Ave #100 Santa Ana, CA 92705 U.S.A.

Main Products

Useful Links

Featured Posts

Search

Copyright © 1994-2025 Advanced Ceramic Materials owned by Oceania International LLC, All Rights Reserved.