Do you have any questions? Email Us

[email protected]

Advanced ceramics, also called precision ceramics, are products made from high-purity inorganic compounds with developed workmanship. Advanced ceramic products come in many shapes, such as tubes, rods, plates, boats, etc. Do you know how these ceramic components are made? Read on to find more useful information.

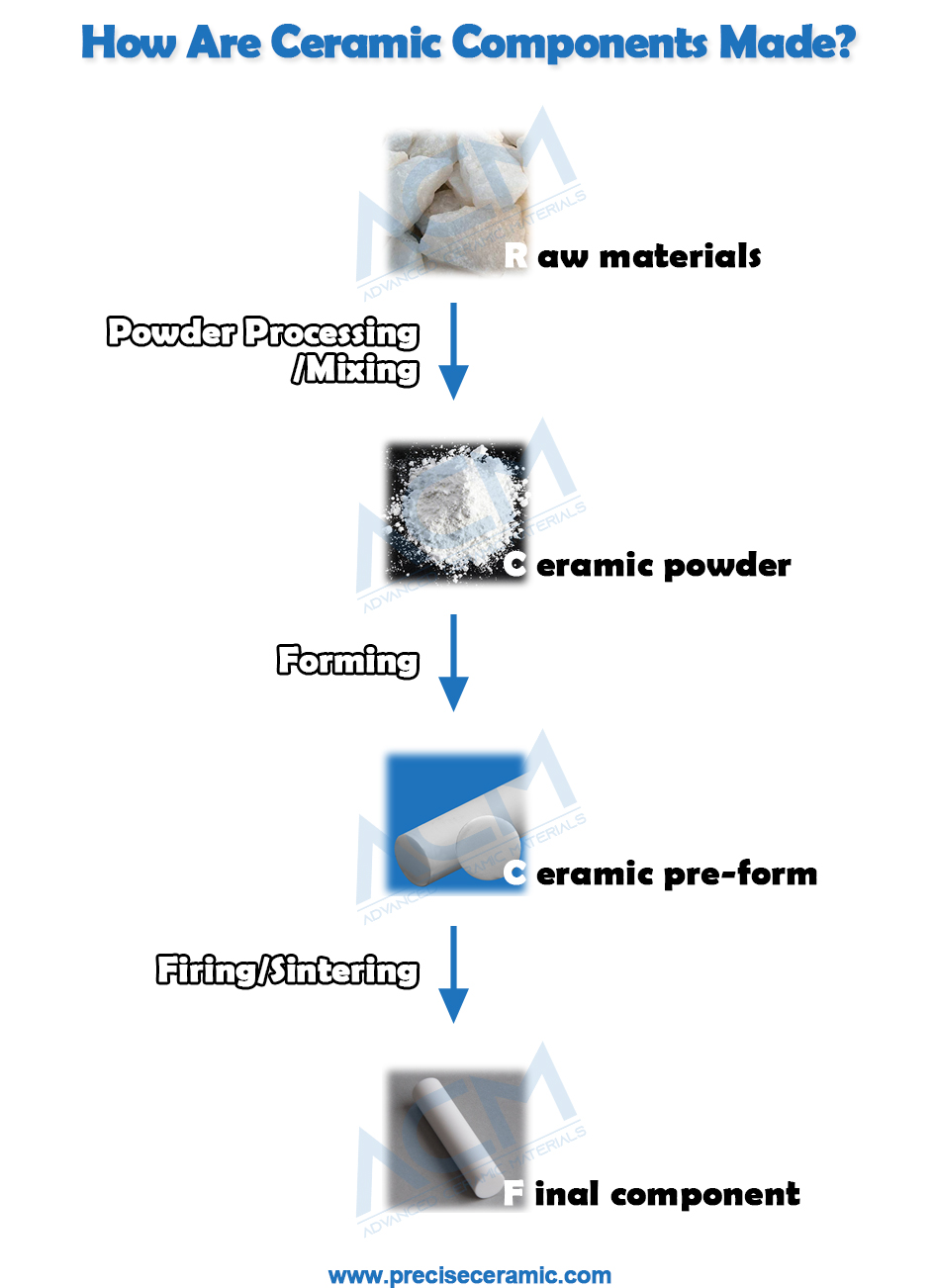

Most ceramic components are made through powder processing starting with ceramic powders. They show different shapes because of the firing/sintering of different compacted powder pre-forms.

Generally speaking, the flow for ceramic component manufacturing is shown below: RAW MATERIALS → POWDER PROCESSING/MIXING → FORMING → FIRING/SINTERING → FINAL CERAMIC COMPONENT

Infographic: How Ceramic Components Are Made

The powder processing of ceramics is very close to that of metals. Ceramic powder processing consists of powder production by milling/grinding, followed by the fabrication of the green product, which is then consolidated to obtain the final product. The powder is a collection of fine particles. The ceramic powder can be obtained by subjecting the raw materials to the following steps: pulverizing, grinding, separating impurities, mixing, and drying.

Nowadays, various powder-forming processes have been developed, such as compaction, casting, grouting, injection molding, and extrusion. These processes transform the processed powder into the desired shape, in other words, the pre-form. The pre-form is then further consolidated by sintering or firing to be the final ceramic component. In the ceramic-forming process, the addition of a binder can enhance the flowability of the powder, thereby increasing the density of the final component.

During preheating, the temperature rises to a maximum of 250°C, where organic processing additives (binders) and decomposable components evaporate. As the temperature increases to the firing temperature of the ceramic, the ceramic pre-from begins to consolidate or sinter, usually accompanied by shrinkage. This shrinkage must be taken into account or be designed in the green-state stage. Additives can be added to assist the sintering of ceramic devices. Different additives can play different roles, such as reducing the temperature, reducing sintering time, increasing ceramic density, etc.

After reading this article, you can clearly see that from ceramic raw materials to finished products need to go through the three steps of powder processing/mixing, forming, firing/sintering. This process may seem simple, but there are many different manufacturing processes involved in each step. To obtain high-quality ceramic products, strict checks are required "every minute" during the process. Thank you for reading our article and we hope it can help you to have a better understanding of the manufacturing flow of ceramic components. Advanced Ceramic Materials (ACM) supplies high-quality ceramic powder and related products to meet our customers’ R&D and production needs. Please visit https://www.preciseceramic.com/ for more information.